-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Threading Set up question?

- Thread starter ljbenjam

- Start date

- Joined

- Apr 6, 2011

- Messages

- 2,082

Larry,

This funky looking part is called the "banjo"...

This one's supposedly off a 16".

-Ron

This funky looking part is called the "banjo"...

This one's supposedly off a 16".

-Ron

- Joined

- Mar 1, 2012

- Messages

- 1,140

- Joined

- Apr 28, 2012

- Messages

- 18

Ron,

Thanks. You have continued to educate me in what the pieces of the lathe are called. Yep that’s area I thought you were referring to. Banjo – huh….

To Old Machinist,

I have been called out of town for the weekend. I would bet you are on to the problem. That’s where I was headed. I may have to wait to get back home to do the counting. I have other photos with me that I may try to count from if I get some down time this weekend.

Ok how diD you get the photo to show on the page…. I have to learn that trick…

I just wanted to let folks know that were trying to help I have something else to deal with this week, than what I want to be doing….. But I would bet folks will understand how priorities get shifted……

Y’all have a great weekend.

Larry

Thanks. You have continued to educate me in what the pieces of the lathe are called. Yep that’s area I thought you were referring to. Banjo – huh….

To Old Machinist,

I have been called out of town for the weekend. I would bet you are on to the problem. That’s where I was headed. I may have to wait to get back home to do the counting. I have other photos with me that I may try to count from if I get some down time this weekend.

Ok how diD you get the photo to show on the page…. I have to learn that trick…

I just wanted to let folks know that were trying to help I have something else to deal with this week, than what I want to be doing….. But I would bet folks will understand how priorities get shifted……

Y’all have a great weekend.

Larry

- Joined

- Jun 17, 2011

- Messages

- 2,062

OM came to the same conclusion I did. 12 threads per inch is a pitch of 0.0833" - very close to the 0.0853 shown under the 4 on my lathe plate. Use the half-nuts, you get 4. Use the feed selector and the clutch, you get 12-ish.

The clutch doesn't let you engage the feed at the exact same point you did last time. Plus, it can slip - actually a good thing under some circumstances. It would be virtually impossible to cut a clean thread, even a 12/inch without using the half-nuts.

The clutch doesn't let you engage the feed at the exact same point you did last time. Plus, it can slip - actually a good thing under some circumstances. It would be virtually impossible to cut a clean thread, even a 12/inch without using the half-nuts.

- Joined

- Mar 1, 2012

- Messages

- 1,140

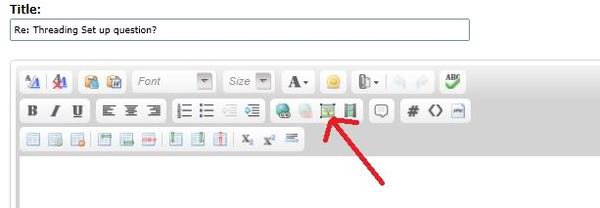

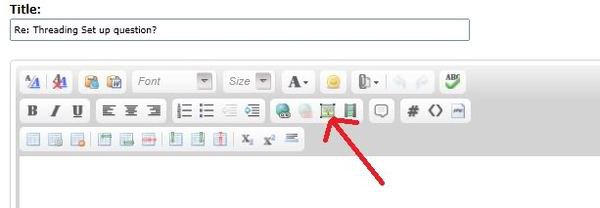

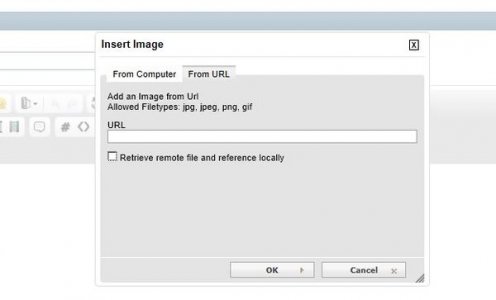

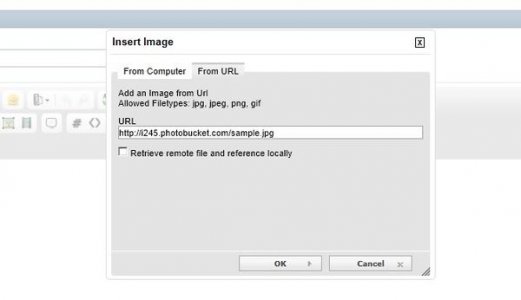

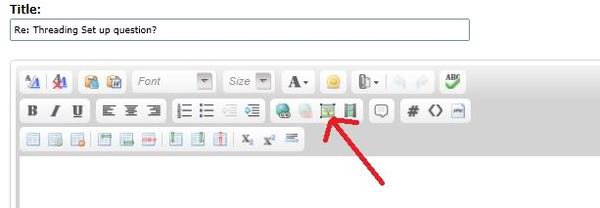

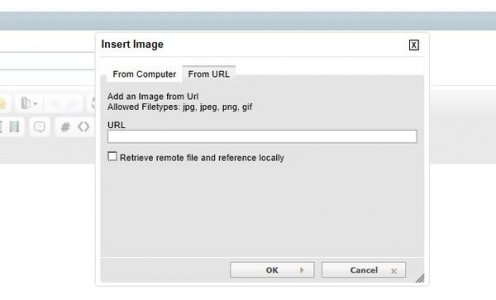

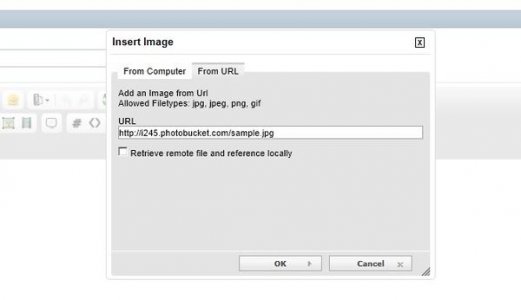

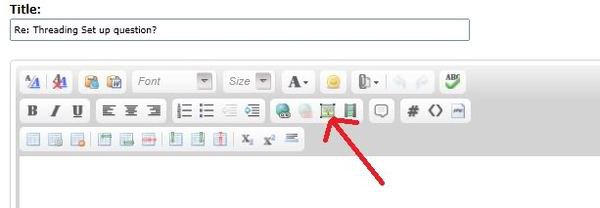

Re: Threading Set up question? Posting pictures

To post pictures I first store them on a free picture hosting site like PhotoBucket.com. Then click the insert image icon.

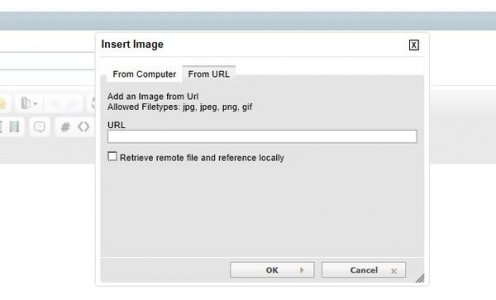

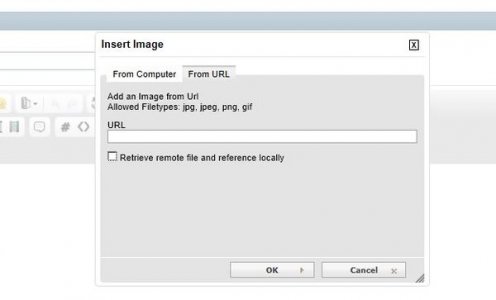

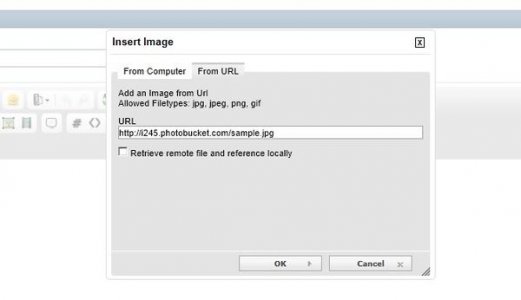

When the insert image window pops up click "From URL" and uncheck the "Retrieve remote file" checkmark.

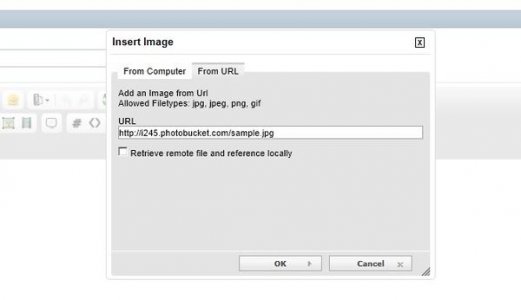

Then type or paste in the location of the image file and click OK.

The image should then be in your post wherever the curser was when you started.

To post pictures I first store them on a free picture hosting site like PhotoBucket.com. Then click the insert image icon.

When the insert image window pops up click "From URL" and uncheck the "Retrieve remote file" checkmark.

Then type or paste in the location of the image file and click OK.

The image should then be in your post wherever the curser was when you started.

- Joined

- Mar 1, 2012

- Messages

- 1,140

As long as the stud gear is 18 teeth then his gear train is all right. His lathe is a 16"/24" so it has a riser under the headstock with a couple of idler gears to reach the banjo.

- Joined

- Mar 1, 2012

- Messages

- 1,140

- Joined

- Apr 28, 2012

- Messages

- 18

Well finally back in town and have a chance to read y’alls input and put it to use.…. Thanks!

OM – you correctly diagnosed what I was doing… I was using the WRONG control, clutch versus the half nut. Like I said in my introduction this is a whole new learning endeavor for me. You are dealing with a rookie.

I appreciate everyone’s help and guidance.

I have been poking around the site for the manuals several folks have referenced. What am I missing? I seem to be missing them. I have grabbed some old ones off the web, but they did not contain OM’s drawing of the various control names/ purposes. Funny this site prides itself on saying read the manual…. But I think I need one. :thinking:

Larry

OM – you correctly diagnosed what I was doing… I was using the WRONG control, clutch versus the half nut. Like I said in my introduction this is a whole new learning endeavor for me. You are dealing with a rookie.

I appreciate everyone’s help and guidance.

I have been poking around the site for the manuals several folks have referenced. What am I missing? I seem to be missing them. I have grabbed some old ones off the web, but they did not contain OM’s drawing of the various control names/ purposes. Funny this site prides itself on saying read the manual…. But I think I need one. :thinking:

Larry

- Joined

- Apr 12, 2012

- Messages

- 579