- Joined

- Mar 26, 2018

- Messages

- 2,724

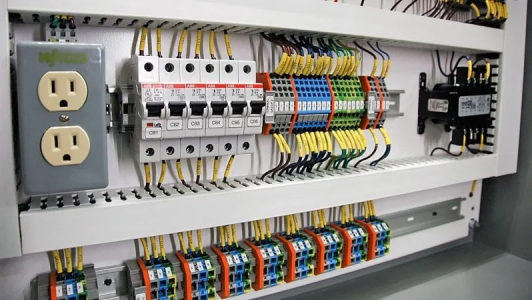

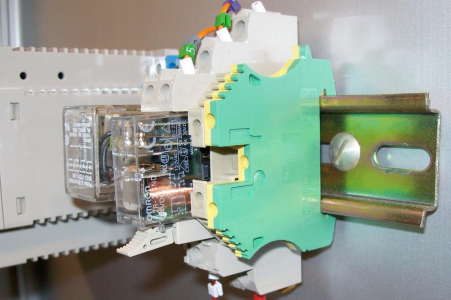

Tip #9: Wire Duct

When you are planning you panel, you should consider leaving room for wire duct. This is a plastic trough with fingers that allow you to bring your wires into a “highway” which runs between your components. Who cares if it gets messy since you will be snapping a clean looking cover on it? My source is AutomationDirect.

https://www.automationdirect.com/adc/shopping/catalog/wiring_solutions/wire_duct_-a-_accessories

When you are planning you panel, you should consider leaving room for wire duct. This is a plastic trough with fingers that allow you to bring your wires into a “highway” which runs between your components. Who cares if it gets messy since you will be snapping a clean looking cover on it? My source is AutomationDirect.

https://www.automationdirect.com/adc/shopping/catalog/wiring_solutions/wire_duct_-a-_accessories