-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heavy 10 project

- Thread starter woodtickgreg

- Start date

- Joined

- Apr 6, 2011

- Messages

- 2,082

That does look sharp! Nice call on the paint colors.

-Ron

-Ron

- Joined

- Jun 22, 2012

- Messages

- 1,552

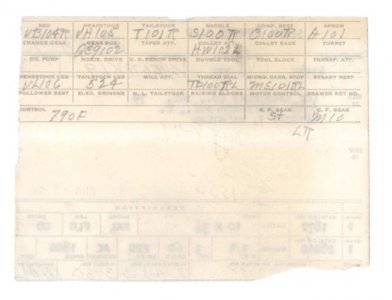

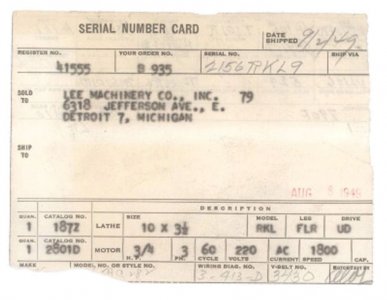

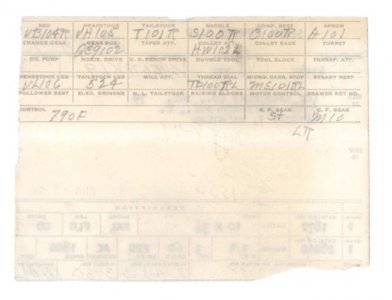

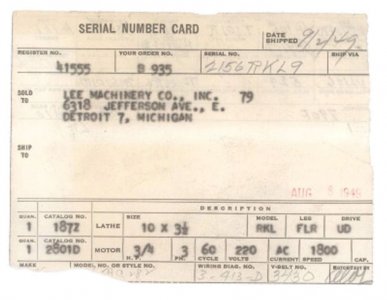

So some of you may know that I had a work injury, ruptured bicep, had surgery to reatach it and I'm home rehabing. I'm out of comishion for 4 to 8 weeks so I havn't made any further progress on the lathe. So since I don't have any progress pics to share I thought I would show the copy of the serial number build card I got from Grizzly. Grizzly is now handling parts for southbend and you can get a copy of these cards for your lathe. Some good info is on these cards, seems that mine spent it's whole life in the Detroit area, built in 1949

So some of you may know that I had a work injury, ruptured bicep, had surgery to reatach it and I'm home rehabing. I'm out of comishion for 4 to 8 weeks so I havn't made any further progress on the lathe. So since I don't have any progress pics to share I thought I would show the copy of the serial number build card I got from Grizzly. Grizzly is now handling parts for southbend and you can get a copy of these cards for your lathe. Some good info is on these cards, seems that mine spent it's whole life in the Detroit area, built in 1949

Last edited:

- Joined

- Sep 23, 2010

- Messages

- 26

Nice work Greg! Looks great. You will like the underdrive, its a good compact design. I have a 10K which is an underdrive, its a little tough to get into sometimes but once you get it set up there's not much that needs to be accessed in the cabinet other than a periodic clean and some oil.

- Joined

- Jun 22, 2012

- Messages

- 1,552

Good news! The doc has given be the green light to do a little light work in my shop. he said it would help with the rehab. So I guess I can tinker a little, maybe clean some parts, maybe a little painting. I think I can get a friend or two to help start with the rassembly of the bed, pedastal, and legs. Woo hoo! Mostly working one handed.

- Joined

- Jun 22, 2012

- Messages

- 1,552

So my first order of buis after getting the ok to do a little light work was to purchase and put together a shop cart. I needed one anyway and this would be a good test to see what I can do at this point in my rehab. It went well and I loaded it up with all the parts I need to refurb, kinda cool, when the carts empty I'll be done. Everything is tagged and bagged except for the large bits.

So my first order of buis after getting the ok to do a little light work was to purchase and put together a shop cart. I needed one anyway and this would be a good test to see what I can do at this point in my rehab. It went well and I loaded it up with all the parts I need to refurb, kinda cool, when the carts empty I'll be done. Everything is tagged and bagged except for the large bits.

Last edited:

- Joined

- Jun 21, 2012

- Messages

- 193

Lookin good! You seem to be savvy to SB's and their quirks. Glad you figured out the taper pins, those can be hell to remove if you put them in wrong (ask me how I know)! There's plenty of info out there on refurbing/restoring, especially for the heavy 10's. BradJacob over at PM did a real nice restore on his lathe....definitely an inspiration. I guess I missed the part where you needed a new headstock....was it because of the modified bearings? If you got a reasonable price on the second headstock, that might come in real handy down the road as you get some wear and tear. All in all you came out with a hell of a bargain, the name South Bend seems to add $1k to the price tag, even if it is a clapped out machine. The scraping on your compound is great. SB and other makers from that era were known to make changes quite frequently so it can be difficult to know whether something was done at the factory or by a PO. One thing I never knew is that "flame hardened ways" weren't done until sometime after the 60's....and they are ground, not scraped. But, that's not to say that scraping was done on everything prior.....some lathes were scraped, and some were not...kind of erratic for such a large company, but I guess it was according to what options the customer requested. I had a 1919 SB 14" lathe that actually had cast iron ways, not scraped or hardened, but they were hell for stout and I could barely make a mark on them when cleaning up with a scotch brite.

- Joined

- Jun 22, 2012

- Messages

- 1,552

Steve, I did end up finding another headstock with the spindle, cone pully, and bull gear. I paid $90 for it. I have not had the chance to tear it down yet but I don't think I will have the surprise I had in the first one. I don't know if it would have ran with those goofy bearings but I just couldn't see the capilary oil wicks working with them as there was a groove cut in the center of them, I just want to keep it as close to original as I can. And as far as cast iron being hard? I agree with that too! I am really having fun with this project, and it should come out nice and be a great user. I just gotta get a couple of friends over to help me assemble what I have done so far, Only got one arm as of yet. I wanted to get a couple of parts painted today but it stormed, maybe tomorrow. So far I think I have about $800 into it total, with the rebuild book and kit, and several parts that were missing or damaged. I'm gonna estimate $1000 or less for the whole project by the time its done. I think I'll get a couple of small items yet just to spiff it up, and more paint! After I get the bed, base, drip pan, and legs assembled it's on to the gearbox, everything in the gear box works, just replacing all the wicks and giving it a good cleaning and paint.Lookin good! You seem to be savvy to SB's and their quirks. Glad you figured out the taper pins, those can be hell to remove if you put them in wrong (ask me how I know)! There's plenty of info out there on refurbing/restoring, especially for the heavy 10's. BradJacob over at PM did a real nice restore on his lathe....definitely an inspiration. I guess I missed the part where you needed a new headstock....was it because of the modified bearings? If you got a reasonable price on the second headstock, that might come in real handy down the road as you get some wear and tear. All in all you came out with a hell of a bargain, the name South Bend seems to add $1k to the price tag, even if it is a clapped out machine. The scraping on your compound is great. SB and other makers from that era were known to make changes quite frequently so it can be difficult to know whether something was done at the factory or by a PO. One thing I never knew is that "flame hardened ways" weren't done until sometime after the 60's....and they are ground, not scraped. But, that's not to say that scraping was done on everything prior.....some lathes were scraped, and some were not...kind of erratic for such a large company, but I guess it was according to what options the customer requested. I had a 1919 SB 14" lathe that actually had cast iron ways, not scraped or hardened, but they were hell for stout and I could barely make a mark on them when cleaning up with a scotch brite.

- Joined

- Jun 22, 2012

- Messages

- 1,552

I finally got some work done on the painted parts, a friend came over and held everything in place for me so I could get it bolted together. This gives me a good foundation to work from now. I am still limeted in what I can do with one arm, but as long as I don't over due it the doc encourages me to work my hands. I also got the very heavy original 3 phase motor installed in the base while I had the help of my friends muscle. Still need to clean the pullys and install the v belt and adjust the tension on it, but I can do that on my own now. Next thing to do is tear down the gearbox and repaint and install new oiling wicks. The gear box has to go on before the head stock as their is a mounting screw you can't get to after the head stock is installed. Here's a few pics of todays progress.

I finally got some work done on the painted parts, a friend came over and held everything in place for me so I could get it bolted together. This gives me a good foundation to work from now. I am still limeted in what I can do with one arm, but as long as I don't over due it the doc encourages me to work my hands. I also got the very heavy original 3 phase motor installed in the base while I had the help of my friends muscle. Still need to clean the pullys and install the v belt and adjust the tension on it, but I can do that on my own now. Next thing to do is tear down the gearbox and repaint and install new oiling wicks. The gear box has to go on before the head stock as their is a mounting screw you can't get to after the head stock is installed. Here's a few pics of todays progress.

Last edited: