-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Smithy parts drying up

- Thread starter mac1911

- Start date

I need both cross feed snd lead screw nutWhat acme shaft and nut are you looking for? My bench lathe is similar to yours . When I made the crossfeed shaft my Clausing I had ordered extra in case in messed up . I used the extra 5/8- 10LH to change the bench top crossfeed from metric to Imperial. Extended the travel by adding an extension to the front and extra length so it would be easier to cut from the backside in reverse if needed . It was the first time I tried an internal thread for the nut . Also had to make a new handwheel in inches. Picture shows the old handwheel

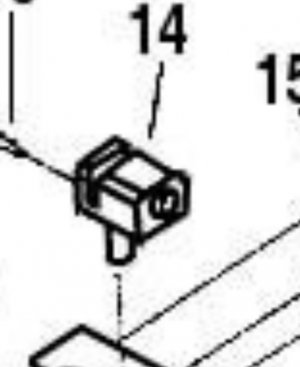

#14 is a 2 piece nut for cross slide

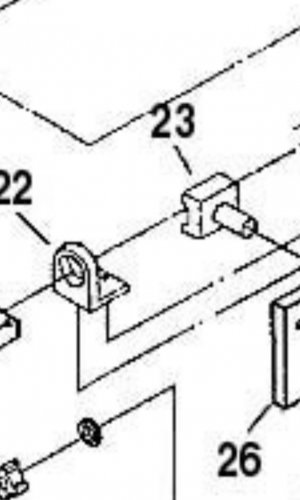

#23 is just half a nut the pushed against the scree and into the plate

#22- the plate I think I can flip around short term.

The ones that have popped up local to me are are well worn and needing most the same and missing or dont have the rests, faceplate and other accessories.Rather than grind on high-speed steel, get some tool steel O-1 or A-2, shape it by sawing, milling or whatever and then harden it.

Also, I periodically see these machines on craigslist or facebook and you could get a "parts car"

They are always shifting designs.That’s a nice machine . Its a shame there not stocking parts or the ones they do at a reasonable price

My model is from the mid 90s they changed it to the Midas LTD and changed up the carriage/apron design…

I cant afford to buy anything different. I got this one cheap

The few hundred in parts if they had them would have been great vs buying something newer.

I will get there eventually.

In the meantime I might try the loctite thread repair to get me by.

Last edited:

Im sure someone does/canI’m surprised no one on this forum offers these services. Seems like somebody could make some decent side money making wearable parts, especially for these machines.

I will assume the cost is prohibitive on a lower “value” machine.

Then theres people like me if its going to cost me several hundred I will most likely spend that money on the tools/material to make it myself.

So I tried to at least get the specs for the parts I need that they cant supply.

Per our technician, we do not have diagrams of the individual parts available - you'll need to reverse engineer the part in order to reproduce it. The most information available was that the parts that you mention have an acme thread profile.

Detroit Machine Tools - AutoMateCNC and Smithy

855-422-7745

Per our technician, we do not have diagrams of the individual parts available - you'll need to reverse engineer the part in order to reproduce it. The most information available was that the parts that you mention have an acme thread profile.

Detroit Machine Tools - AutoMateCNC and Smithy

855-422-7745