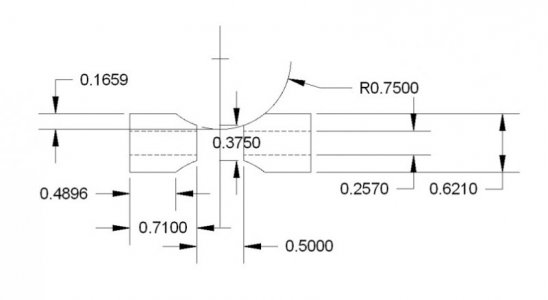

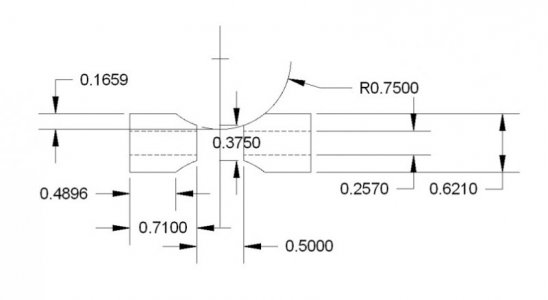

I redid the drawing with a half inch gap. It looks better, as there is now a gap of .2892 between the two arcs, so there's about .015 clearance from the overarm. Please excuse the ridiculous numbers of decimals. I need to carry them to make the fractions come out right. I need to make one of these once I get my arbor support made. I have not shown the square recess.

To make it, I think what I will do is make a part that is as long as the two of them, plus the half inch space in the middle. I have a 1.5" diameter horizontal milling cutter, so I'll put that on an arbor in my vertical mill and pass down both sides to the right depth. Then I'll cut 1/2" out of the middle.

Now what to use to make it? Wikipedia says Zamak 3 is "the defacto standard" for Zamak alloys, and has a yield strength of 30,200 psi. The other Zamaks range from 29,000 to 52,000 psi. These seem pretty soft, so I'd guess it's Zamak 3. Again, Wikipedia says "T6 temper 6061 has ... yield strength of at least 35,000 psi (241 MPa). More typical values are ... 40,000 psi (275 MPa), respectively. Sounds like it's about right.