You could put it on wheels. I have a 5000 lb milling machine sitting out in my shop that is on castors, it actually moves pretty easy. You could do something similar. You would still want leveling screws for the lathe, but raise the screws and it would allow it to move around. I assume it wouldn't be moved often.

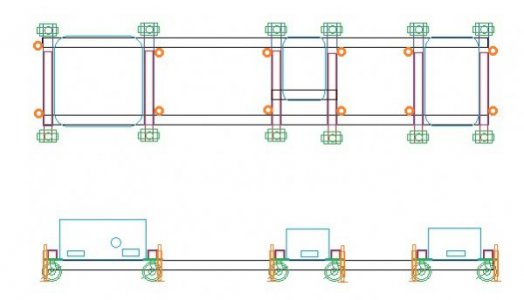

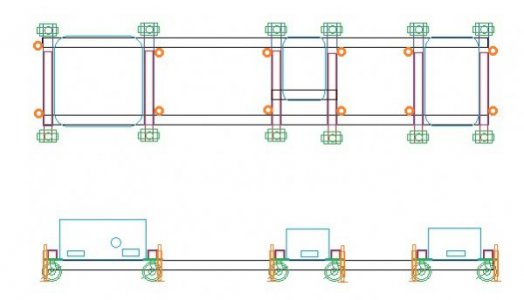

View attachment 136181

Jim, That's exactly what I was thinking. If I build a frame, say out of 4x4 square tube, put a collection of heavy duty casters on it, and also a collection of jack-screw feet, I could do that very thing. I think it wouldn't move often in the long run, but initially, as I'm getting my shop the way I want it, and as I work on the lathe itself, the ability to reposition it, pull it away from the wall to work behind it, and all of that would be indispensable and highly utilitarian. The only thing I worry about is height. On the other hand, I'm a tall fella, so that may not be too much of an issue. Playing with it yesterday, I felt like I'd be happier with the carriage wheel being about 6 inches higher anyway. I think the trick would be to build it so that a.) it's sturdy enough, b.) it's not constantly in the way, and c.) so it doesn't raise it up too much. I even thought about how if I used nested square tube, I could make the casters on the front side be mounted on removable outriggers so that once it's in place, and I've leveled it on its feet, I could pull the front caster outriggers and get them out of my way. If I needed to move it, slide 'em back in, lock 'em down, raise up the screw jacks, and away we go... Well, slowly of course... I might be over-engineering it, but here's a very, very rough, not-to-scale drawing:

Main rails are black, cross rails dark blue, removable outrigger beams red, casters green, jackscrews orange, pedestals of lathe in light blue. Again, not to scale, just spit-balling. Would probably extend main rails on ends enough to give my end jack screws two welded surfaces inside the corner. Again, just spit-balling. Advantage of under-slinging the main beams here is that I reduce the amount of raising I'm doing to the height of the casters, and not the casters PLUS the height of the beam. These casters would be 6" diameter, 1200lb each capacity, overall height of 7-1/2, so that's how much I'd be raising the lathe, plus whatever amount of leveling. As I said, I'd make the front side caster outriggers removable so that after leveling, I could pull them out and get them out of the way. The ones on the back side would stay, though again, there's be no weight on them unless I was moving it. Does this look feasible to you?

Thanks!

Edited to add: The only additional thing I might do here is break the main beams just to the right of the headstock pedestal, and nest them together, sort of like the outriggers for the front, the idea being that if I decided the bed was intolerably worn, and wanted to pull it all apart so I could take the bed to be ground, I could effectively slide the bed out, I think. I'll have to look more closely at how the bed is joined to the headstock/gearbox, etc, and see if that's even feasible...