-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G0704 CNC AC Servo Rebuild (Picture Heavy)

- Thread starter macardoso

- Start date

- Joined

- Mar 26, 2018

- Messages

- 2,725

Totally an aside, but I found a seller on eBay offering "Super Precision" .0002 TIR ER20 collets for $0.99 each

So knowing full well that these would be absolute junk I bought a few of each size, $25 in total. I figured I'd see what I could get and return the bad ones since they don't meet the specs. Just got them in the mail and I'm testing them in my best collet chuck for runout.

They all have really bad burrs from the slitting operation, but those flake off with a fingernail scrape. so far 30-40% are in the .0004 to .0008 TIR range and the rest are complete garbage with the worst reading .0085" TIR (you can visually SEE the runout!). I saved the "decent" ones in a bin for emergency use and I marked all the junk ones to be trashed/returned.

In all I ended up with 9 moderately good collets for $25. If you have patience I guess you could go this route, but I wouldn't recommend it.

https://www.ebay.com/itm/1-2-SUPER-...e=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

So knowing full well that these would be absolute junk I bought a few of each size, $25 in total. I figured I'd see what I could get and return the bad ones since they don't meet the specs. Just got them in the mail and I'm testing them in my best collet chuck for runout.

They all have really bad burrs from the slitting operation, but those flake off with a fingernail scrape. so far 30-40% are in the .0004 to .0008 TIR range and the rest are complete garbage with the worst reading .0085" TIR (you can visually SEE the runout!). I saved the "decent" ones in a bin for emergency use and I marked all the junk ones to be trashed/returned.

In all I ended up with 9 moderately good collets for $25. If you have patience I guess you could go this route, but I wouldn't recommend it.

https://www.ebay.com/itm/1-2-SUPER-...e=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

- Joined

- Mar 26, 2018

- Messages

- 2,725

Upgraded to Mach 4 build 4162 last night without incident. I moved all my serial and servo scripts into two modules which are loaded when you open Mach 4. The benefits of this are that you get to use a "class" in your programming, and that the screen load script doesn't have a ton of functions just hanging around (makes it hard to read).

My serial module contains 5 functions and my servo module contains 28. I went through the list of available serial commands for the drive and created a Mach 4 interface to any of them that I thought might ever be used. Easy to add more in the future.

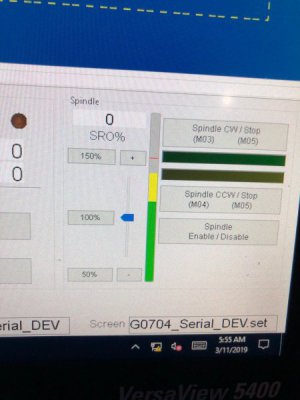

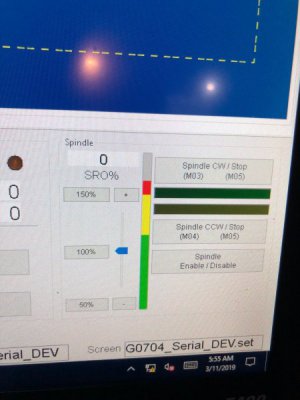

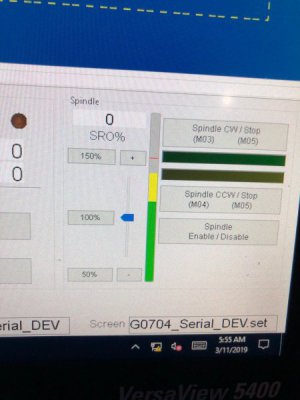

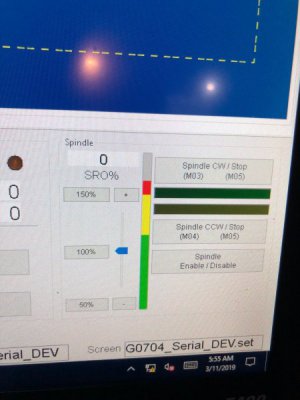

I made a special function mcServo.SpindleLoad2Reg() which queries the servo drive for the torque consumption averaged over 100ms and copies the data into a global register. I will probably do some math to convert the torque to power since the torque curve drops a bit past 3800rpm. The function is called from the PLC script 10 times per second. I added a bar gauge to the spindle section of the screen which reads the global register and displays the real time torque on the spindle (roughly analogous to load). The gauge fills up with green to 100%, yellow to 150% and red to 200%. In reality, the register goes up to 250% but I didn't feel like having it go that high since I won't be machining in the red. The refresh is pleasant to watch and it is very responsive to me twisting the spindle nose.

After I took pictures, I also added a spindle orient button and a text display for the motor temperature. I would love to add some thermocouples to the spindle bearings, but this is good enough for now.

I think having a good understanding of the spindle load will help me fine tune my toolpath settings.

My serial module contains 5 functions and my servo module contains 28. I went through the list of available serial commands for the drive and created a Mach 4 interface to any of them that I thought might ever be used. Easy to add more in the future.

I made a special function mcServo.SpindleLoad2Reg() which queries the servo drive for the torque consumption averaged over 100ms and copies the data into a global register. I will probably do some math to convert the torque to power since the torque curve drops a bit past 3800rpm. The function is called from the PLC script 10 times per second. I added a bar gauge to the spindle section of the screen which reads the global register and displays the real time torque on the spindle (roughly analogous to load). The gauge fills up with green to 100%, yellow to 150% and red to 200%. In reality, the register goes up to 250% but I didn't feel like having it go that high since I won't be machining in the red. The refresh is pleasant to watch and it is very responsive to me twisting the spindle nose.

After I took pictures, I also added a spindle orient button and a text display for the motor temperature. I would love to add some thermocouples to the spindle bearings, but this is good enough for now.

I think having a good understanding of the spindle load will help me fine tune my toolpath settings.

- Joined

- Mar 26, 2018

- Messages

- 2,725

In preparation for a prototype job that I recently started on, I ran a test part on my CNC using the spindle as a lathe (tools clamped in the vise). Unfortunately I cannot post any pictures from the job directly, but I will try to get some of the setup in general.

I have never used MasterCam lathe and was concerned about the learning curve to generate the code necessary. It took me less than 30 minutes to generate the geometry and toolpaths, modify a post processor to output in radius mode, and post code ready to run. The machine axes are all already in the correct setup (Z and X are the same as a real lathe, as well as their directions) and the Y axis can be used to adjust tool centerline or index to a new tool. Instead of using tool offsets to change tools, a new work offset is defined for each tool and the G54-59 call is placed in the code where a toolchange would occur.

I have purchased a Thinbit grooving tool to make all of the grooves on the part and I am excited to see how it works.

I have never used MasterCam lathe and was concerned about the learning curve to generate the code necessary. It took me less than 30 minutes to generate the geometry and toolpaths, modify a post processor to output in radius mode, and post code ready to run. The machine axes are all already in the correct setup (Z and X are the same as a real lathe, as well as their directions) and the Y axis can be used to adjust tool centerline or index to a new tool. Instead of using tool offsets to change tools, a new work offset is defined for each tool and the G54-59 call is placed in the code where a toolchange would occur.

I have purchased a Thinbit grooving tool to make all of the grooves on the part and I am excited to see how it works.

- Joined

- Mar 26, 2018

- Messages

- 2,725

Long time without a post, but I just finished up a prototype job that required me to use the mill as a CNC lathe with tools ganged in a vise. Machine worked great! As mentioned above, one of the tools I picked out was a Thinbit Groove N' Turn to do some narrow slotting in the parts. This worked great and I was amazed by the quality of a name brand tool.

I also opted to do all of the CNC turning (in 304 SS) with a CCGX32.50 insert for Aluminum. The workholding rigidity was pretty poor due to the shape of the part, so I wanted to keep the cutting forces very low. It actually worked great and left near mirror surface finishes. DOC was only .005 and that easily formed a chip and never rubbed. Tool life was very low (about 5 parts per edge) and still left good finishes but would audibly begin to chatter. At $6 an insert from Shars this was very economical. Maybe I could have found a fancy superfinishing insert for SS, but these got the job done quick and easy.

Getting married in 11 days so probably won't be in the shop for a little while. Can't say I can complain

I also opted to do all of the CNC turning (in 304 SS) with a CCGX32.50 insert for Aluminum. The workholding rigidity was pretty poor due to the shape of the part, so I wanted to keep the cutting forces very low. It actually worked great and left near mirror surface finishes. DOC was only .005 and that easily formed a chip and never rubbed. Tool life was very low (about 5 parts per edge) and still left good finishes but would audibly begin to chatter. At $6 an insert from Shars this was very economical. Maybe I could have found a fancy superfinishing insert for SS, but these got the job done quick and easy.

Getting married in 11 days so probably won't be in the shop for a little while. Can't say I can complain

- Joined

- Nov 23, 2014

- Messages

- 2,634

Congrats on the upcoming nuptials! Maybe adapt the spindle to dispense icing for cake decorating? Or CNC the bride and groom on top of the cake? Or add a 4th axis to the mill (wouldn't that be a fantastic wedding present) so you can engrave a nice ring? Enjoying your string.Long time without a post, but I just finished up a prototype job that required me to use the mill as a CNC lathe with tools ganged in a vise. Machine worked great! As mentioned above, one of the tools I picked out was a Thinbit Groove N' Turn to do some narrow slotting in the parts. This worked great and I was amazed by the quality of a name brand tool.

I also opted to do all of the CNC turning (in 304 SS) with a CCGX32.50 insert for Aluminum. The workholding rigidity was pretty poor due to the shape of the part, so I wanted to keep the cutting forces very low. It actually worked great and left near mirror surface finishes. DOC was only .005 and that easily formed a chip and never rubbed. Tool life was very low (about 5 parts per edge) and still left good finishes but would audibly begin to chatter. At $6 an insert from Shars this was very economical. Maybe I could have found a fancy superfinishing insert for SS, but these got the job done quick and easy.

Getting married in 11 days so probably won't be in the shop for a little while. Can't say I can complain

Bruce

- Joined

- Mar 26, 2018

- Messages

- 2,725

Also this past job was the destroyer of tools (I've never worked in stainless before)

The following were added to the graveyard:

The following were added to the graveyard:

- 1 - CCMT Insert (cut above centerline)

- 3 - CCGX inserts (worn edges, fine by me)

- 1 - M3.5x0.6 tap (stuck in the part)

- 1 - 3mm carbide ball endmill (CNC crash due to code error)

- 1 - carbide center drill (fed too fast)

- Chipped the edge off my parting tool (reground)