- Joined

- Dec 20, 2021

- Messages

- 1,071

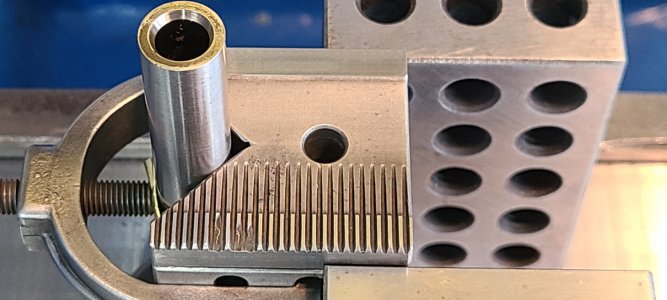

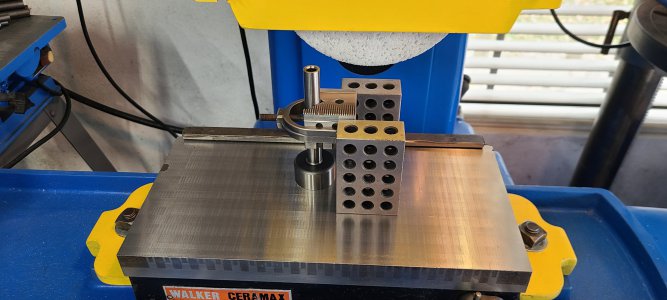

Placing the V-block on the surface plate and indicating it showed some problems. Here is where some input would be appreciated. There is perfect flatness on one side of the V-block on the mating surface. The side with the grooves for the adjustment are off .0015 lower laterally from the opposite side of block previously measured. Then it has a slope from the beginning of the teeth to the end of the teeth of .0005

So now the question is Remedy?

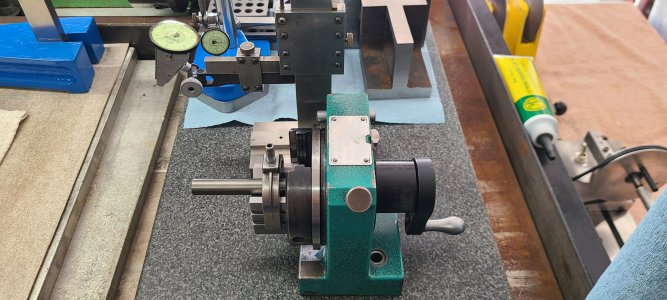

Little trouble following this, but I think I see what you are getting at. Does this error in the V block match the error you are seeing in the pin at +/-90 degrees? If you can corroborate the measured error in both setups, then you are more sure you have the culprit.

I'd probably start with just skimming everything down until the it's flat, using a cyl square as your work holding on the surface grinder. Probably want to leave the teeth in place, the little pinion may still engage and work as expected even with .0015" removed from the rack.

For $125, it's probably worth some work getting it in shape. If everything about the base checks out fine after cleaning it up, it might even be worth that $400 V block.