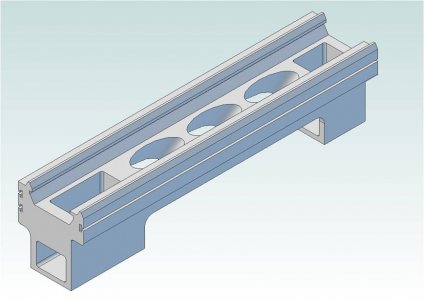

I like the idea of a t slot cross slide, wide for some milling set ups. then make it modular. so your other tooling mounts to the t slot table. you could have

a tool post for axa (or multifix) and a reverse cut off tool post for quick perations or bigger swing parts

Compound rest for manual threading

Angle plate for boring operations

Tool changer turret for cnc set ups

Oh and how about a shaper head that attaches to the top of the head stock... powered by the spindle

Same with the tailstock, the top of the tailstock slide off and a turret could be mounted for manual multi stage ops and while im at it mini gang tooling or a second spindle for really neat cnc ops.

Ball screws

d1-3 mounting for the chuck

A d1-3 to 30 taper adapter

3mt tailstock

The cool thing wouls be the modularity, so you can buy a base package, then get a turret tailstock, then on to cnc and so on.

a tool post for axa (or multifix) and a reverse cut off tool post for quick perations or bigger swing parts

Compound rest for manual threading

Angle plate for boring operations

Tool changer turret for cnc set ups

Oh and how about a shaper head that attaches to the top of the head stock... powered by the spindle

Same with the tailstock, the top of the tailstock slide off and a turret could be mounted for manual multi stage ops and while im at it mini gang tooling or a second spindle for really neat cnc ops.

Ball screws

d1-3 mounting for the chuck

A d1-3 to 30 taper adapter

3mt tailstock

The cool thing wouls be the modularity, so you can buy a base package, then get a turret tailstock, then on to cnc and so on.