Time to make the Plummer blocks. Let’s try super glue

.

Well that didn’t work very well. You can see where the glue failed and the tool dug in. Should have listened to Joe Py.

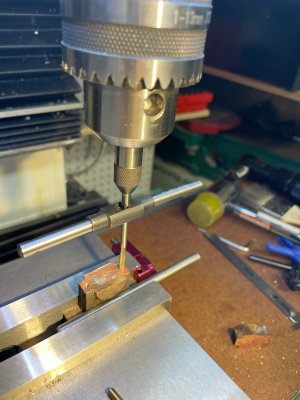

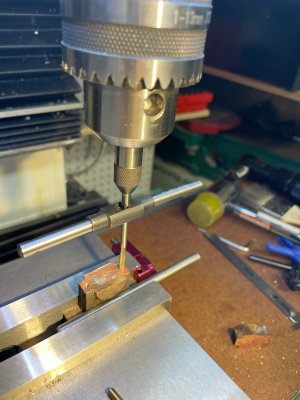

Need to drill and tap so I can bolt the halves together,

Now lets turn the faces.

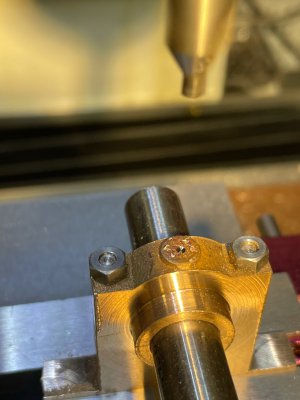

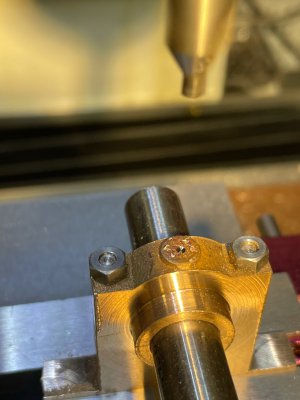

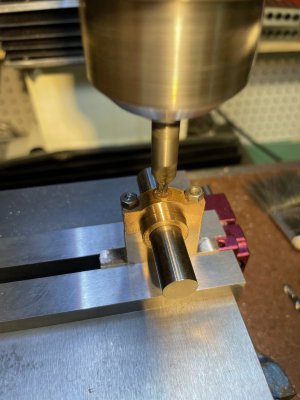

Much better. I tried boring them on the lathe using the ruined part shown above and learned that the red brass would catch the bits and reamer and leave a mess. So I decided to do the boring on the mill. Locate the base and center set the bore center

.

Drill and ream. Check with a gauge pin. Good fit.

Use the gauge pin to check center and drill holes for the base and oil cup.

Everything fits and the beam pivots without binding.

Next up the watts parallel motion links and miscellaneous parts

.

Well that didn’t work very well. You can see where the glue failed and the tool dug in. Should have listened to Joe Py.

Need to drill and tap so I can bolt the halves together,

Now lets turn the faces.

Much better. I tried boring them on the lathe using the ruined part shown above and learned that the red brass would catch the bits and reamer and leave a mess. So I decided to do the boring on the mill. Locate the base and center set the bore center

.

Drill and ream. Check with a gauge pin. Good fit.

Use the gauge pin to check center and drill holes for the base and oil cup.

Everything fits and the beam pivots without binding.

Next up the watts parallel motion links and miscellaneous parts

Attachments

-

09238BEF-5E04-461D-8ACE-7DDE96489DAE.jpeg701.2 KB · Views: 12

09238BEF-5E04-461D-8ACE-7DDE96489DAE.jpeg701.2 KB · Views: 12 -

50699D41-AE5C-4AE0-8E72-867D96F3CB3B.jpeg887.4 KB · Views: 11

50699D41-AE5C-4AE0-8E72-867D96F3CB3B.jpeg887.4 KB · Views: 11 -

B5EFFA9B-4187-416D-93ED-7815A6003770.jpeg757.2 KB · Views: 14

B5EFFA9B-4187-416D-93ED-7815A6003770.jpeg757.2 KB · Views: 14 -

A14A7D4F-2B8F-4CA0-AB39-AFA7C09032EB.jpeg906.4 KB · Views: 11

A14A7D4F-2B8F-4CA0-AB39-AFA7C09032EB.jpeg906.4 KB · Views: 11 -

B71FB544-C527-40FC-9ED5-021E98117DB9.jpeg755 KB · Views: 10

B71FB544-C527-40FC-9ED5-021E98117DB9.jpeg755 KB · Views: 10 -

FE0D5E8A-1A50-4D8A-B22B-35553E666772.jpeg670.8 KB · Views: 9

FE0D5E8A-1A50-4D8A-B22B-35553E666772.jpeg670.8 KB · Views: 9 -

EBBA065E-8E29-41A3-BF70-ECF67376BA7A.jpeg631 KB · Views: 9

EBBA065E-8E29-41A3-BF70-ECF67376BA7A.jpeg631 KB · Views: 9 -

F4F0A38C-6789-4441-A58E-700663B68FA1.jpeg821.4 KB · Views: 12

F4F0A38C-6789-4441-A58E-700663B68FA1.jpeg821.4 KB · Views: 12