Haven't parted anything yet. Have the blades / holders, etc. To your initial question, the turning / facing to get a barrel tenon set up have been fine.how about parting?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Facets in my 16 TPI Threads - Need some help!

- Thread starter TX COWDOC

- Start date

- Joined

- Dec 26, 2015

- Messages

- 2,154

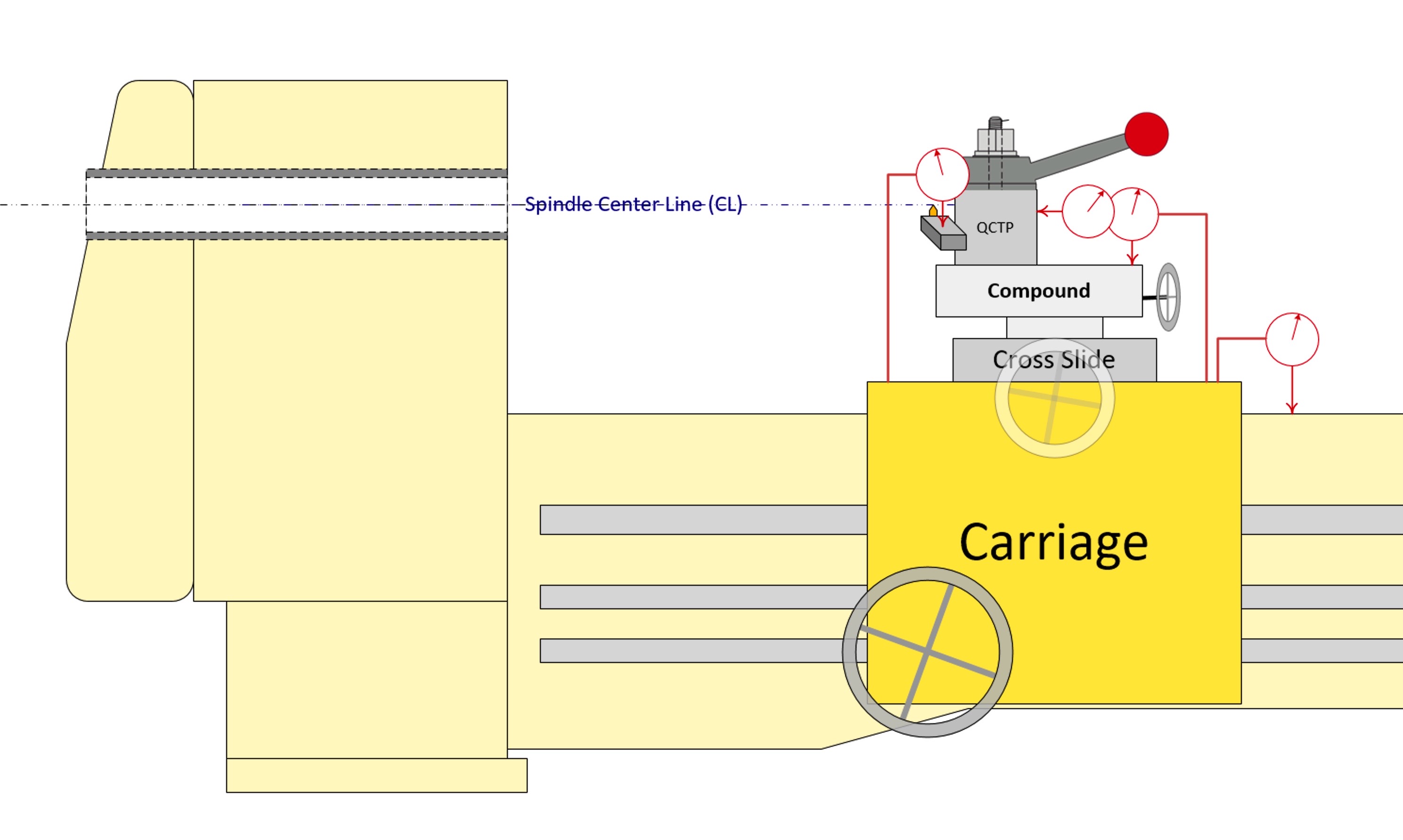

I recommend what savarin suggests. Your swarf tells me the cutting tool is not engaging consistently - probably because you are below the minimum SFM or the DOC is too shallow. Cut a relief and thread into it at twice the RPM. Repeat with twice the DOC. Repeat plunging straight in Instead at 30-degrees. It could also be rigidity issues like compound flex, QCTP flex, QC tool holder rocking at the dovetail, etc - all of which could be verified with a 0.0005” DTI. I would start by instrumenting the setup and verify you don‘t have rigidity issues at the cutter. Then start experimenting with more aggressive F & S.

So place the DTI tip on top of the threading tool and monitor for movement while threading?It could also be rigidity issues like compound flex, QCTP flex, QC tool holder rocking at the dovetail, etc - all of which could be verified with a 0.0005” DTI. I would start by instrumenting the setup and verify you don‘t have rigidity issues at the cutter. Then start experimenting with more aggressive F & S.

- Joined

- Dec 26, 2015

- Messages

- 2,154

We all understand you ultimately don't want a big thread relief, but you need to experiment first to discover what's going wrong with your setup. If you're not comfortable threading at 200 RPM without a thread relief area to land in, then cut a thread relief and try it anyway. This is a process of eliminating all the variables one step at a time. Like I said before, I would start by putting sensitive indicators on the cutting platforms and seeing what, if anything is jittering around during the cutting opeartions. I can't imagine getting the kind of swarf you're getting and not being able to see the source of the intermittent cutting with sensitive indicators on your setup.I bought the lathe to build rifles. I do not intend to have a relief between the lug seat and tenon threads. I've seen a few videos of machinists (like Joe P.) threading that way. I built my 1st rifle this summer using carbide at 65 RPM. Never a problem. There is an issue here that must be addressed. Thanks for the feedback.

Will do tomorrow evening and report back.We all understand you ultimately don't want a big thread relief, but you need to experiment first to discover what's going wrong with your setup. If you're not comfortable threading at 200 RPM without a thread relief area to land in, then cut a thread relief and try it anyway. This is a process of eliminating all the variables one step at a time. Like I said before, I would start by putting sensitive indicators on the cutting platforms and seeing what, if anything is jittering around during the cutting opeartions. I can't imagine getting the kind of swarf you're getting and not being able to see the source of the intermittent cutting with sensitive indicators on your setup.

- Joined

- Dec 26, 2015

- Messages

- 2,154

Here are the control surfaces I would instrument with a 0.0001" or 0.0005" indicator (tenths):

Do one at a time and observe the fluctuation in the indicator during the cutting operation. This should tell you if you have rigidity issues.

- Carriage to bedways

- Carriage to compound

- Carriage to top or side of QCTP

- Carriage to top of the A.R. Warner threading toolholder.

Do one at a time and observe the fluctuation in the indicator during the cutting operation. This should tell you if you have rigidity issues.

- Joined

- Mar 22, 2013

- Messages

- 511

As Always, David and others have some excellent points to try. Are any of you guys looking for a job? We have some great people here, but definitely are looking for a few more experts to take some weight from my shoulders! (Not kidding, but back to figuring out the problem)

I will post my thinking here, just to keep it all in one place, and so others can use this as a resource in the future. If anyone has more comments or thinks any of my points are not correct, please feel free to chime in, I have been doing this a long time, but I am certainly not perfect, no one is.

1. This helps with eliminating the single phase motor vibration: Run the machine at the speed you are cutting, leave the tool engaged in the work, cut the motor power (Put the spindle on/off lever in off). Leave the tool to keep cutting and as it coasts to a stop, see if the pattern goes away right away. If so, its probably vibration from the single phase motor. You may have to up the speed to get it to coast enough to see if this makes a difference. Are you having other finish problems though? It would not usually just show up in threading. **I recommend this with HSS tools, less likely to snap as it slows down - Wear Glasses (Always), and not too heavy of a cut.

2. Speeds and DOC: What speed are you running at? I have been through this with people before, and the only way I could reproduce this exact type of pattern was going very slow and deep cuts. Reproduced on my known good 1440GT that we turn good parts out on all the time. I would say try around 200 RPM and lighter cuts, see what you end up with just to try it.

3. Are you using the same cutting oil that Bamban is using, I see you have the same material. Same exact cutter, speeds, Depth, etc?

4. Eliminate the leadscrew bearings, doubtful, but eliminating every link: Try a left hand thread. See if its identical. Ive never had this change in a finish problem,, but just trying to eliminate things. Once I had a person who had a strange lump in a thread once every so often. This was a much larger lathe. Ended up being chips in a thrust bearing in the leadscrew. Every so often I guess the balls would run the chip over and it would move ever so slightly. But he was making mirror finishes in these larger threads on a part, so it was easy to spot. Probably would not have been noticed otherwise.

5. Sort of eliminate the compound moving, but this goes with Davids indicator method he suggested above. Try without using the compound. Put it on 90 degrees (Parallel with the work, the compound will show 0 degrees), backed up so no overhang. Tighten the gib lock. Thread like this and see if that takes care of it. But this goes along with the indicators David Best suggested to see if anything moves.

6. Here is another way to think of it. Your turning finishes are fine from what you said. Threading is the problem. There is no difference in whats holding any of the tools. Its nothing more than the tool moving along the work piece at a different rate and a different shape. Try putting it in a coarse feed and feeding your threading tool at the same 65 RPM. Does it cut OK then? You cant get thread depth like this, but can get an idea how its cutting.

7. Was the original problem fixed in steel, but now this is in the 416? Reading through it looks like it was improved and working fine, but now its a problem again. So Is this still happening in aluminum or other materials now? Or only in the 416? If so, can you make a quick video of the chip forming?

8. The chip curls in the pictures look very deep to me, just a note. If you are using your DRO to get back to zero, try the dial instead, just to eliminate anything there. That chip seems way deeper than it should me to me.

9. Try what the others have said about the threading with the relief. No you didnt buy it to do that, but its a bit step in elimination or narrowing things down.

I tried to make it easy to follow, if there are any questions about the steps or what I am thinking, feel free to let me know.

I will post my thinking here, just to keep it all in one place, and so others can use this as a resource in the future. If anyone has more comments or thinks any of my points are not correct, please feel free to chime in, I have been doing this a long time, but I am certainly not perfect, no one is.

1. This helps with eliminating the single phase motor vibration: Run the machine at the speed you are cutting, leave the tool engaged in the work, cut the motor power (Put the spindle on/off lever in off). Leave the tool to keep cutting and as it coasts to a stop, see if the pattern goes away right away. If so, its probably vibration from the single phase motor. You may have to up the speed to get it to coast enough to see if this makes a difference. Are you having other finish problems though? It would not usually just show up in threading. **I recommend this with HSS tools, less likely to snap as it slows down - Wear Glasses (Always), and not too heavy of a cut.

2. Speeds and DOC: What speed are you running at? I have been through this with people before, and the only way I could reproduce this exact type of pattern was going very slow and deep cuts. Reproduced on my known good 1440GT that we turn good parts out on all the time. I would say try around 200 RPM and lighter cuts, see what you end up with just to try it.

3. Are you using the same cutting oil that Bamban is using, I see you have the same material. Same exact cutter, speeds, Depth, etc?

4. Eliminate the leadscrew bearings, doubtful, but eliminating every link: Try a left hand thread. See if its identical. Ive never had this change in a finish problem,, but just trying to eliminate things. Once I had a person who had a strange lump in a thread once every so often. This was a much larger lathe. Ended up being chips in a thrust bearing in the leadscrew. Every so often I guess the balls would run the chip over and it would move ever so slightly. But he was making mirror finishes in these larger threads on a part, so it was easy to spot. Probably would not have been noticed otherwise.

5. Sort of eliminate the compound moving, but this goes with Davids indicator method he suggested above. Try without using the compound. Put it on 90 degrees (Parallel with the work, the compound will show 0 degrees), backed up so no overhang. Tighten the gib lock. Thread like this and see if that takes care of it. But this goes along with the indicators David Best suggested to see if anything moves.

6. Here is another way to think of it. Your turning finishes are fine from what you said. Threading is the problem. There is no difference in whats holding any of the tools. Its nothing more than the tool moving along the work piece at a different rate and a different shape. Try putting it in a coarse feed and feeding your threading tool at the same 65 RPM. Does it cut OK then? You cant get thread depth like this, but can get an idea how its cutting.

7. Was the original problem fixed in steel, but now this is in the 416? Reading through it looks like it was improved and working fine, but now its a problem again. So Is this still happening in aluminum or other materials now? Or only in the 416? If so, can you make a quick video of the chip forming?

8. The chip curls in the pictures look very deep to me, just a note. If you are using your DRO to get back to zero, try the dial instead, just to eliminate anything there. That chip seems way deeper than it should me to me.

9. Try what the others have said about the threading with the relief. No you didnt buy it to do that, but its a bit step in elimination or narrowing things down.

I tried to make it easy to follow, if there are any questions about the steps or what I am thinking, feel free to let me know.

- Joined

- Feb 20, 2019

- Messages

- 358

A thread relief is not always a bad thing on a barrel. Some actions, that last thread, can actually interfere with the barrel making up tightly. The only downside is if you set the barrel back later in it's life and might have a gap in the threads but it's more cosmetic than a mechanical problem.

Not related to your problem, but I read you were building a 6.5 PRC. I wonder if your planning on using a SAAMI spec reamer? Seems there is a real problem if you reload. By the time you fire 2 or 3 rounds, you can't resize brass enough to avoid heavy bolt lift/clickers. There have been some reamer prints posted that increase the dimension at the 0.200 datum that fix the issue. Just a heads up.

Not related to your problem, but I read you were building a 6.5 PRC. I wonder if your planning on using a SAAMI spec reamer? Seems there is a real problem if you reload. By the time you fire 2 or 3 rounds, you can't resize brass enough to avoid heavy bolt lift/clickers. There have been some reamer prints posted that increase the dimension at the 0.200 datum that fix the issue. Just a heads up.

Last edited:

Similar threads

- Replies

- 47

- Views

- 2K

[How do I?]

Need help figuring out my thread chasing dial

- Replies

- 19

- Views

- 4K

- Replies

- 5

- Views

- 1K

- Replies

- 2

- Views

- 3K