-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Will this work for parallels?

- Thread starter tonydi

- Start date

- Joined

- Nov 27, 2012

- Messages

- 7,855

My milling machine vises do not have that groove, but my drill press vises do....

Milling vises that have a fixed jaw that can be unbolted won't need that relief. Vises that have a fixed jaw that is one piece with the base, like the tool makers vise pictured above, will need that relief in order for grinding like extropic mentioned.

- Joined

- Jul 8, 2018

- Messages

- 880

Petroluem jelly also. Works like temporary glue for wringing parts together, even when they're not so smooth. Kinda like, well, doublestick tape.One drop of oil on each side of the flat of the parallel will make it 'stick' to the vise jaws.

Petroluem jelly also. Works like temporary glue for wringing parts together, even when they're not so smooth. Kinda like, well, doublestick tape.

Yeah, I think this or the oil would work better for me. I use some double-stick masking tape for certain jobs and it works great but often times I find myself switching parallels during the milling of a part so that would be a pain with the tape.

- Joined

- Nov 12, 2014

- Messages

- 150

How about these from LMS? https://littlemachineshop.com/products/product_view.php?ProductID=3946&category=

They also have a couple other 3" sets as well as 6"

They also have a couple other 3" sets as well as 6"

Yeah, I saw that set and thought it would at least give me the 1" I need and I'd have other smaller sizes that I don't already have. So I wouldn't consider it a $42 pair of 1" parallels.How about these from LMS? https://littlemachineshop.com/products/product_view.php?ProductID=3946&category=

They also have a couple other 3" sets as well as 6"

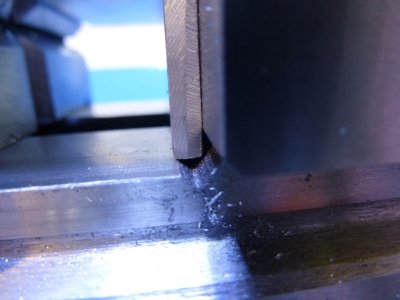

But those are 1/8" and here's what a .125" piece of stock looks like up against the fixed jaw. So little sitting on the vise itself seems sketchy to me. Right now I'm using 5/32" x 3" LMS parallels and that's the only 5/32" set they have.

- Joined

- Sep 28, 2013

- Messages

- 4,306

I have a 4" vise and as others have noted, most of the parallels will be too tall soI made most of my parallels from precision ground stock bought cheap off amazon. They're a mix of A36, O1, A2 and D something. Cut to length on the bandsaw and the left overs stuck in the stock drawer. I haven't hardened the ones that can be hardened as it's kind of neat being able to make a whoopsie (drilling typically) without screwing up the tool. A quick pass with a file and any burr on the parallel is gone. If any of them get too swiss cheesy I'll simply cut another one.

- Joined

- Mar 30, 2020

- Messages

- 32

Are the jaw pads replaceable? Rather than screw around making parallels I'd make taller jaw pads. then I would buy a cheap set of 6" parallels on Ebay or somewhere and cut them in half and use the short ones with the factory jaws and the taller ones with the tall jaws. We make special tall jaws for our Kurt for certain jobs.

Are the jaw pads replaceable?

No, if you look up at post #15 you'll seen it's all one big piece. I think all of the screwless/toolmaker's vises I've seen are like that.

@mattthemuppet2 Yes, in fact that was the idea that started this thread! I just wasn't sure that type of material was ok and if it had parallelism that was good enough. I can find precision ground steel on Amazon but nothing I'd call "cheap". I'll need to dig deeper. I also didn't see the need to harden these either.

- Joined

- Sep 28, 2013

- Messages

- 4,306

use jungle search and be patient. I think I accumulated my various bits'n'pieces over a couple of months. 5 separated orders, came to around $40 or so.

Here's one good option if 1/8" is good:

I know you stated a need for 5/32, so that might take a bit longer (though one of mine, the 1/2" one I think, is 5/32), but you'll get there eventually.

Here's one good option if 1/8" is good:

Amazon.com: D2 Tool Steel Sheet, Annealed/Precision Ground, ASTM A681, 1/8" Thickness, 3/4" Width, 18" Length: Industrial & Scientific

Amazon.com: D2 Tool Steel Sheet, Annealed/Precision Ground, ASTM A681, 1/8" Thickness, 3/4" Width, 18" Length: Industrial & Scientific

www.amazon.com

I know you stated a need for 5/32, so that might take a bit longer (though one of mine, the 1/2" one I think, is 5/32), but you'll get there eventually.