- Joined

- Aug 12, 2014

- Messages

- 269

Serial taps.As @francist said we live in an industrial no-mans-land.

Slight diversion: what is the significance of the machines lines on these seemingly identical taps?

Sent from my iPhone using Tapatalk

John

Serial taps.As @francist said we live in an industrial no-mans-land.

Slight diversion: what is the significance of the machines lines on these seemingly identical taps?

Sent from my iPhone using Tapatalk

My understanding is that solid dies are for thread chasing. Not good for threading.

Serial taps.

John

You can use them that way but they are usually used in hard metals.This makes sense to me.

Three passes to a fully tapped blind hole?

A through hole can be done with a single tap right?

Sent from my iPhone using Tapatalk

The die handles with adjustable guides are the only way to fly. I get a pretty straight start most times depending on the type of metal. But nothing beats threading on a lathe for dead true threads.I've heard that before but haven't found it to be especially true. You don't get to adjust for fit with solid dies for sure, but all else being equal I've found they cut the same. Getting the die started straight is the biggest issue I've ever had, wether with solid or split dies. Making a tailstock die holder made a HUGE difference!

Welcome to the world of making tools to make tools and on and on. Like Aaron W mentioned another handy project for me was making an adapter to mount a hand crank in the end of my lathe head to crank by hand. My 9x20 doesn't go slow enough for me to feel comfortable threading short threads on the lathe. The hand crank did the trick. When I get more experience I probably won't need it but for real short theads and for using a die in the lathe it works for me.Thanks @C-Bag

I see folks using tap handles in conjunction with some sort of spring loaded tooling in the tailstock.

Looks like a good project

Is the chuck open all the way so that there's a flat bearing surface againt the die holder?A real simple but effective way that doesn't require any special tools, is simply chuck up the part to be threaded with a die, then use a tail stock drill chuck to help hold the die straight. Rotate the chuck by hand, and keep a light pressure on the tail stock until it starts threading. Once started, then turning the chuck will just pull the die forward. None of this is under power, all hand turning.

Not my creation, I got the idea from a Mr Pete video on using taps and dies.

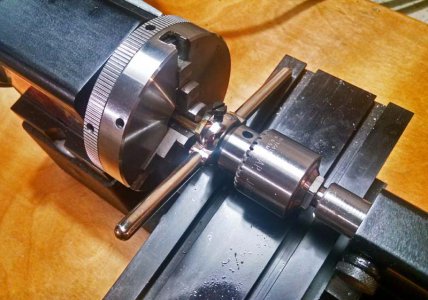

View attachment 305816

The finished part

View attachment 305817

The original idea

Mr Pete threading with a die #3