I'm glad I could help someone, I'm no teacher and all the software conflicts to get the microphone, camera, and screen capture to all work together was a bugger.

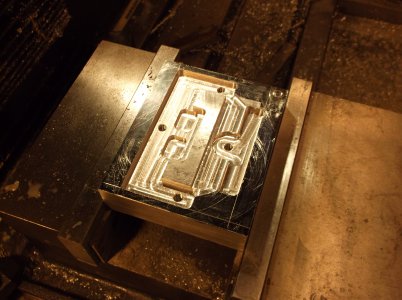

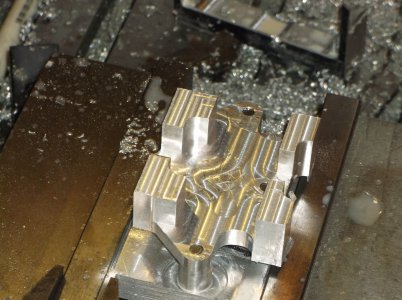

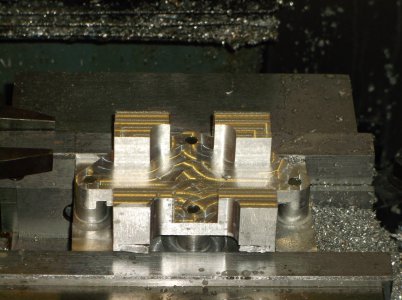

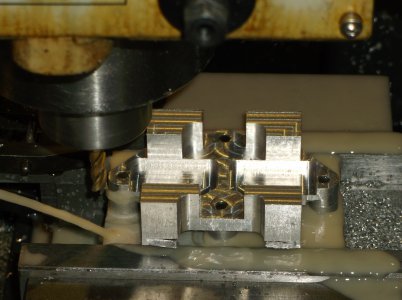

yesterday I was in the shop getting some ideas on the fixture to hold the stock while machining.

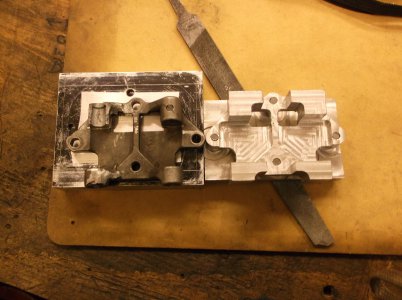

I have decided to machine the bottom first then bolt the stock to the fixture, that way I wont have to remove it again until it is finished. It's looking like the machining order will be bottom, top, front then back. the fixture will be machined out of a solid piece instead of a plate and spacers but on the final machining of the back section it will machine off one of the leg supports. not a problem since it's not intended to be a production run just one part. I have decided to do a little cam work in d2nc then do a little machining so I can get out in the shop more. I have a fair internet connection in there now so i'll start filming from there.

it was a good excuse to clean up the shop anyway.

steve

D2NC.com has videos showing how to use all the features, the first ones are about how to use the drawing part of d2nc, I have never used it . the later ones go into importing a dxf and all the tools and options. there are a lot more options than I'm getting into in these videos including nesting, 4th axis, text with any font, movable tabs and a lot more. I'm not a part of d2nc I just cant believe what a great tool it is for about $80. my total investment in the cad/cam software's I use the most is $80. I have used and purchased a few others but I keep coming back to emachineshop and d2nc. now if I could just get my head around something easier to use for the cnc lathes.

steve