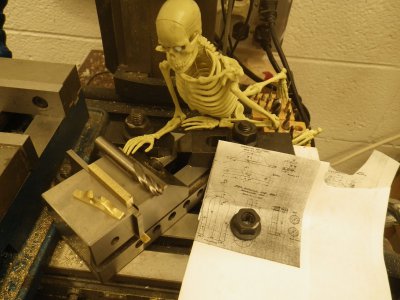

another fitting almost done,, rigged a small vise because I didn't want to reset my bigger mill vise, the ball end mills got me close to most of the curves, round and small flat files to shape it up,, a little force to get the arc of the stern rail.. now to make it's mirror image..

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

1/6th scale 1890's 30ft navy steam cutter (live steam)

- Thread starter tghsmith

- Start date