- Joined

- May 3, 2017

- Messages

- 1,997

Hello, All.

I have received some very helpful responses from several of you on an older lathe I acquired similar to a Jet 1024 (Kin Shin Model KS3.5FK, 1976 model). Thanks.

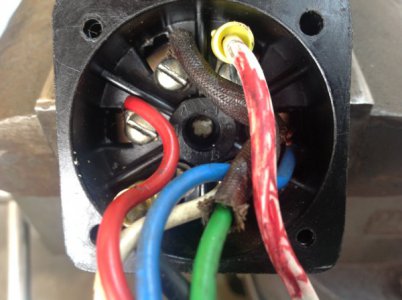

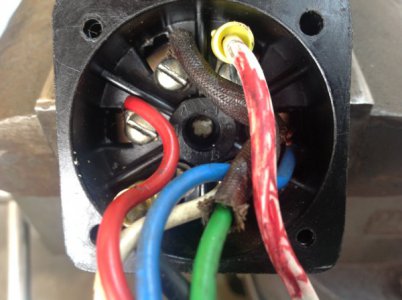

I'm down to (hopefully) one more issue before this machine is operational. I bought a new Leeson motor that I have wired for 220. The machine's original SUPPLY or IN cable was cut too short to use. It had three wires: red/black/green, which I have replaced with one that has white/black/green (you'll notice in the picture I colored the white with a red sharpie so that the three colors match the original). The red and black are wired into the switch and the green is grounded to the machine.

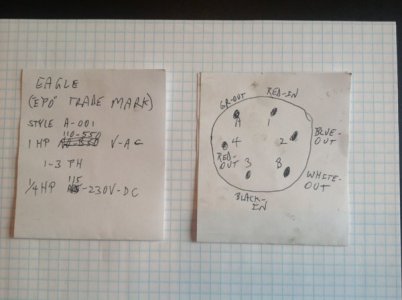

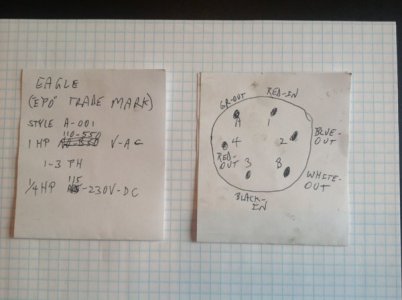

I am still using the original SWITCH or OUT bundle of four wires: red/white/blue/green - all of which are unchanged from their original positions in the switch. Below are some pictures of all this, including a photo of my handwritten info contained on the face of the switch and the exact wiring pattern before any changes (you can't really tell from the photo, but the circle of terminals are stamped in the plastic as A-1-2-B-3-4, reading clockwise).

I'm certain the motor works correctly because I first wired it directly to the SUPPLY/IN line - it hums like a sewing machine. However, when I wire into the switch then through the SWITCH/OUT line to the motor, it kicks the breaker. I have not changed any wiring in the switch other than exactly matching the IN wires.

I assumed the old OUT 'red' and 'black' to be the live lines, and the 'green' to be ground. That's how I wired them to the motor. Don't know if I'm doing something wrong or if the OUT wiring somehow got crossed before I got the machine.

Anybody have any familiarity with this issue and/or this switch in particular?

Thanks,

Terry

I have received some very helpful responses from several of you on an older lathe I acquired similar to a Jet 1024 (Kin Shin Model KS3.5FK, 1976 model). Thanks.

I'm down to (hopefully) one more issue before this machine is operational. I bought a new Leeson motor that I have wired for 220. The machine's original SUPPLY or IN cable was cut too short to use. It had three wires: red/black/green, which I have replaced with one that has white/black/green (you'll notice in the picture I colored the white with a red sharpie so that the three colors match the original). The red and black are wired into the switch and the green is grounded to the machine.

I am still using the original SWITCH or OUT bundle of four wires: red/white/blue/green - all of which are unchanged from their original positions in the switch. Below are some pictures of all this, including a photo of my handwritten info contained on the face of the switch and the exact wiring pattern before any changes (you can't really tell from the photo, but the circle of terminals are stamped in the plastic as A-1-2-B-3-4, reading clockwise).

I'm certain the motor works correctly because I first wired it directly to the SUPPLY/IN line - it hums like a sewing machine. However, when I wire into the switch then through the SWITCH/OUT line to the motor, it kicks the breaker. I have not changed any wiring in the switch other than exactly matching the IN wires.

I assumed the old OUT 'red' and 'black' to be the live lines, and the 'green' to be ground. That's how I wired them to the motor. Don't know if I'm doing something wrong or if the OUT wiring somehow got crossed before I got the machine.

Anybody have any familiarity with this issue and/or this switch in particular?

Thanks,

Terry