- Joined

- Apr 28, 2012

- Messages

- 18

View attachment Photos for posting.pdf

Well you folks help resolve the “Leather Belt Slipping - 2 inch” so I am back learning again. :biggrin:

The issue I have run into is trying to thread a simple “square threaded jack screw”. I thought I had followed the “distructions” in How to Cut Screw Threads on a Lathe – Bulletin 36A – 1936 and LATHE WORK For Beginners, both South Bend Publications I found on Google and another Web Site from England.

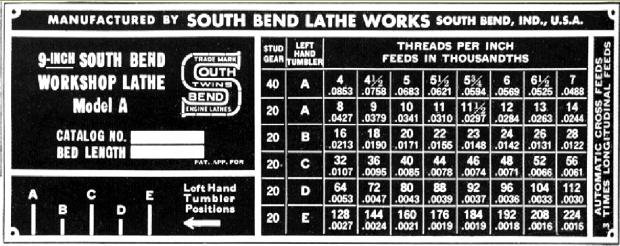

Not sure why I am getting 12 threads per inch versus the quick change plate, for 4 threads per inch. I have included pictures of plate, the setup on the machine. View attachment Photos for posting.pdf

The basic information of the lathe is Catalog 198G

Swing 16” with insert to raise to 24”

Bed Serial Number 170936

If I have not provided enough information to help troubleshoot the issue please let me know. But I am betting, this newbie, must be doing something that all the experience out there will recognize real fast.

(Still trying to figure out how to get get large photo files small enough for posting....) hope y'all can ope the PDF where I combined)

Larry

Well you folks help resolve the “Leather Belt Slipping - 2 inch” so I am back learning again. :biggrin:

The issue I have run into is trying to thread a simple “square threaded jack screw”. I thought I had followed the “distructions” in How to Cut Screw Threads on a Lathe – Bulletin 36A – 1936 and LATHE WORK For Beginners, both South Bend Publications I found on Google and another Web Site from England.

Not sure why I am getting 12 threads per inch versus the quick change plate, for 4 threads per inch. I have included pictures of plate, the setup on the machine. View attachment Photos for posting.pdf

The basic information of the lathe is Catalog 198G

Swing 16” with insert to raise to 24”

Bed Serial Number 170936

If I have not provided enough information to help troubleshoot the issue please let me know. But I am betting, this newbie, must be doing something that all the experience out there will recognize real fast.

(Still trying to figure out how to get get large photo files small enough for posting....) hope y'all can ope the PDF where I combined)

Larry