- Joined

- Sep 8, 2019

- Messages

- 4,392

Here are a bunch of pictures. Painted 45° joint, bottom half of fixture that clamps pipe (or tubing), weld test stand at 45° (6G) position as well as 2 views of horizontal (

View attachment 400389

View attachment 400390

View attachment 400392

View attachment 400391

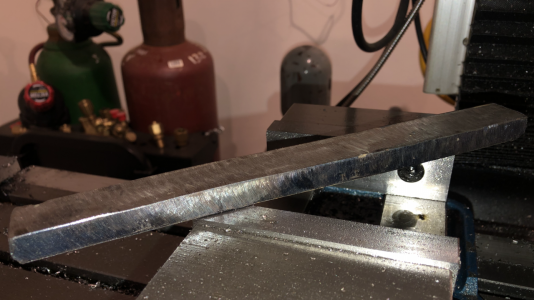

5G) position, and a 3/8” flat bar that I am going to mill.

This 3/8” flat bar was made from two 1/4” flat bars (

View attachment 400393

View attachment 400394

View attachment 400395

ded together. This 3/8” flat bar will be the top half of the fixture that holds the pipe (or tubing).

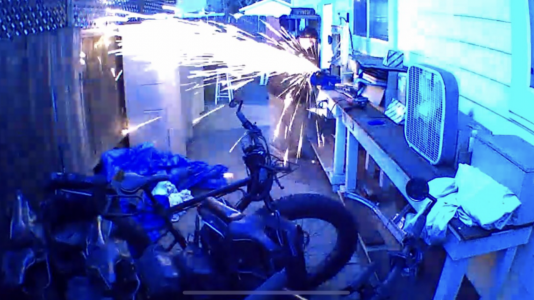

I will include a screenshot from the YouTube video that gave me the idea for this fixture. In the picture, you will see Jason Becker with the clamp that holds the pipe (or tubing).

View attachment 400388

View attachment 400389

View attachment 400390

View attachment 400392

View attachment 400391

5G) position, and a 3/8” flat bar that I am going to mill.

This 3/8” flat bar was made from two 1/4” flat bars (

View attachment 400393

View attachment 400394

View attachment 400395

ded together. This 3/8” flat bar will be the top half of the fixture that holds the pipe (or tubing).

I will include a screenshot from the YouTube video that gave me the idea for this fixture. In the picture, you will see Jason Becker with the clamp that holds the pipe (or tubing).

View attachment 400388