-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Craftsman 6" 101.07301 tear down and rebuild thread (and some questions)

- Thread starter mattthemuppet2

- Start date

- Joined

- Sep 28, 2013

- Messages

- 4,395

hi Robert, I pulled the tape off the motor plate and it says 1/4hp/ 4.8A/ 110V, so 16AWG is in order. I'll try and scoot out from work tomorrow to get some. Nearly finished painting the motor shells, just had a bit of problem with the cold and the paint crinkling up, so I need to recoat the center section tomorrow (got a lecture to write tonight)

- Joined

- Sep 28, 2013

- Messages

- 4,395

- Joined

- Sep 28, 2013

- Messages

- 4,395

got some 16-4 from a local electrical supplies shop this afternoon, really friendly guy there helped me pick out the most suitable. The new wire is quite a bit chunkier! I'll be putting the motor back together in a bit after the kids go to bed.

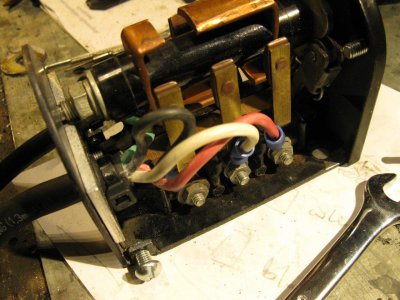

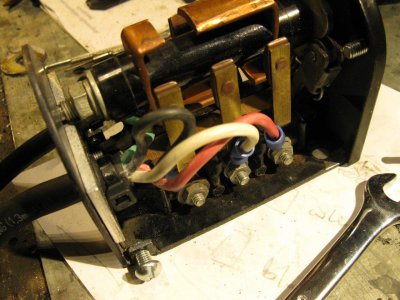

finished the chuck and the drum switch too. The chuck feels pretty tight, so we'll see how it checks out once everything's back together. I made a bolt in plate for the bottom of the drum switch so I could fit appropriately sized grommets for strain relief and to cut down on the size of spider that can get in there.

View media item 94522View media item 94523View media item 94525View media item 94526

finished the chuck and the drum switch too. The chuck feels pretty tight, so we'll see how it checks out once everything's back together. I made a bolt in plate for the bottom of the drum switch so I could fit appropriately sized grommets for strain relief and to cut down on the size of spider that can get in there.

View media item 94522View media item 94523View media item 94525View media item 94526

- Joined

- Sep 28, 2013

- Messages

- 4,395

sorry, getting the hang of the new forum functions!

- Joined

- Sep 28, 2013

- Messages

- 4,395

Thanks Jim! It's a jewel in the rough that's for sure. Wait until you see the motor

- Joined

- Sep 28, 2013

- Messages

- 4,395

it spins! Finally got the motor put back together and wired up last night. Worked a beaut, really quiet and smooth. The pulley might need to be bored and sleeved as it has a bit of wobble in it, but we'll see how much of an issue that is first, plenty of other things to do

next up is the tailstock, then apron, then leadscrew, headstock and bed. Just not tonight

next up is the tailstock, then apron, then leadscrew, headstock and bed. Just not tonight

- Joined

- Sep 28, 2013

- Messages

- 4,395

not a huge amount of progress as work is taking up all my time and I have a job interview to prepare for next week. But, as a way of keeping my sanity, I've been doing little bits'n'pieces every hour or so of work. Got my new power supply set up and it's the bomb - way more effective electrolysis than before. Tail stock and steady rest have been derusted/ degunked down to bare metal and primed, most of the hardware has been cleaned up and I'll start with the top coats tomorrow when it warms up a bit - pics to come! It's funny, I originally promised myself that I'd only clean and oil this lathe as I have little spare time (and lots of things I want to do with this!) but I'm really enjoying the whole caboodle.

Jim - I found out why that ring was welded/ brazed onto the steady. One of the finger slots had a crack running the length of one side at the bottom (dropped perhaps?) so although the steady wasn't cracked all the way through, presumably whoever fixed it brazed the crack and added the ring for good measure.

Jim - I found out why that ring was welded/ brazed onto the steady. One of the finger slots had a crack running the length of one side at the bottom (dropped perhaps?) so although the steady wasn't cracked all the way through, presumably whoever fixed it brazed the crack and added the ring for good measure.

- Joined

- Feb 2, 2013

- Messages

- 3,960

Looking good Matt!!!