- Joined

- Dec 17, 2012

- Messages

- 630

if you don't mind me adding my two cents worth

Hey, I'm the one dropping in. You started the thread

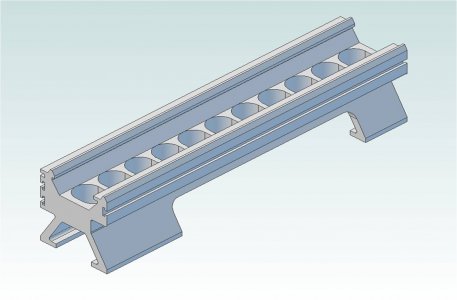

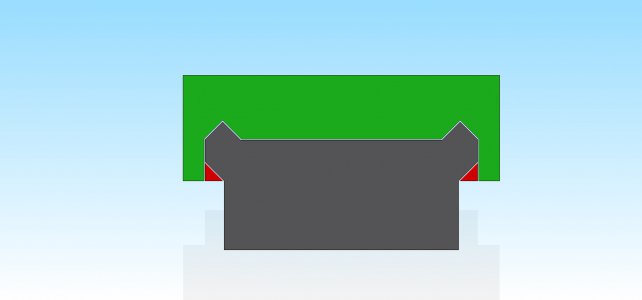

There are lots of workable configurations. There are often no real stand out *best* solutions. Boxed, dovetailed, prismatic, and tubular ways have all been successfully implemented. Each has benefits and drawbacks. Some scale better than others. Some are easier to build. Some are easier to maintain. Some use materials more efficiently. Some are cheaper to manufacture. Some are prettier.

The main controlling factors that I use in my case are cost and feasibility of construction. I don't have the capability of casting metal of that size in my home so that is out of the picture. My options for the structure are steel, aluminum, wood, cement or epoxy based aggregate, or fiber based composite (or some combination of these.) Other than wear surfaces, you could make an equivalent strength structure from any of them. For that matter, you could make a structure out of wood that would be just as strong as from cast iron. It would just take a lot more wood.