Hi, I am new to machining generally, having started out with watchmaking lathes. I recently acquired a well used but more or less complete Atlas 6" Mk 2 lathe.

My main concern is the spindle does not turn very freely. A am assuming this is due to grotty bearings and was expecting to replace them in this process. I am not sure what a really free spindle in one of these feels like, but given how light it is, I would imagine it would spin somewhat freely as opposed to requiring firm pressure to move it. If this amount of resistance is not an issue, I'd be tempted to forego any more messing with it... it certainly moves under power.

I have managed to disassemble the majority of it, but there is one area that is stuck and I am unable to free it.

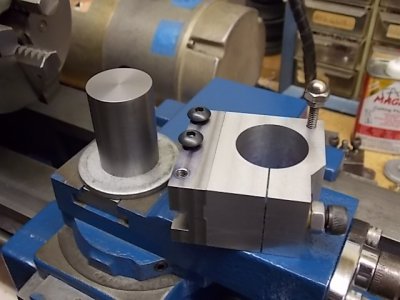

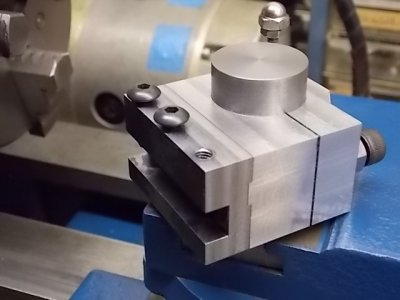

The innermost gear on the spindle shaft (that engages with the back gear mechanism) and the spacing/clamping collar to the left of it are not moving. I took out the grub screws in the collar, and it has 1-2mm of rotational play and along the shaft, but will not slide off. I understand there is a Woodruf key for the gear, but it does not engage on the collar, as I have enough clearance to see the shaft and have cleaned up the old grease. I put long screws in the collar's grub screw holes and tried applying a bit more force/torque, but it only rocks a bit and slides axially even less. If the grub screws bit into the spindle, like they seem to on the left end, then it might have pushed up a bur that is limiting movement, but this seems like more than something like that. Even if it does, this shouldn't keep the ring from sliding off the shaft. I tried blocking it up and beating the spindle out (relatively gently) from the back with a deadblow hammer and it did nothing, same play, no movement in the spindle or front bearing. If I were to use a jack to press out the spindle at this point would the gear and ring get forced off, or would I just break everything? I was also thinking a gear puller would be useful, but I am worried about the zamak cast gears, as I am told they are fragile.

Having watched a couple of other atlas bearing replacements (for other lathes) on youtube, I am a little surprised at how firmly this seems to be put together... I am assuming I will need a press of some sort to manage this? I was thinking a bottle jack?

Anyhow, if anyone has experience tearing down and putting new bearings in one of these, or more generally, I would appreciate hearing about it.

Thanks!

My main concern is the spindle does not turn very freely. A am assuming this is due to grotty bearings and was expecting to replace them in this process. I am not sure what a really free spindle in one of these feels like, but given how light it is, I would imagine it would spin somewhat freely as opposed to requiring firm pressure to move it. If this amount of resistance is not an issue, I'd be tempted to forego any more messing with it... it certainly moves under power.

I have managed to disassemble the majority of it, but there is one area that is stuck and I am unable to free it.

The innermost gear on the spindle shaft (that engages with the back gear mechanism) and the spacing/clamping collar to the left of it are not moving. I took out the grub screws in the collar, and it has 1-2mm of rotational play and along the shaft, but will not slide off. I understand there is a Woodruf key for the gear, but it does not engage on the collar, as I have enough clearance to see the shaft and have cleaned up the old grease. I put long screws in the collar's grub screw holes and tried applying a bit more force/torque, but it only rocks a bit and slides axially even less. If the grub screws bit into the spindle, like they seem to on the left end, then it might have pushed up a bur that is limiting movement, but this seems like more than something like that. Even if it does, this shouldn't keep the ring from sliding off the shaft. I tried blocking it up and beating the spindle out (relatively gently) from the back with a deadblow hammer and it did nothing, same play, no movement in the spindle or front bearing. If I were to use a jack to press out the spindle at this point would the gear and ring get forced off, or would I just break everything? I was also thinking a gear puller would be useful, but I am worried about the zamak cast gears, as I am told they are fragile.

Having watched a couple of other atlas bearing replacements (for other lathes) on youtube, I am a little surprised at how firmly this seems to be put together... I am assuming I will need a press of some sort to manage this? I was thinking a bottle jack?

Anyhow, if anyone has experience tearing down and putting new bearings in one of these, or more generally, I would appreciate hearing about it.

Thanks!