For me, it is partly about space. The shop, now under construction, is 5.5m x 3.6m (that's about 18ft x 12ft). Bigger than half a garage, but definitely modest compared to some enviable spaces we see here. I thought that one machine would suit better.

Getting deep down about TIG

It's a subtle thing, but some of the "multi" capability is about adding a sales feature. Sometimes when the term is used, it means MMA (stick) + TIG. All TIGs can do stick anyway.

Then there is the type of TIG. As I read it, if you have a MIG machine, adapted to TIG, it means the feed is stopped, and a different handle put on using tungsten electrode. Also, it may then be raw AC, but on some, in the spec (Miller) they say "DC TIG". From what you folk have been saying about TIG needing to be at least some kind of AC, I have to ask - is "DC TIG" really a thing?

Then you get to the more sophisticated genuine TIG features. High frequency pulsed DC is a kind of biased AC, and if the workpiece is made positive, you get less heat in the handle.

There may well be yet more sophisticated weld control feature I don't yet understand, but what we do have is a middle range of MIG welders that can do a "sort of" TIG, and will therefore plug this hard. There are some, generally costing more than $450 (£338) that do use modern electronics to achieve polarity reversal, and a "better" TIG. I note the Sherman calls their type "lift TIG. That is their word for "scratch start", and for some of the cheaper ones, the electrode is always live.

Then, as we get to the $800-$900 range, (£600 - £676) and still looking at those that claim to be "multi MIG + TIG", you then get to where the TIG feature is more fully served. Of course, we know that a $1000+ dedicated MIG machine (say Lincoln) is going to a fine welder. Folk who can fully use a something like this.. (

$3983)

View attachment 346030

Well - that is more than a hobby machinist investment,

and it is a dedicated TIG welder! No MIG!

- - - - - - - - - - - - - - - -

Back to the Polish Sherman, here is what $747 gets you.

-->

eBay MIG Welder TIG MMA DIGIMIG

View attachment 346032

Now look close at the claimed features..

Automatic setting, Predefined programs,

Welding aluminum, 2T / 4T,

Burnback, Gasless welding,

Stick welding,

TIG Lift,

Arc force, Hot start, Fan stop,

Settings memory, Anti Stick, VRD,

Voltage correction, Flux, Adjustable inductance,

Spool Gun compatible, Thermal Overload Protection

I have highlighted in red that it is a

scratch-start TIG.

It is a 60% duty cycle at 200A, and 100% at 155A machine that uses a 21V-240V input, and the price gets you everything in the picture.

- - - - - - - - - - - - -

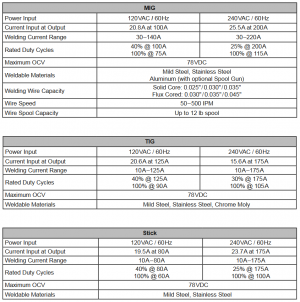

I have been dipping in here and there, getting a first idea from eBay, and Amazon, but I know that if you want a Miller Multiprocess of any kind, it's going to take you past $1800+, and gets to $3000 - $4000. You will want to check out the welding shop in your home town, or maybe use the brand website. There are some surprisingly good welders available at good ole' Harbor Freight.

- - - - - - - - - - - -

Despite the space issue, I am going to go for a nice dedicated MIG, and use the HobbyWeld deposit-only no rental gas cylinder, and then, if in the future I want to play TIG, I will use a dedicated TIG with RF start, and current waveform PWM (pulse width modulation) control.