-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you done in your shop lately?

- Thread starter nnam

- Start date

- Joined

- Feb 9, 2017

- Messages

- 5,250

This has happened more times than I can recall. I walk out to the shop on a nice summer Saturday. I look about the area, and reflect on the projects at hand. I try to pick one that I WANT to do. Failing that, I try to pick one I NEED to do. Failing that, I try to pick one MY WIFE needs me to do. It is at this point that I start to contemplate the meaning of life, and what it all REALLY means. Next thing I know, I am down at the figurative "fishing hole"

^This! Plus one more added complication Engineer to Stock. My current project has all the above. My SO found a tent style shed in a yard sale cheap and it served us well until the tent cover started to die. Turned out it was the same $$ to cover it with corregated roofing as the tent cover, so we roofed it. But the ends were still tent and one end finally completely died. The shed has been useful because it's 10' long and where I store my Engineering Stock that I find on CL and anyplace else I can pick it up cheap! So I'm all in and trying to make an end door in a tent shed that's like trying nail jello. I tell myself it's good mental exercise for these crusty old synapses to figure this all out so instead of complete paralysis it's more like slo mo. I also have the added pressure often needed that we might finally have some rain on the way......

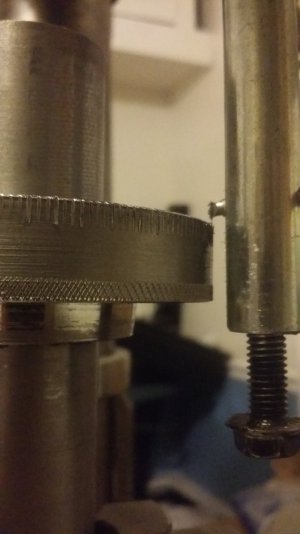

Today I made a graduated dial for a milling machine. The hard part was to find a rod that I can cut down to press fit the piece to cut in a lathe. I finally found one, but I don't have that many large pieces metal laying around.

The interrupted cutting was hard on the lathe. I wonder if someone has a solution to this, other than cutting many small straight line using a band saw before feed it to a lathe. A grinder would work very well too, but a bit noisy and dusty.

I still have the inscribing part to do.

The interrupted cutting was hard on the lathe. I wonder if someone has a solution to this, other than cutting many small straight line using a band saw before feed it to a lathe. A grinder would work very well too, but a bit noisy and dusty.

I still have the inscribing part to do.

I got the major and minor lines in. But I need to go over some lines again.

Since the division of the index plate happen to be a whole number, I much later learned that I can do it much faster by reduce the number of sector arm movement by 40 times.

Basically doing 1 full circle each time, 40 times. Then move the sector arm 1 time. Repeat that 5 times, I would get 200 small lines.

But too bad, I learned that way too late.

Since the division of the index plate happen to be a whole number, I much later learned that I can do it much faster by reduce the number of sector arm movement by 40 times.

Basically doing 1 full circle each time, 40 times. Then move the sector arm 1 time. Repeat that 5 times, I would get 200 small lines.

But too bad, I learned that way too late.

Last edited:

Today, it was raining outside, so I tried hard to tell myself to work in the garage again (the winter blue is a bit hard on me). My 3 phase rotary converter stopped working. I thought it was something to do with the capacitors. I checked every one of them with a meter, and they all looked ok (with the uf rating, not true test). So I wiggled all the connections and they seems good.

For a good measure, I went back to each connection and tighten them up good. I also happen to have a same size start capacitor, so I replaced it since it couldn't start. While I was at it, I saw the motor has 2 oil ports, so I put in some oil, and I didn't know what oil to use, so I just used way oil

After that, it started up really well and I don't know what caused it. It's likely the start capacitor.

After that, I did a boring, and I think the chips messed up the surface a bit. I used a toothbrush to clear them up, but I guess blowing air continuously on it would help. What do you when boring to clear up the chip? I am really worry about blowing air, since that push chips deep into machine area that they shouldn't be there, although I saw many people doing it.

After that, I did some interrupted cut and some chips landed on my hands, which is really hot. I ended up doing it 1 hand and cover it with a small cardboard. Works great temporarily. People must have a better solution than this, but I didn't see anything like that on youtube. Maybe they just use auto feed. I am just a bit worry about the interrupted cut, and want to back up asap if anything bad happens.

The interrupted cuts also gave me another problem. Somehow I just couldn't dial in the cut right between cuts. So I checked and the carbide insert moved. Looked closely, it was held down by a little screw. It was part of a lot I bought before. So I took it out and it turned out it was on top of another insert, which had the middle "bolted" down with a pin. The top inserts moves around because it was barely pushed down on the top. I bought the lot from a closed machine shop auction. I suppose the person doing that must knew what they were doing. Why would they stacked inserts like that? I just cut with the bottom insert only and it worked without problem.

For a good measure, I went back to each connection and tighten them up good. I also happen to have a same size start capacitor, so I replaced it since it couldn't start. While I was at it, I saw the motor has 2 oil ports, so I put in some oil, and I didn't know what oil to use, so I just used way oil

After that, it started up really well and I don't know what caused it. It's likely the start capacitor.

After that, I did a boring, and I think the chips messed up the surface a bit. I used a toothbrush to clear them up, but I guess blowing air continuously on it would help. What do you when boring to clear up the chip? I am really worry about blowing air, since that push chips deep into machine area that they shouldn't be there, although I saw many people doing it.

After that, I did some interrupted cut and some chips landed on my hands, which is really hot. I ended up doing it 1 hand and cover it with a small cardboard. Works great temporarily. People must have a better solution than this, but I didn't see anything like that on youtube. Maybe they just use auto feed. I am just a bit worry about the interrupted cut, and want to back up asap if anything bad happens.

The interrupted cuts also gave me another problem. Somehow I just couldn't dial in the cut right between cuts. So I checked and the carbide insert moved. Looked closely, it was held down by a little screw. It was part of a lot I bought before. So I took it out and it turned out it was on top of another insert, which had the middle "bolted" down with a pin. The top inserts moves around because it was barely pushed down on the top. I bought the lot from a closed machine shop auction. I suppose the person doing that must knew what they were doing. Why would they stacked inserts like that? I just cut with the bottom insert only and it worked without problem.

Last edited:

- Joined

- Jan 31, 2016

- Messages

- 11,461

Just getting started for the night , but organizing as usual . I'm going to keep only one Vidmar so I'm emptying out everything and completing sets of reamers , taps , drills , clamps , etc . This is an ongoing process and the wheels of progress turn slow , but they are turning .

- Joined

- Oct 16, 2019

- Messages

- 6,579

Just getting started for the night , but organizing as usual . I'm going to keep only one Vidmar so I'm emptying out everything and completing sets of reamers , taps , drills , clamps , etc . This is an ongoing process and the wheels of progress turn slow , but they are turning .

Feel free to shovel stuff my way!

Sent from my iPhone using Tapatalk

- Joined

- Jan 31, 2016

- Messages

- 11,461

- Joined

- Jan 31, 2016

- Messages

- 11,461

My helpers have pooped out , and I have more buckets . ( good help is hard to find ) . This will keep me busy for a while sorting thru this stuff over the cold months .  The basement is quite loaded with things and I'm finding junk as I go thru the buckets . To me it's not a big rush . I spend the time as I have it , but my helpers have been slacking lately .

The basement is quite loaded with things and I'm finding junk as I go thru the buckets . To me it's not a big rush . I spend the time as I have it , but my helpers have been slacking lately .  As you notice , no machines . They are in the garage that looks the same as this . The shop down the other place is similar . It's like I say , it'll get done one day .

As you notice , no machines . They are in the garage that looks the same as this . The shop down the other place is similar . It's like I say , it'll get done one day .

The basement is quite loaded with things and I'm finding junk as I go thru the buckets . To me it's not a big rush . I spend the time as I have it , but my helpers have been slacking lately .

The basement is quite loaded with things and I'm finding junk as I go thru the buckets . To me it's not a big rush . I spend the time as I have it , but my helpers have been slacking lately . Attachments

Last edited: