- Joined

- Feb 24, 2018

- Messages

- 1,044

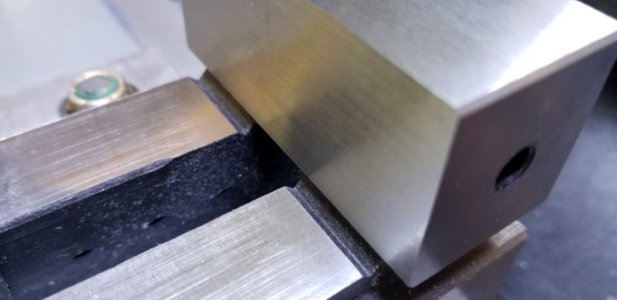

I find the subject of parallels interesting, for the Rockwell mill with a 4” mill vise, I wanted a set of 1/8” x 4” parallels. Everyone seemed to sell 3”, 6” and larger, but almost no 4”, I did find a set of 4” ultra thin wavy ones, that I bought, I still wanted the 1/8” thick. One of the vendors had a set for about $250, BangGood had a set for $80 (plus the wait) and LMS offered a set for $45, but seemed to be out of stock, continuously (finally came in and have been ordered). I found it interesting, with all of the small mills out there that 4” parallels, were so hard to find.