- Joined

- Dec 3, 2013

- Messages

- 1,849

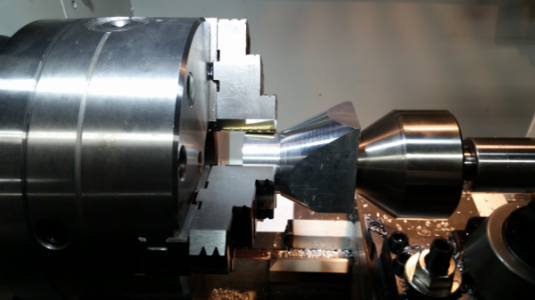

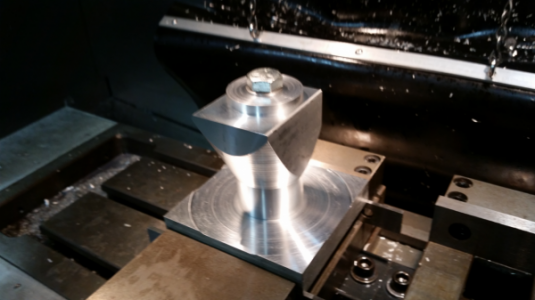

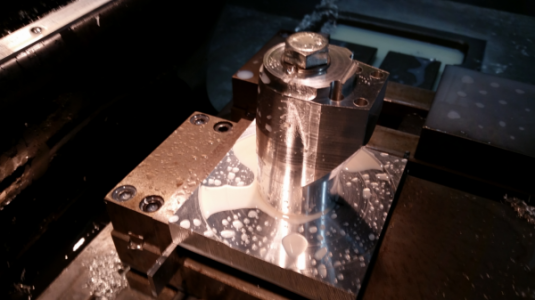

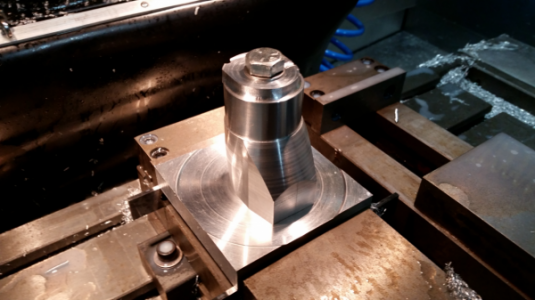

The receiver stock is done. I had a few anomalies with some of the tool paths where the cutter skipped over some of the details during the 3D passes. It's kind of strange where most finished dimensions are within a few thou which I think is good considering there were tool paths on 5 of six sides but there are a few that were 10 to 20 thou off, all on the 3D tool paths. Part of the path would be perfect and another part would be slightly off. I have some backlash in the system I need to take care of and it really shows in some of the blend lines.

I also discovered the 3D CAD model of the receiver I got from a friend wasn't modeled correctly. The important dimensions were there but the taper at the rear of the receiver is way off and the slot for the bolt handle is not deep enough. I'm going to try and recut the taper. Hopefully it comes out okay. I'm still trying to figure out how to use extra long end mills without leaving chatter marks.

I also discovered the 3D CAD model of the receiver I got from a friend wasn't modeled correctly. The important dimensions were there but the taper at the rear of the receiver is way off and the slot for the bolt handle is not deep enough. I'm going to try and recut the taper. Hopefully it comes out okay. I'm still trying to figure out how to use extra long end mills without leaving chatter marks.