-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Will a Vertex HV-8 rotary table fit a PM-833T?

- Thread starter Rhizome

- Start date

- Joined

- Dec 26, 2015

- Messages

- 2,079

- Joined

- Jan 10, 2014

- Messages

- 200

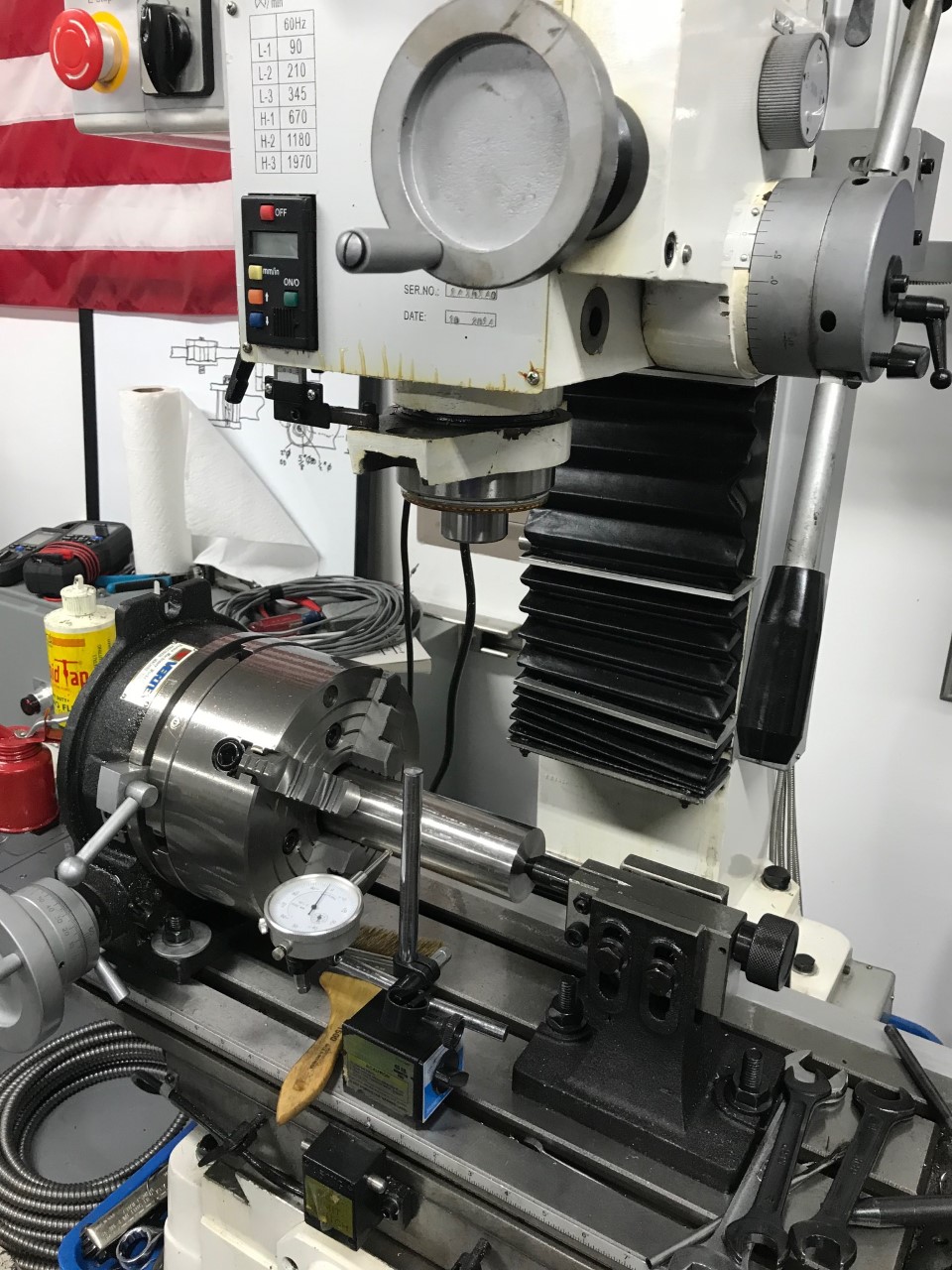

I have a Vertex 8" and a PM932. I find that the rotab is just the right size for use with this mill. My table is several years old and has 4 slots. I have seen it in the HHIP catalog as having 6 slots now. Maybe they changed it. It is made in Taiwan and is of good quality. I use a 4 jaw chuck on mine to avoid having to center a 3 jaw to the table. I find it easy enough just to dial in the work piece as one would on a lathe. I am not sure if this would be as workable with 6 slots as opposed to 4, though I suppose you could make a backplate to interface with the 6 slots on the table. Here are a couple of pics in both horizontal and vertical positions.

- Joined

- Dec 26, 2015

- Messages

- 2,079

A 4J doesn't eliminate the requirement to center the rotary table axis of rotation to the CL of the spindle when used vertically. To each their own, but I fail to see a big advantage here since one way or another that rotary table has to be aligned. That would mean two alignments are required - one for the rotary table, and a second for the part in the 4J. If the chuck is self-centering (i.e., 3J scroll) and it's centered on the rotary, the aligning the whole mess to the CL of the spindle is one operation. Am I missing something here?I have a Vertex 8" and a PM932. I find that the rotab is just the right size for use with this mill. My table is several years old and has 4 slots. I have seen it in the HHIP catalog as having 6 slots now. Maybe they changed it. It is made in Taiwan and is of good quality. I use a 4 jaw chuck on mine to avoid having to center a 3 jaw to the table. I find it easy enough just to dial in the work piece as one would on a lathe. I am not sure if this would be as workable with 6 slots as opposed to 4, though I suppose you could make a backplate to interface with the 6 slots on the table. Here are a couple of pics in both horizontal and vertical positions.

- Joined

- Jan 10, 2014

- Messages

- 200

Now that mention it, it does not really save any trouble. I have been putting the chuck on the table, centering it "close enough" and then dialing in the work piece to the table rotation. Then I would center the work piece to the spindle. For the one offs I have made it has been easy enough, but if I had a run to do, it would definitely slow things down. Great...now I have to buy another self centering chuck....

Anyone have further thoughts on the vertex rotary tables on the pm833? Is the 8" truly superior/more useful than the 6"? i am totally new, but have figured out i need to remove the cast collar on the quill of my machine and replace it with something to attach a DRO, functional depth stop, etc, as others have done..... and since i'm new (and have no lathe) the only thing i can figure is to make it with a rotary table - which i don't have.

any comments/pictures of them on the machine would be helpful.

Also if anyone knows a current good source that would be helpful. I don't want a fake, and the prices seem erratic.

Lastly, i'm not even sure what the dividing head parts would get me, but i'm sure it will ineveably be needed. Those seem even harder to find? Is there an alternative brand i should look for?

any comments/pictures of them on the machine would be helpful.

Also if anyone knows a current good source that would be helpful. I don't want a fake, and the prices seem erratic.

Lastly, i'm not even sure what the dividing head parts would get me, but i'm sure it will ineveably be needed. Those seem even harder to find? Is there an alternative brand i should look for?

I have the Vertex 8" with 3 slots and an 8" 3 jaw chuck that has through mounting. So the chuck mounting bolts go directly into the 3 slots. I had considered the 10" RT but too heavy for me. I cast an 11" plate for more area and 8 T slots. Directly clamping work to the table with only 3 slots is very limiting. Like most people I've made a device for easier centering. And another one for rounding the ends of stuff. Mounting a toolmakers vice works well for repetitive work. I put T slot blocks on the bottom that help with mounting to the mill table. I have very rarely used the table in the vertical position. I have the dividing plates but rarely use them. The vernier on the scale allows accurate rotation but it is easy to get lost after a few steps so I make a paper list. Bolt hole circles are more easily done using the DRO than a RT. I've been known to keep both the vice and the RT mounted at the same time, but sooner or later that doesn't work. I also found out that the sum of the RT & an 8" chuck is way beyond what I want to lift. I have the tail support but have rarely used it. I've run out of Z on my 9x49 knee mill few times with the RT + 8" chuck + work + tooling.

Instead of using the RT on edge (verticality) I ended up buying a BS-1 indexing head. Easier to setup & use & it came with a cheap but ±OK 6" chuck. The BS-1 will sort of work as a RT in the horizontal position but only with the chuck but maybe a table could be made for it or if you have a face plate for a lathe with a matching thread.... It eats up a lot of Z when rotated up + chuck + tooling!

Maybe if I used either of these more often I would get quicker at setting them up, maybe. At least I have gotten faster at figuring out what holes to use on the indexing plates. Every new tool is another challenge to bemastered learned.

.

Instead of using the RT on edge (verticality) I ended up buying a BS-1 indexing head. Easier to setup & use & it came with a cheap but ±OK 6" chuck. The BS-1 will sort of work as a RT in the horizontal position but only with the chuck but maybe a table could be made for it or if you have a face plate for a lathe with a matching thread.... It eats up a lot of Z when rotated up + chuck + tooling!

Maybe if I used either of these more often I would get quicker at setting them up, maybe. At least I have gotten faster at figuring out what holes to use on the indexing plates. Every new tool is another challenge to be

.

- Joined

- Nov 19, 2019

- Messages

- 72

I have the vertex 8" rotary table on the 833TV and like the size. As you figured out, there are 3 and 4 slot versions. I prefer the 4 slot version and the best price I found was from Eisen in the US. Rotagrip has good pricing on many Vertex items but the shipping for heavy stuff like a rotary table is costly.