Thanks for the input so far, guys. I am interested to see if this inspires you to check your own machines, maybe it's just mine, but maybe it's an unnoticed problem. I did leave out lots of details initially, because I'm questioning all mag scales. Secondary to that is troubleshooting my machine- I can't use a scale I can't trust, that's a hard line in the concrete to cross.

You didn’t mention the readout fluttering while you were running the mill with the mag base stationary, only while you waved the mag base around. You also didn’t mention if your part was on size or not when finished. Does the readout flutter while the mag base is stationary and the table is moving? Or only when you wave the mag base around?

Tom

I squared my vise and calibrated the x and y to 1-2-3 blocks with a tenths indicator and a mag base on the head Saturday morning. I was consistently .0004 long (two steps) on y, so linear comp was applied and tested good. Removed the mag base and set up work. During work, I used a mag base for a chip shield. Part came out on size. When I was tearing down is when I saw the numbers flip like a slot machine, an obvious response to a moving magnetic field. The induction must be great enough to trip the trigger in the head, which surprises me. I don't know the effect on the display during power feed or just manual movement, it settles down when static.

What machine?

I wonder about decoupling the scales and read heads with some non ferrous or plastic would lessen this effect.

On my mini machines I have used magnets exactly twice and that was enough.

Seeing the material in the lathe chuck attract all the nearby chips and the same with the ring light on the mill was enough.

Too small/not enough mass for magnets to be used on them.

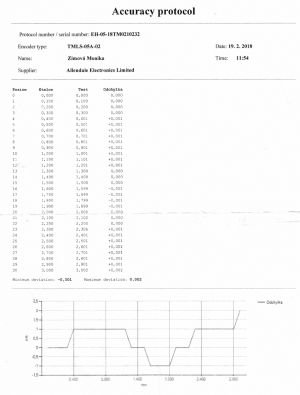

This is my Lagun FTV-3 mill, it has a 55x11" table and comes in at almost 4,000 lbs. Sh*t, I put it that way and I feel like an idiot for not going glass to begin with. Oh wait, I did order glass DC10 scales, says right here on my invoice from Ditron, but they sent me 5 mic magnetic. I've never been very excited about these, maybe that's why I never quite finished the job of installing it. The head is a Ditron D80, which I've gotten to like now that I understand it's features. If I trusted it completely, I'd like it more.

Yes, I completely agree. I had a lot of trouble with my slim mag scale at the 1um resolution, not very repeatable and wouldn't calibrate, Ditron finally admitted that it might not (!). Then they said wait, we have a new 1 micron slim scale coming, but it's a bit more. So I paid up, waited, finally they said it had shipped. What I got was the old huge optical 5um scale. And they stopped answering my emails. I still don't know what they were thinking.

The 5um Z axis mag scale seems fine, but it's a lot more shielded from stray ferrous material. Also, I developed the mag strip, and saw that the transitions are pretty widely spaced, and read somewhere they have to interpolate 1000 steps between transitions. Can this be true? If so, it's easy to see how a stray chip could easily affect the reading.

So I have zero confidence in my 1um X axis scale, but fortunately the Takisawa has a large, accurate and easy to set and read crossfeed dial.

I am very anxious to learn that somebody has developed an optical scale the same size as the slim magnetic scale. Hope that happens.

I believe that whenever two scales are read, interpolation of either scale becomes possible, with step counts and auto correction becoming possible using the reference track. I don't know so much about the implementation of such techniques in these systems, just what I can read about the technology in general on the web. I am okay with the realities of precision measurement. I have read and referenced the NIST-backed Guide to Uncertainty of Measurement in many papers, so I have realistic expectations of what I can measure and make in my shop, especially without producing some scrap to get there. On the mill, I'd be kidding myself and lying to you all if I claimed to own control over my work to any less than the .001 or .002 that these scales can measure reliably, in the wild, as installed. It's not about precision, it's about a vulnerability that could impact the worth of the numbers displayed on the screen.