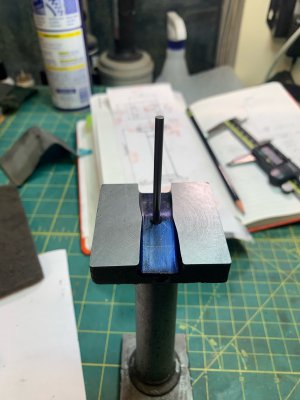

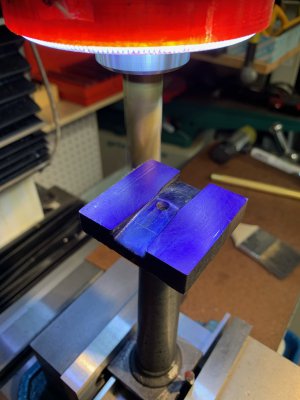

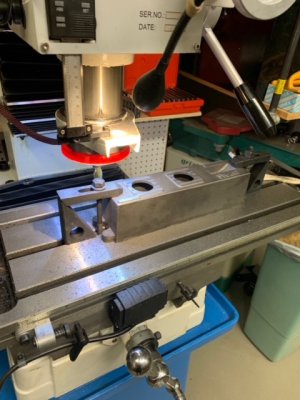

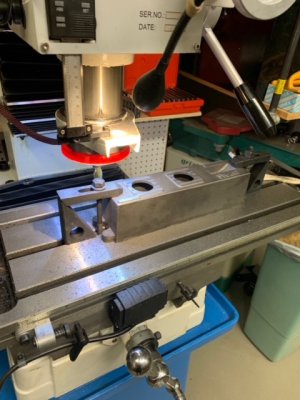

Starting a Stuart Beam Engine. Finished the machining the base and the crank support(pictures below).

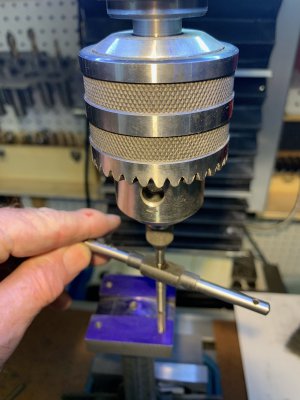

On to the column. I am in a quandary on how to set everything up and order of operations. I figured I would turn the column between centers, but my first attempt to find center using diagonals from the corners of the base and column capital was a spectacular failure. Wasn't even close to concentric with the column. So, machine .376" cast iron to go into .375" holes and start again.

This go round I used my surface plate and transferred a line that was tangent to the column to the underside of the column base and capital. Better, but still between 20 and 30 thou of runout. I know the casting shouldn't be a registration surface, but I want to at least make it so it looks somewhat concentric.

OCD kicking in I guess. Glad this is a hobby. I would go broke in short order if I was doing this for a living.

Suggestions for setting the centers for concentricity?

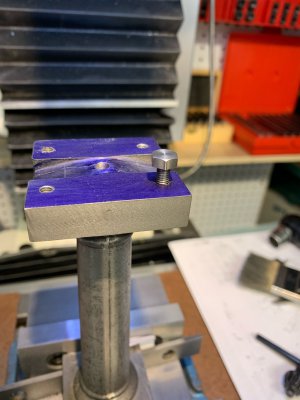

Now to the real problem. The column supports the bearings for the Watts Parallel Motion assembly and piston rod. These components mount to the entablature beams supported by the column. Therefore, the entablature beams must be parallel and equidistant from the piston centerline. Working backwards then the column base bolts must be normal to the major x and y axis on the box bed to make sure the column capital and entablature beams are properly aligned.

How do I insure I reference these axes properly when I set the bolt holes in the base of the column?

.

.

Align the base, deck the surface to spec, check the first hole location for sanity then use the DRO to set all the other holes in proper relation.

On to the column. I am in a quandary on how to set everything up and order of operations. I figured I would turn the column between centers, but my first attempt to find center using diagonals from the corners of the base and column capital was a spectacular failure. Wasn't even close to concentric with the column. So, machine .376" cast iron to go into .375" holes and start again.

This go round I used my surface plate and transferred a line that was tangent to the column to the underside of the column base and capital. Better, but still between 20 and 30 thou of runout. I know the casting shouldn't be a registration surface, but I want to at least make it so it looks somewhat concentric.

OCD kicking in I guess. Glad this is a hobby. I would go broke in short order if I was doing this for a living.

Suggestions for setting the centers for concentricity?

Now to the real problem. The column supports the bearings for the Watts Parallel Motion assembly and piston rod. These components mount to the entablature beams supported by the column. Therefore, the entablature beams must be parallel and equidistant from the piston centerline. Working backwards then the column base bolts must be normal to the major x and y axis on the box bed to make sure the column capital and entablature beams are properly aligned.

How do I insure I reference these axes properly when I set the bolt holes in the base of the column?

.

.

Align the base, deck the surface to spec, check the first hole location for sanity then use the DRO to set all the other holes in proper relation.