-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Extreme Air Mail! Mailing Tube Rocket Project!

- Thread starter Weldo

- Start date

E30!!!

R

Wondering why anything less than the biggest would even be mentioned..........................

- Joined

- Sep 7, 2019

- Messages

- 674

Honestly after trying a launch on a D12, I may try a C11. I’ve never run a sim on that one yet.

The point of this build was not to attain max altitude but rather to make a successful launch of a vehicle at or near the maximum possible weight for a given engine. Based on simulations I believe my design is about there. It should make for a somewhat slow lift off and an interesting low altitude flight.

Of course I’m still pretty new in the hobby so it may all go belly up!

The point of this build was not to attain max altitude but rather to make a successful launch of a vehicle at or near the maximum possible weight for a given engine. Based on simulations I believe my design is about there. It should make for a somewhat slow lift off and an interesting low altitude flight.

Of course I’m still pretty new in the hobby so it may all go belly up!

- Joined

- Sep 7, 2019

- Messages

- 674

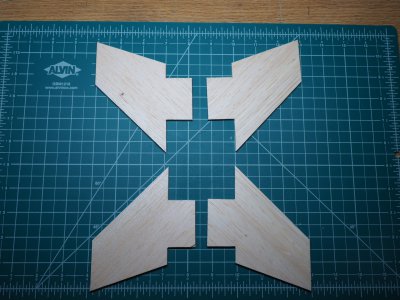

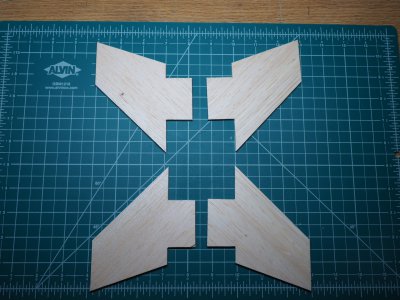

OK fins are made!

I had another slow day at work and had time to run to the hobby shop. A sheet of balsa 6" x 36" x 1/8" was only $5! I only used about 10" of it. The fin tenons will have to be trimmed to fit later, they are left long.

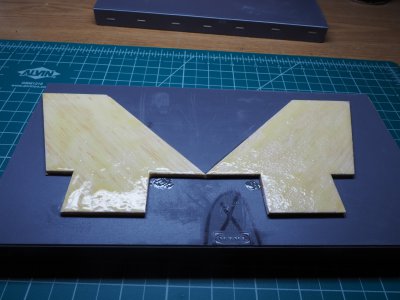

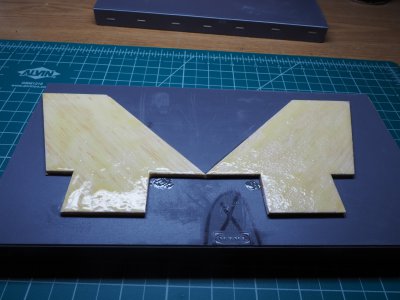

Here's the treatment I've been giving my rocket fins lately. I read about making a "fin press" in one of Apogee's newsletters. In the article the author used epoxy but I tried this polyurethane glue from Titebond and it gives me good results. It foams up to fill voids and maybe it even penetrates the grain a bit. It dries to a smooth hard shell when cured in the press.

The plastic is polypropylene or HDPE cutting mats from IKEA. $1.99 for two mats if I recall. They are mounted to a piece of 1x6 poplar.

I don a pair of nitrile gloves and the glue is spread on with a plastic Bondo spreader. The glue could've been a little heavier in the following pic but hopefully with clamping it'll even out over the surface.

Usually with smaller fins I'd just put a heavy object on the top piece of the press but for these fins I'll apply 6 heavy C clamps for 24 hours.

Tomorrow I'll do the other two fins and then figure out how to cut accurate slots in the body tube.

I had another slow day at work and had time to run to the hobby shop. A sheet of balsa 6" x 36" x 1/8" was only $5! I only used about 10" of it. The fin tenons will have to be trimmed to fit later, they are left long.

Here's the treatment I've been giving my rocket fins lately. I read about making a "fin press" in one of Apogee's newsletters. In the article the author used epoxy but I tried this polyurethane glue from Titebond and it gives me good results. It foams up to fill voids and maybe it even penetrates the grain a bit. It dries to a smooth hard shell when cured in the press.

The plastic is polypropylene or HDPE cutting mats from IKEA. $1.99 for two mats if I recall. They are mounted to a piece of 1x6 poplar.

I don a pair of nitrile gloves and the glue is spread on with a plastic Bondo spreader. The glue could've been a little heavier in the following pic but hopefully with clamping it'll even out over the surface.

Usually with smaller fins I'd just put a heavy object on the top piece of the press but for these fins I'll apply 6 heavy C clamps for 24 hours.

Tomorrow I'll do the other two fins and then figure out how to cut accurate slots in the body tube.