- Joined

- May 26, 2015

- Messages

- 762

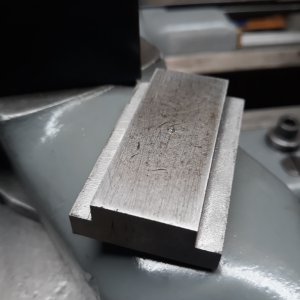

Yes I did as discussed in previous posting. All the jaws were numbered to match chuck numbers so no mix up. I Was up early this morning so I finished grinding jaws down to .001” runout.Before you went ahead and screwed up your chuck, did you AT LEAST disassemble it and check for swarf caught in the scroll or threads?