- Joined

- Dec 20, 2012

- Messages

- 9,422

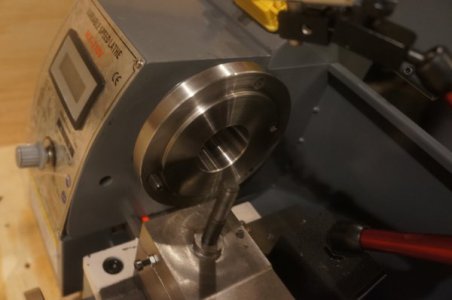

bought a chinese mini that has no measurable runout on the MT5 taper .. now to find a chuck to match!

Impressive! An 8" lathe for under $1000.00 with an MT5 spindle taper and a 1.5" spindle bore! And you say it has zero spindle run out? Even more impressive. I have to admit that I have never seen an Asian lathe with these features at this price level.

Specs like this ordinarily would require a heavy duty precision hardened and ground spindle running in Class P6 (or better) precision roller bearings; such an assembly alone would likely cost what your entire lathe cost. I'm not doubting you but I am wondering how they pulled it off.

With regard to the chuck, how does your chuck mount? If you tell me that this as a D1-camlock spindle then my jaw will officially hit the floor!