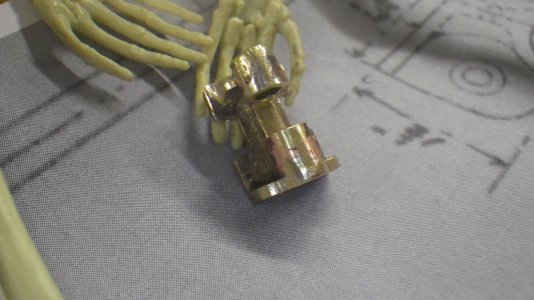

did a test run making one part to see if it could be done with silver soldering parts together,, it worked, now to set a small production line and make the 16 needed,, these are the bases for the canopy,, they also will hold the deck and coming together (plans are to have the deck and coming lift off as on piece to access internals)

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

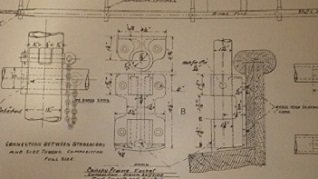

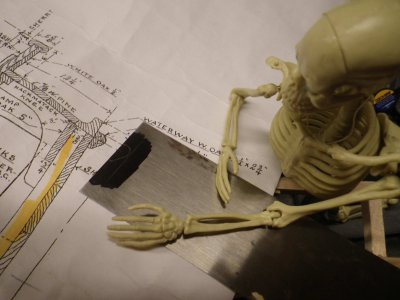

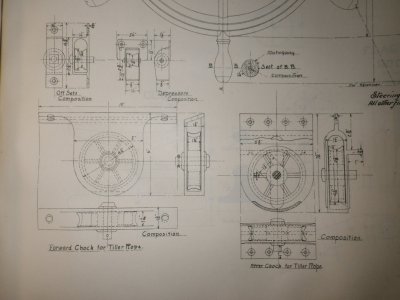

1/6th scale 1890's 30ft navy steam cutter (live steam)

- Thread starter tghsmith

- Start date