-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Extreme Air Mail! Mailing Tube Rocket Project!

- Thread starter Weldo

- Start date

- Joined

- Sep 7, 2019

- Messages

- 674

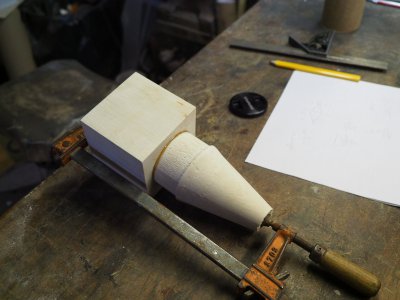

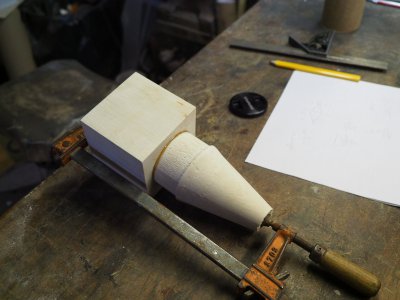

Part Duex! I know there's a good nose cone in there somewhere!

I'll let this chooch overnight and then try again on the lathe from start to finish, none of that hand work nonsense! The glue used is a polyurethane from Titebond. It foams and expands as it cures so it's supposedly good for end grain joints. Also as an aside I've been using it to coat balsa wood fins with pretty good success.

I'll try to drill and glue in a bigger dowel then turn the whole thing to the largest OD I can get from the square. Then I'll set the compound for 14.5 degrees and whittle away at the angled part, turning at least 6" into a large cone.

Finally I'll turn down the shoulder to my tube's ID dimension, again leaving a few thousandths for sanding. Any excess length should then be able to be cut off the shoulder at the base of the nose cone.

I think that will be the most accurate way to do it.

I've noticed over the years that a lot of my problems stem from impatience. In an effort to learn from my past mistakes I'm just gonna buckle down and take light cuts, reposition the carriage as needed and take my time.

Anyone got any recommendations for a HSS cutter profile for soft wood?

I'll let this chooch overnight and then try again on the lathe from start to finish, none of that hand work nonsense! The glue used is a polyurethane from Titebond. It foams and expands as it cures so it's supposedly good for end grain joints. Also as an aside I've been using it to coat balsa wood fins with pretty good success.

I'll try to drill and glue in a bigger dowel then turn the whole thing to the largest OD I can get from the square. Then I'll set the compound for 14.5 degrees and whittle away at the angled part, turning at least 6" into a large cone.

Finally I'll turn down the shoulder to my tube's ID dimension, again leaving a few thousandths for sanding. Any excess length should then be able to be cut off the shoulder at the base of the nose cone.

I think that will be the most accurate way to do it.

I've noticed over the years that a lot of my problems stem from impatience. In an effort to learn from my past mistakes I'm just gonna buckle down and take light cuts, reposition the carriage as needed and take my time.

Anyone got any recommendations for a HSS cutter profile for soft wood?

As a long time model airplane builder I should be able to offer some advice. Shaping balsa should be done with a mini wood plane, slow and carefully. Use Evercoat afterwards to fill in your low points and sand it to perfection. Evercoat is very very light, perfect for something that flys.

Here is a build of mine completely from scratch, every piece is balsa wood and hand cut and sanded. Evercoat body filler, fiberglass cloth covered, painted and sealed with automotive clear coat.

Here is a build of mine completely from scratch, every piece is balsa wood and hand cut and sanded. Evercoat body filler, fiberglass cloth covered, painted and sealed with automotive clear coat.

- Joined

- Jan 2, 2014

- Messages

- 9,347

Anyone got any recommendations for a HSS cutter profile for soft wood?

I know it's not what you meant, but .........a rasp or file?

-brino

- Joined

- Jan 2, 2014

- Messages

- 9,347

Here is a build of mine completely from scratch, every piece is balsa wood and hand cut and sanded. Evercoat body filler, fiberglass cloth covered, painted and sealed with automotive clear coat.

@Dhal22,

That is beautiful!

I just wish I could click the thumbnail for a bigger picture......

-brino

@Dhal22,

That is beautiful!

I just wish I could click the thumbnail for a bigger picture......

-brino

Thanks, let me try to upload a better photo.

Enlarged it but blurry. Maybe on another thread as we are drifting on OP's thread.

Build thread here:

Build thread here:

Another Blue Angel build - RCU Forums

Classic RC Pattern Flying - Another Blue Angel build - Seduced by the exquisite beauty of the MK Blue Angel and equally so the craftsmanship of 8178's build, I have ordered the plans, wing cores and canopy from Carolina Custom Aircraft carolinaaircraft@earthlink.net Although I am in the...

www.rcuniverse.com

- Joined

- Sep 7, 2019

- Messages

- 674

Shaping balsa should be done with a mini wood plane, slow and carefully. Use Evercoat afterwards to fill in your low points and sand it to perfection.

Thanks for the advice! Beautiful build also! It's quite a feat to build a working airplane from scratch!

Balsa does indeed respond very well to hand tools. It planes and sands so satisfyingly that it's easy to get carried away. I think I'll still turn down the rough shape on the lathe, that way I can ensure a concentric part. But this time I'll probably leave on maybe 1/4" on the OD so I can plane and sand to final dimensions. I did notice a lot of really bad tear out when I turned the balsa in the lathe, even with a sharp tool. I want to try to minimize that tear out on the finished surface so I'll sneak up on it with planing/sanding.

Also to aid in rigidity I turned down a 1" dowel from an oak board. I'll glue that into the balsa block and hopefully it'll be stiffer for working.