- Joined

- May 26, 2015

- Messages

- 762

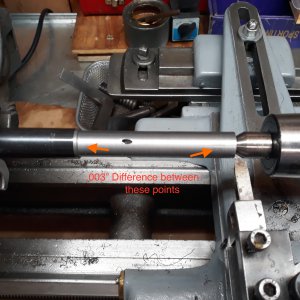

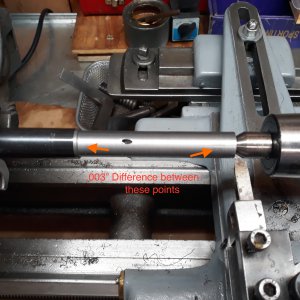

Did a cut test to find out the way wear between two points. At 2-1/4" from chuck jaws I was off .003" from 5-3/4" out due to the further out I went the better the ways got and tolerance got tighter. Don't guess there is anything that can be done short of finding a derelick 9A just for the bed and I don't think that's going to happen with me. In the pic you can see the wear lip at the top of the way! (Just above the text.)