I have a need for a very custom insole myself. Birth defect, two surgeries when I was a kid. I employed the podiatrist and his prosthetics lab years ago, and it was a waste of time and money. I do not have the rigidity requirement you do, but I have made plaster casts and learned how to cast closed cell foam. The change in comfort was life-altering.All finished, there was a lot of sanding with this. It turns out that it is as important for it to fit the shoe's contours as well as the shape of my foot. I got it thinned out pretty good. I am going to try it and possibly thin it out a little more if I think it needs it. Don't want to make it too thin. There are no hot spots and it keeps the front of my foot flat. The best part is that I don't have to wear that godforsaken cast anymore. View attachment 369438View attachment 369439View attachment 369440View attachment 369441View attachment 369442

The shape of it holds it in place.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2021 POTD Thread Archive

- Thread starter Gaffer

- Start date

Foot problems really suck. I have had surgery for planter fasciitis on both feet. The last thing I needed was more foot problems from an injury.I have a need for a very custom insole myself. Birth defect, two surgeries when I was a kid. I employed the podiatrist and his prosthetics lab years ago, and it was a waste of time and money. I do not have the rigidity requirement you do, but I have made plaster casts and learned how to cast closed cell foam. The change in comfort was life-altering.

I'll try the carbon fiber insert when it comes in. Hopefully it will not be too noticeable and help my foot heal. If it doesn't work out, you may be getting a pm from me.

Feel free to contact me anytime. For builders/makers/fixers like us, it was an interesting project.Foot problems really suck. I have had surgery for planter fasciitis on both feet. The last thing I needed was more foot problems from an injury.

I'll try the carbon fiber insert when it comes in. Hopefully it will not be too noticeable and help my foot heal. If it doesn't work out, you may be getting a pm from me.

NO ONE can understand the fit like the guy that has to live with it.....

Was definitely not a POTD, but "woodfest 2021" is officially done. We heat a 4000+ sf home with propane and supplement with firewood. We burn around 7 full cords a year. I'm really looking forward to next year when I'm retired. Instead of dedicating weekends for cutting, splitting and stacking, I'll have 7 days a week to spread the work over. Plus, we recently installed a geothermal system though I suspect we'll potentially just be trading the cost of one energy source (propane) for another (electricity). The air conditioning cycle makes sense to me, but the jury is still out for the heating cycle (just don't understand how you get energy out of 55 F degree water).

Bruce

Little over 8 full cords in the pole barn

About a full cord in the garage. For those who look closely at pictures, the fence in the foreground is where we raise meat chickens in the spring. In another month my POTD will be whacking 2 or 3 a night. Sorry if I'm offending any PETA members, but I like protein even if it had a face.

About 1 1/2 full cord stored outside the walk-out basement

Bruce

Little over 8 full cords in the pole barn

About a full cord in the garage. For those who look closely at pictures, the fence in the foreground is where we raise meat chickens in the spring. In another month my POTD will be whacking 2 or 3 a night. Sorry if I'm offending any PETA members, but I like protein even if it had a face.

About 1 1/2 full cord stored outside the walk-out basement

My back hurts just looking at the pictures of all of that cutting and splitting.woodfest 2021

Wow, that's a lot of wood! I heat 1850 sq. ft. exclusively with wood and burn less than 5 cords. I try to stay 3 years ahead, so there's always 10-15 cords stacked out back. Just finished filling the shed for next winter. Having trouble getting motivated to start cutting.Was definitely not a POTD, but "woodfest 2021" is officially done. We heat a 4000+ sf home with propane and supplement with firewood. We burn around 7 full cords a year. I'm really looking forward to next year when I'm retired. Instead of dedicating weekends for cutting, splitting and stacking, I'll have 7 days a week to spread the work over. Plus, we recently installed a geothermal system though I suspect we'll potentially just be trading the cost of one energy source (propane) for another (electricity). The air conditioning cycle makes sense to me, but the jury is still out for the heating cycle (just don't understand how you get energy out of 55 F degree water).

Bruce

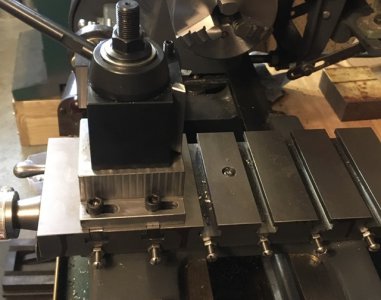

Well this iteration isn't without its own shortcomings, but I think it's better than last weeks version. Made of steel, and I lost track of my position a few times, which resulted in unequal slots. But... fully functional and unlikely to ever be replaced again. Thanks for looking!

Attachments

Wowsers! That's an incredible amount of cuttin' and splittin'!Was definitely not a POTD, but "woodfest 2021" is officially done. We heat a 4000+ sf home with propane and supplement with firewood. We burn around 7 full cords a year. I'm really looking forward to next year when I'm retired. Instead of dedicating weekends for cutting, splitting and stacking, I'll have 7 days a week to spread the work over.

It does tend to be a bit counter-intuitive. But then, I was able to heat-pump my house in Oregon when it was 20ºF (or sometimes even colder) outside! How's that for mind bending?Plus, we recently installed a geothermal system though I suspect we'll potentially just be trading the cost of one energy source (propane) for another (electricity). The air conditioning cycle makes sense to me, but the jury is still out for the heating cycle (just don't understand how you get energy out of 55 F degree water).

Anyway, your heatpump should be significantly less expensive to use than propane. I researched the economics about 20 years ago. At least at that time, the cost of propane heat was about the same as plain electric heat. Heat pumps are something like 30% more efficient than "dumb" electric heat. And unlike air sourced heat pumps, a geothermal does not periodically have to be run in "air conditioner" mode to defrost the outdoor coils - so even more efficient! While in Oregon I frequently wished I could afford the capital cost to convert to geothermal. I think you'll be pleasantly surprised this winter.

Hi John,It does tend to be a bit counter-intuitive. But then, I was able to heat-pump my house in Oregon when it was 20ºF (or sometimes even colder) outside! How's that for mind bending?

Anyway, your heatpump should be significantly less expensive to use than propane. I researched the economics about 20 years ago. At least at that time, the cost of propane heat was about the same as plain electric heat. Heat pumps are something like 30% more efficient than "dumb" electric heat. And unlike air sourced heat pumps, a geothermal does not periodically have to be run in "air conditioner" mode to defrost the outdoor coils - so even more efficient! While in Oregon I frequently wished I could afford the capital cost to convert to geothermal. I think you'll be pleasantly surprised this winter.

Good to hear. My wife was the driver for installing what's called a "well connect" system. The source of water is our well. Her motivation was helping reduce the amount of wood I cut every year. I haven't looked into how the heating cycle works, but the A/C makes perfect sense to me.

I fiddled with my old house's A/C system 35 years ago and improved the efficiency quite a bit. The cycle works off the perfect gas law of PV=nRT. When pressure goes up (compress the freon), the temperature goes up. Run the hot/compressed freon through condenser coils and run a fan to draw outside air over the coils to transfer heat to the cooler outside air. Then let the freon drop in pressure through a throttle valve and temperature drops. Run the cooled freon through another coil in the furnace plenum and remove heat from the warmer inside air by transferring it to the freon.

My set up at the time was to cycle on a lawn sprinkler valve when the A/C kicked on. I let the condenser fan run as usual, the sprinkler valve supplied a soaker hose setting inside the condenser above the coils. Cold water drizzled onto the hot lines which cooled them much more than the hot outside air. I had to put a switch in the A-frame to sense ice build up as it could make a brick. When ice built up to the point it tripped the contact switch, the water system kicked off so it ran on its normal cycle and melted the ice. It cut my electric bills by over half.

Our well connect cooling cycle works the same way. Ours is an open-loop system and dumps the water 100 feet from our house. Coincidentally, it's right on the edge of our woods and a feed plot. Might be deer hunting from the house this year.

Bruce

Tool storage from scrap and bonus buys.

So we picked up a bunch of cutters and taps from the pawn shop and in storing the taps got fed up...

We had a capacitor store case that has steel drawers with now plastic boxes for the taps and made nice labels but not cutting it.

We had multi batches of drill bits picked up at estate sales in assorted hardware cabinets, not cutting it.

Seen the huot cabinets for years and hoping to find at a sale and no good.

Gee, stimulus bucks...what to do...

Amazon had the 3 pack, fractional, number and letter on sale and the tap box for small taps also on sale.

Found a supplier in Fresno who had the line on sale and the box for large taps was better than Amazon so we got it.

5 total, then the cart states only stack 3 high, we looked around the shop and too much clutter, no place to put them.

What to do...

In the scrap pile we had a radio rack a and some rack mount drawers.

We had some extra rack top bars that we modified to hold top and bottom box in place.

Some clever screw locations ad stainless steel strapping hold boxes well, blind tapped for rear mounted screws through existing equipment screw holes.

A trip to the scrap yard found some aluminum strips that we made for side trim.

Still need to go to restore as they have screw operated strap clamps ( hose clamps) that are maybe 3 feet long to go around the stack to keep them straight.

Rack is on casters so it rolls to where it is needed.

The drawers hold machine screws and project parts.

The mill and lathe cutters now can go in the capacitor box...

Sent from my SAMSUNG-SM-G930A using Tapatalk

So we picked up a bunch of cutters and taps from the pawn shop and in storing the taps got fed up...

We had a capacitor store case that has steel drawers with now plastic boxes for the taps and made nice labels but not cutting it.

We had multi batches of drill bits picked up at estate sales in assorted hardware cabinets, not cutting it.

Seen the huot cabinets for years and hoping to find at a sale and no good.

Gee, stimulus bucks...what to do...

Amazon had the 3 pack, fractional, number and letter on sale and the tap box for small taps also on sale.

Found a supplier in Fresno who had the line on sale and the box for large taps was better than Amazon so we got it.

5 total, then the cart states only stack 3 high, we looked around the shop and too much clutter, no place to put them.

What to do...

In the scrap pile we had a radio rack a and some rack mount drawers.

We had some extra rack top bars that we modified to hold top and bottom box in place.

Some clever screw locations ad stainless steel strapping hold boxes well, blind tapped for rear mounted screws through existing equipment screw holes.

A trip to the scrap yard found some aluminum strips that we made for side trim.

Still need to go to restore as they have screw operated strap clamps ( hose clamps) that are maybe 3 feet long to go around the stack to keep them straight.

Rack is on casters so it rolls to where it is needed.

The drawers hold machine screws and project parts.

The mill and lathe cutters now can go in the capacitor box...

Sent from my SAMSUNG-SM-G930A using Tapatalk