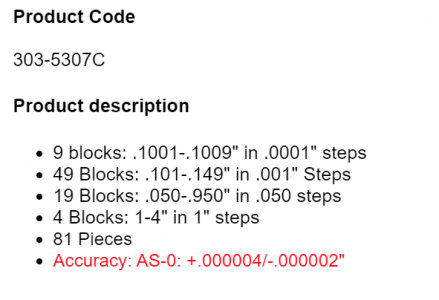

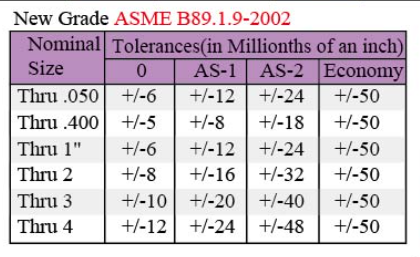

Excellent example. You cannot qualify a measuring tool to .0001 using gage blocks that have a +-.00005" tolerance. Although I think Jrout is right that it's only 11 microinches. Stacking all the tolerances would be out 22 microinches, however using the squareroot of the sum of the squares that brings it down to 11 microinches since some of the tolerances should average out as opposed to the all being at the max and stacking.My Mitutoyo digital mic, which is the most accurate and precise instrument I have, only resolves to 50 microinches. A micron is about 39 microinches. Let’s say you stack four gauge blocks, two in the 6 micron tolerance range and two in the 5 micron region. These tolerances don’t add linearly but add up as the square root of the sum of the squares. So the expected tolerance of the stack would be 11 microns, or 430 microinches, or about 4 tenths. This is easily discernable.

Only you know if this is acceptable.

Using the 4:1 rule. That should allow the blocks to calibrate to .000044" (~50 millionths) in that size range. Which is what a mitutoyo digital mic reads out to.

Last edited: