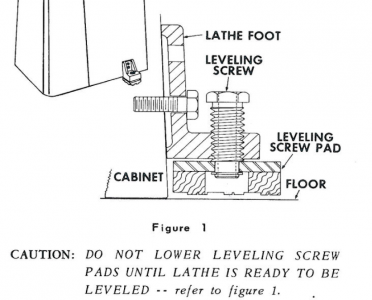

Got the lathe where I think it’s best Owners manual said to use the special feet under the adjusting screws but I didn’t get them Does anyone know what I should use ?

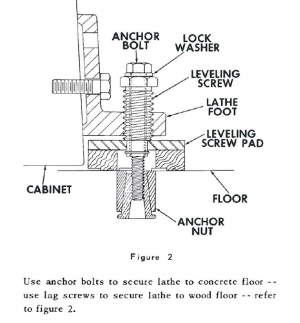

Mine came with the pads for leveling (well 3 and a half of them anyway). They are just some steel plate (3/16 I think) with a hole in it to capture the reduced end of the leveling bolts (did you get these?). Attached to the underside of the steel plate is some hard rubber (maybe fiber reinforced?). I was missing one of the rubber pieces so I just went ahead and replaced them all with some new stuff (not reinforced, but has held up ok for the past few months of use).