- Joined

- Apr 1, 2013

- Messages

- 1,142

Yes it is a good problem to have ) And as I have stated nota real bad one. Yes I changed feed rates and did it by hand both with the carriage and the compound no notable change. Not sure how Icould measure this.

) And as I have stated nota real bad one. Yes I changed feed rates and did it by hand both with the carriage and the compound no notable change. Not sure how Icould measure this.

Yes I am trying to rule things out andI am pretty sure for thereasons above it is not in the leadscrew or carriage feed.

The bearing theory is notas unlikely as you may think, 1) these machines do havesome issuesthere, 2) I did crash the compound into the chuck way back.

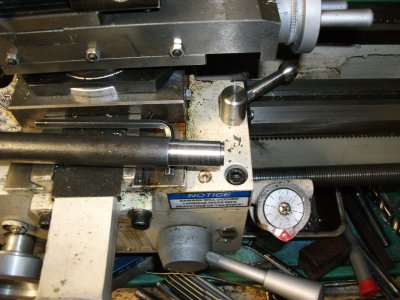

I do have a better photo, but I think it makes it look worse than it is but at least you can see the pattern.

I think that it could be a bearing and that the reason for the spiral effect is a dent or pit itthe roller hit the pit (or it could be a raised up spot) at a different rate than the spindle speed or ratio that would cause the mark to advance in respects to the rotation of the part.(make any sense)

Well look at the photo and tell me what you think.

Yes I am trying to rule things out andI am pretty sure for thereasons above it is not in the leadscrew or carriage feed.

The bearing theory is notas unlikely as you may think, 1) these machines do havesome issuesthere, 2) I did crash the compound into the chuck way back.

I do have a better photo, but I think it makes it look worse than it is but at least you can see the pattern.

I think that it could be a bearing and that the reason for the spiral effect is a dent or pit itthe roller hit the pit (or it could be a raised up spot) at a different rate than the spindle speed or ratio that would cause the mark to advance in respects to the rotation of the part.(make any sense)

Well look at the photo and tell me what you think.