Fin time!

Below are the fins as removed from the first pressing where I used the HDPE sheets. The left one is trimmed up with a utility knife.

This is the one that gave me problems. You can see the corner that cracked off upon removal from the press and the strips of glue that were yet uncured upon removal.

Here's the fins from the second pressing with the silicone mat. They were much easier to remove than from the HDPE. Also there was no uncured glue after the 24 hours wait. I think the light application of moisture to the balsa is what helped that. This glue cures by exposure to moisture.

Notice the somewhat darker stripes. I don't know if the glue was thicker here or there was some waviness in the silicone. It feels smooth and I don't think it's an issue. Maybe the grain absorbed the glue differently here?

I also noticed one area that had thinned out, presumably from excess clamping pressure. Maybe I need a more even way to clamp. This pic is sighting down the trailing edge from root to tip.

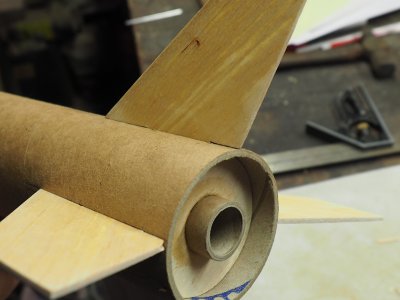

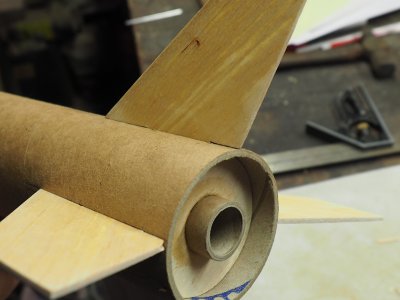

After they are all cleaned up the fit is checked. They go in snugly!

Here's how they fit with the motor mount installed. A little trimming is in order.

The fins were sanded down to just touch the motor mount. I should be able to get some glue from the fin to the motor mount as well as the body tube to make a very solid connection.

This is the most robust rocket I've ever handled!

I still want to round over all the edges before gluing. Also I think I should glue in the bulkhead first since it'll be a bit more fiddly.