- Joined

- Mar 26, 2018

- Messages

- 8,411

Well, it doesn’t.That looks great! Can't wait to see how it cuts

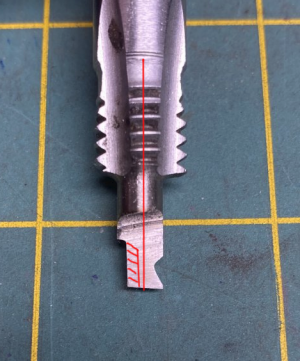

I am surprised actually. I gave it more relief on the opposite side of the dovetail.

It cuts a vertical wall. I was feeding .005” at a time, chips were coming off but no angled cut!

Back to the drawing board.

It has to be the back side cutting the vertical wall. I’ll give more relief.

Attachments

Last edited: