Other kind of atomic! They use a Caesium vapour and pump it with the atoms' ionisation energy/frequency, which is re-emitted when it returns to neutral - it's incredibly stable and a single frequency which is then counted down to once-a-second.

The Best Clocks in use are accurate to about a second in 158 million years, the next generation are getting difficult to measure, as they're in the one second in the lifetime-of-the-universe bracket...

I just distribute the time from 'em, accurate to a ten-millionth of a second everywhere it reaches, the easy bit.

Dave H. (the other one)

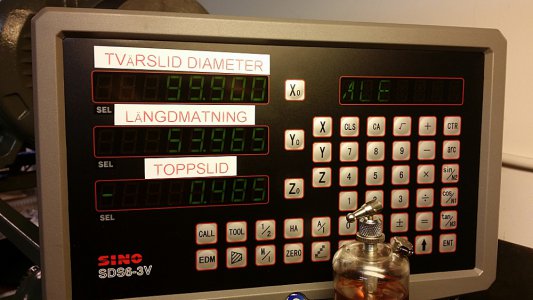

Dave, that is absolutely fascinating! And here I thought that working to .0001'' was accurate (or precise?).

Mike

I may not even follow the rules but it is how I want it.

I may not even follow the rules but it is how I want it.