- Joined

- Sep 8, 2019

- Messages

- 4,392

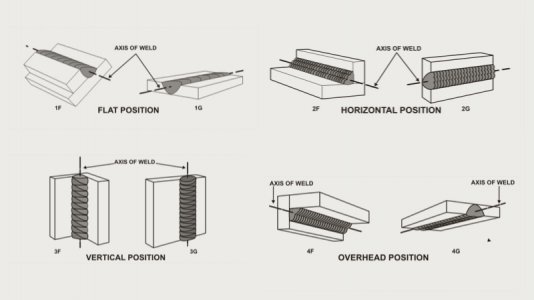

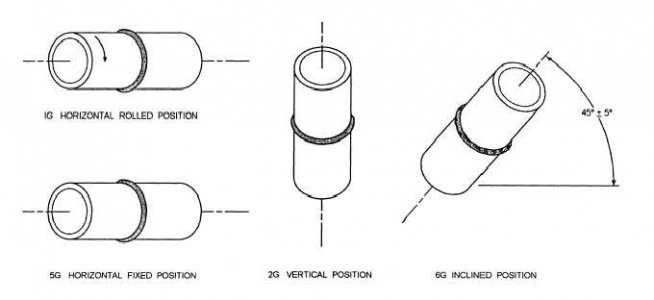

I will probably start with 1F & 1G, all carbon steel, moving on to 2F & 2G, etc. up to 4F & 4G. I am currently equipped for MIG, TIG, stick & gas. One day I will add FCAW.Really nice-looking tool! I hope to see how you get to use it.

Aaron

No motor for the rollout wheel. I will turn it by hand for stick & MIG.Eric, are you going to hook up some kind of power (chain & sprocket?) rotisserie to your 3 jaw so you can weld while it’s turning? Or did I miss it?

last place I worked we had something like that for welding augers.

What # electrodes & sizes do you have in all those canisters?

looks like you’re having fun, good for you

cheers