- Joined

- Mar 12, 2014

- Messages

- 1,531

Very nice. Great job safely getting that down the stairs.

Mike.

Mike.

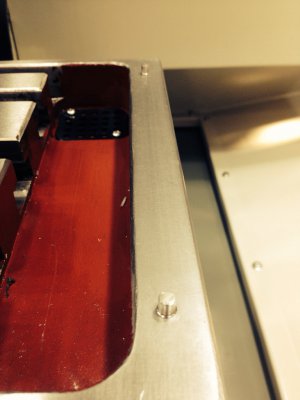

. Next up will be this cavity for an actual bottle tool I'm making. Did a dry run no tool and it seems like it will work. Steppers sure make funny sounds.

. Next up will be this cavity for an actual bottle tool I'm making. Did a dry run no tool and it seems like it will work. Steppers sure make funny sounds.