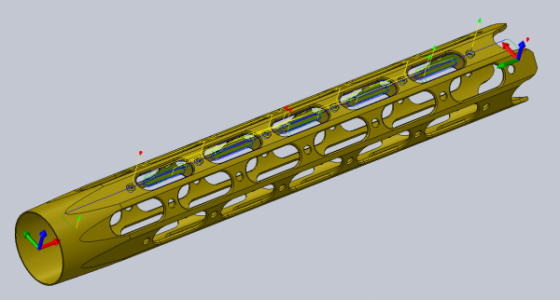

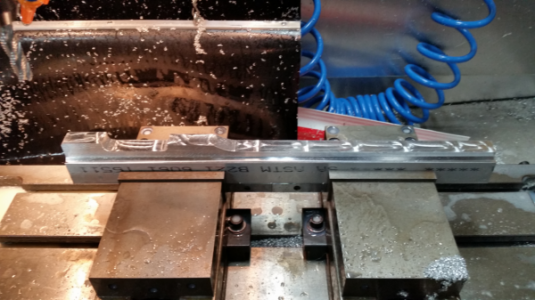

Things went pretty well today. I learned a few things but overall I'm happy with the result.

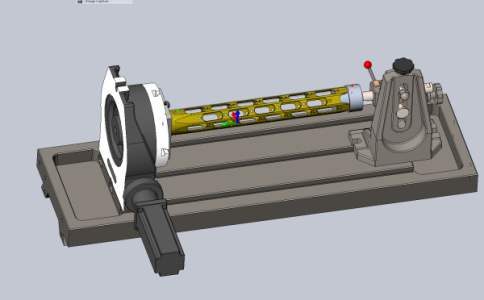

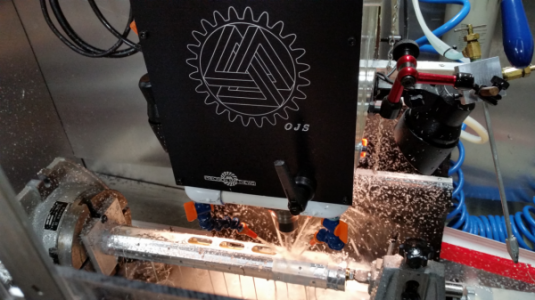

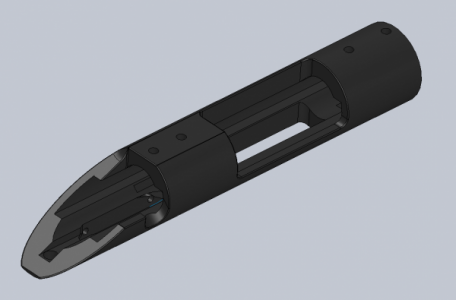

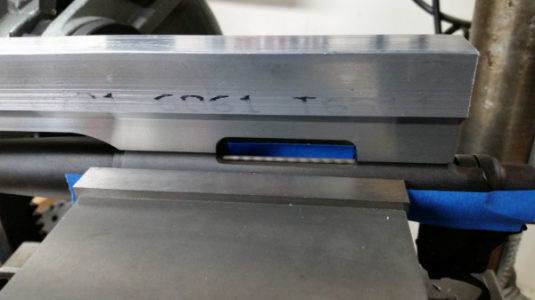

First op was to cut the flats on eight sides. I'm glad I modeled the fixture in solidworks. I caught a cut interference with the button head cap screws that hold the fixture to the rotary axis. I was able to change the lead out to avoid it.

View attachment 142418

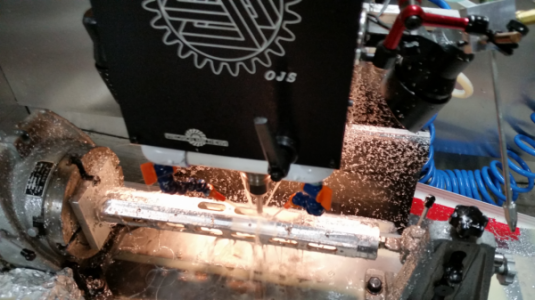

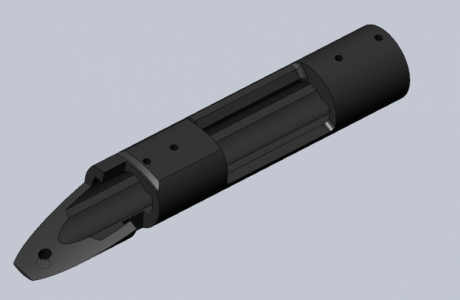

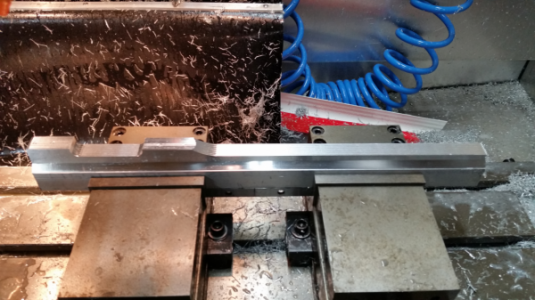

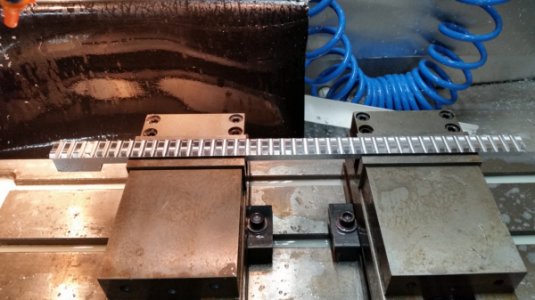

Next was drilling the holes.

View attachment 142419

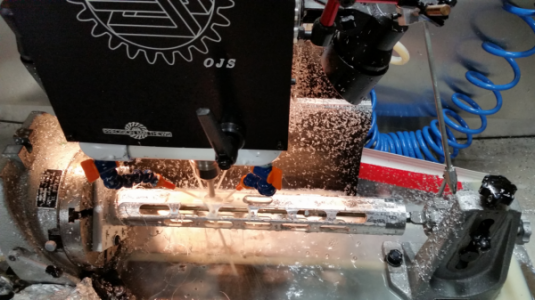

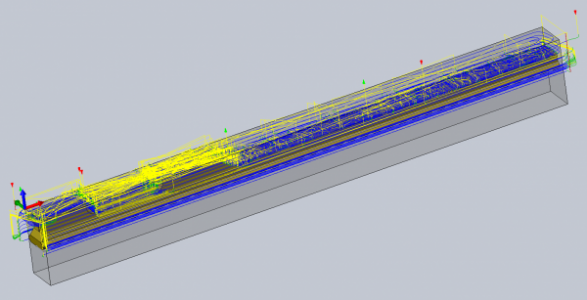

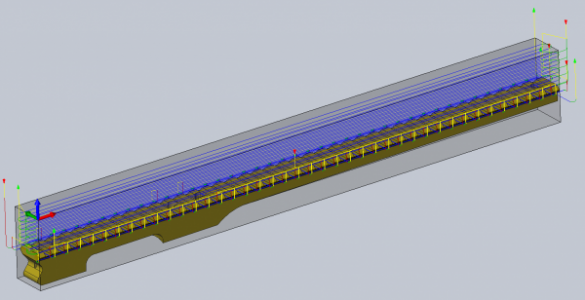

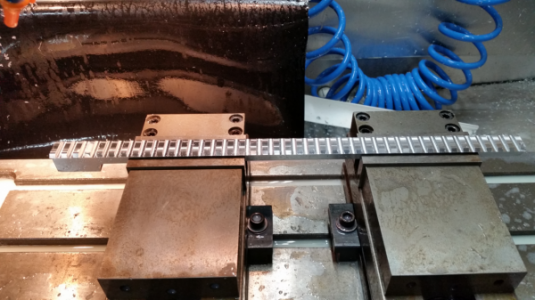

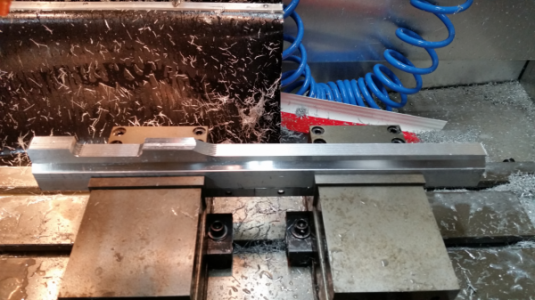

Next is milling the slots.

View attachment 142420 View attachment 142421 View attachment 142422 View attachment 142423

Next is the chamfer on the slots. I was getting some chatter out at the tail-stock end. At first I thought it might be because as the slots were being cut the torsional rigidity was being compromised allowing that end to twist a little. Turned out the tail-stock was not tight. Oversight on my part.

View attachment 142424 View attachment 142425 View attachment 142426

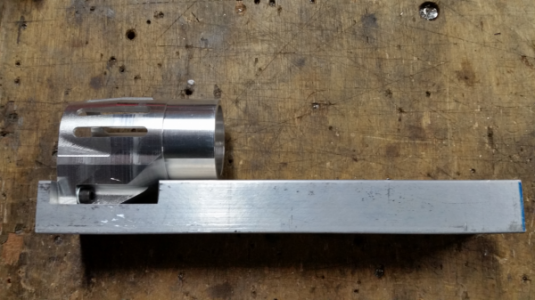

Final op on the 4th axis is the front contour. I couldn't figure out how to do this tool path in HSMWorks so I used Aspire for the CAM. I added some additional screws to keep the end plug from rotating in the part during cutting.

View attachment 142427

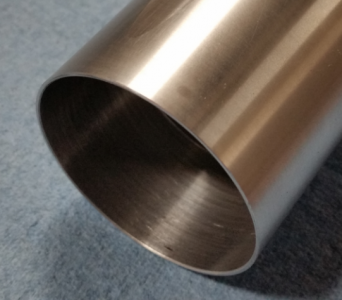

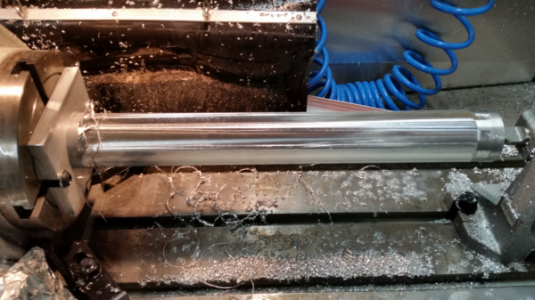

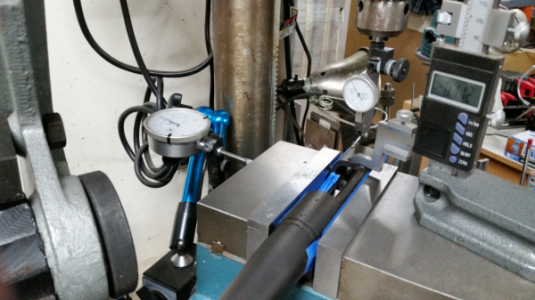

Off to the lathe to turn the final OD and rear taper.

View attachment 142428 View attachment 142429

Completed part ready for final deburing.

View attachment 142430 View attachment 142431 View attachment 142432