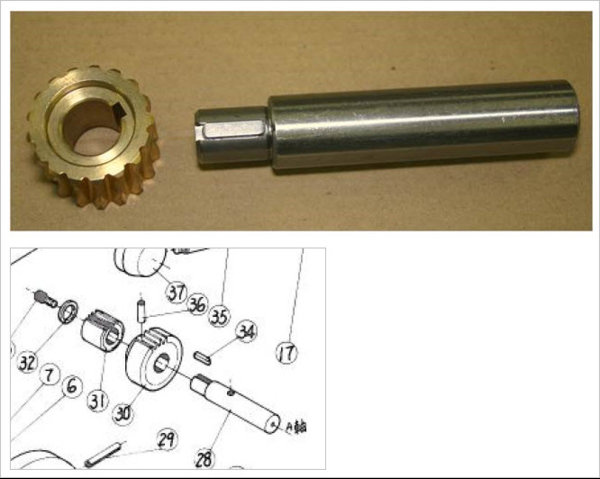

I didn't elaborate on this aspect much, but maybe worth mentioning with a pic. Yet another potential fitting tweak you might encounter. The brass gear that engages the steel worm gear is mounted on a shaft with a key. The steel worm gear drives the brass gear which drives the internal carriage gear train to traverse the carriage. That's the power feed mode.

The brass gear can only go on one way. It has a depression on the outboard side for a washer & cap screw. But what I had not appreciated until I chased down my particular misalignment issue step by step is that the brass gear can actually be set improperly. I assumed it should butt up against the shaft shoulder (and I suspect that's how its supposed to be). But for whatever reason, probably related to my apron not being positioned correctly on the carriage top (but nothing I can do about it) its possible to have a perfectly concentric PF rod running within correctly set up bushing block, but if this brass gear is off center even a slight amount, that will make for binding. Because the gear has kind of a saddle profile, any in/out deviation really aggravates this misalignment. Hope this makes sense. Anyway, that's why I ended up having to make a brass shim washer between the apron casting & brass gear to establish this distance because if I tightened the gear end cap fully, the gear slid it down the key & was out of alignment.

Now whether I'm correcting 'factory' issues or this is an inherent design thing, I can only guess.

The brass gear can only go on one way. It has a depression on the outboard side for a washer & cap screw. But what I had not appreciated until I chased down my particular misalignment issue step by step is that the brass gear can actually be set improperly. I assumed it should butt up against the shaft shoulder (and I suspect that's how its supposed to be). But for whatever reason, probably related to my apron not being positioned correctly on the carriage top (but nothing I can do about it) its possible to have a perfectly concentric PF rod running within correctly set up bushing block, but if this brass gear is off center even a slight amount, that will make for binding. Because the gear has kind of a saddle profile, any in/out deviation really aggravates this misalignment. Hope this makes sense. Anyway, that's why I ended up having to make a brass shim washer between the apron casting & brass gear to establish this distance because if I tightened the gear end cap fully, the gear slid it down the key & was out of alignment.

Now whether I'm correcting 'factory' issues or this is an inherent design thing, I can only guess.