-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

slodat's 3d printed shop projects

- Thread starter slodat

- Start date

- Joined

- Jan 20, 2021

- Messages

- 296

Thank you!

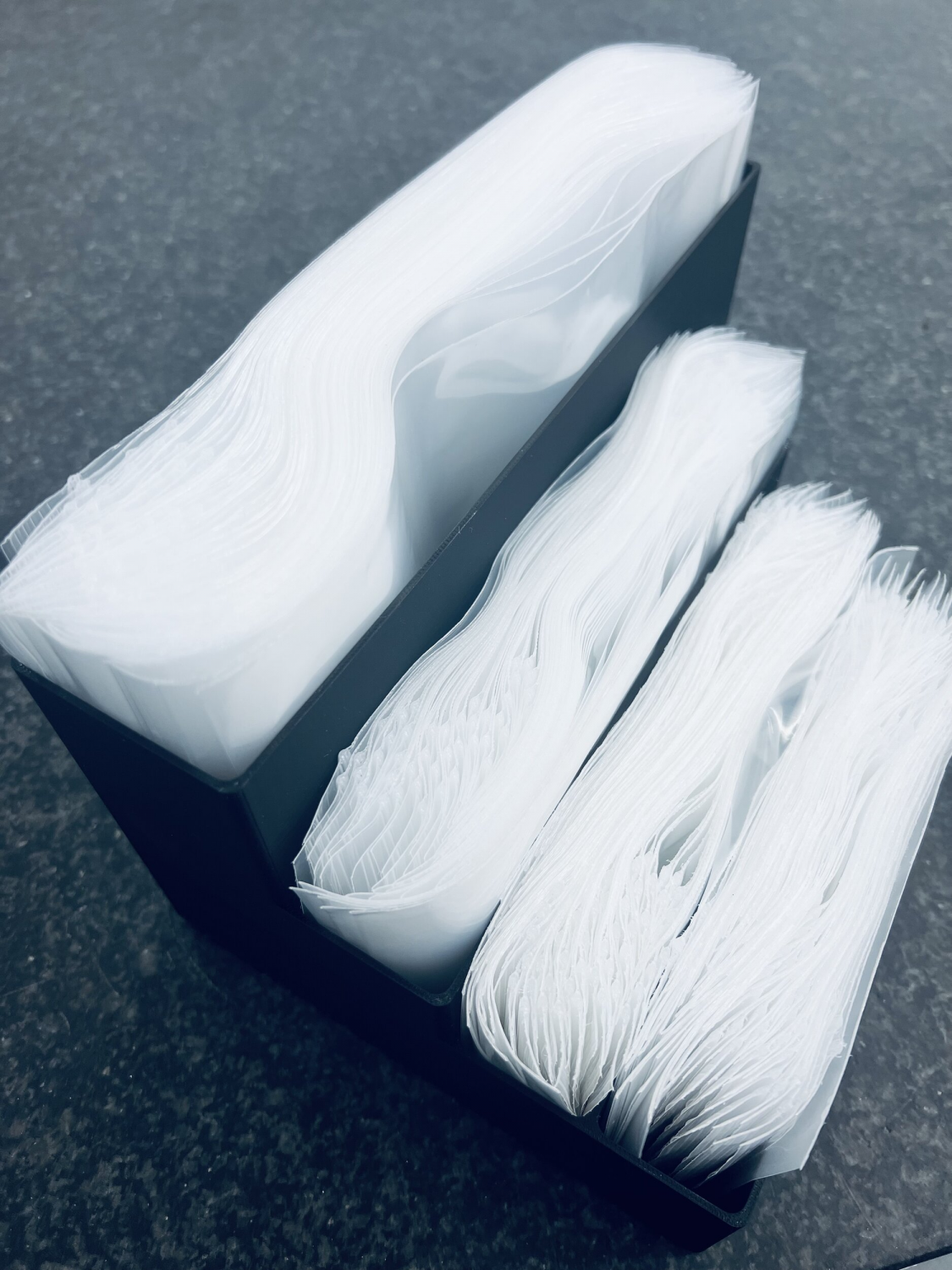

Came into some nice prints this morning. On the way out the door last night I came up with an idea for an organizer..

The X1C printed what I see as a perfect part.

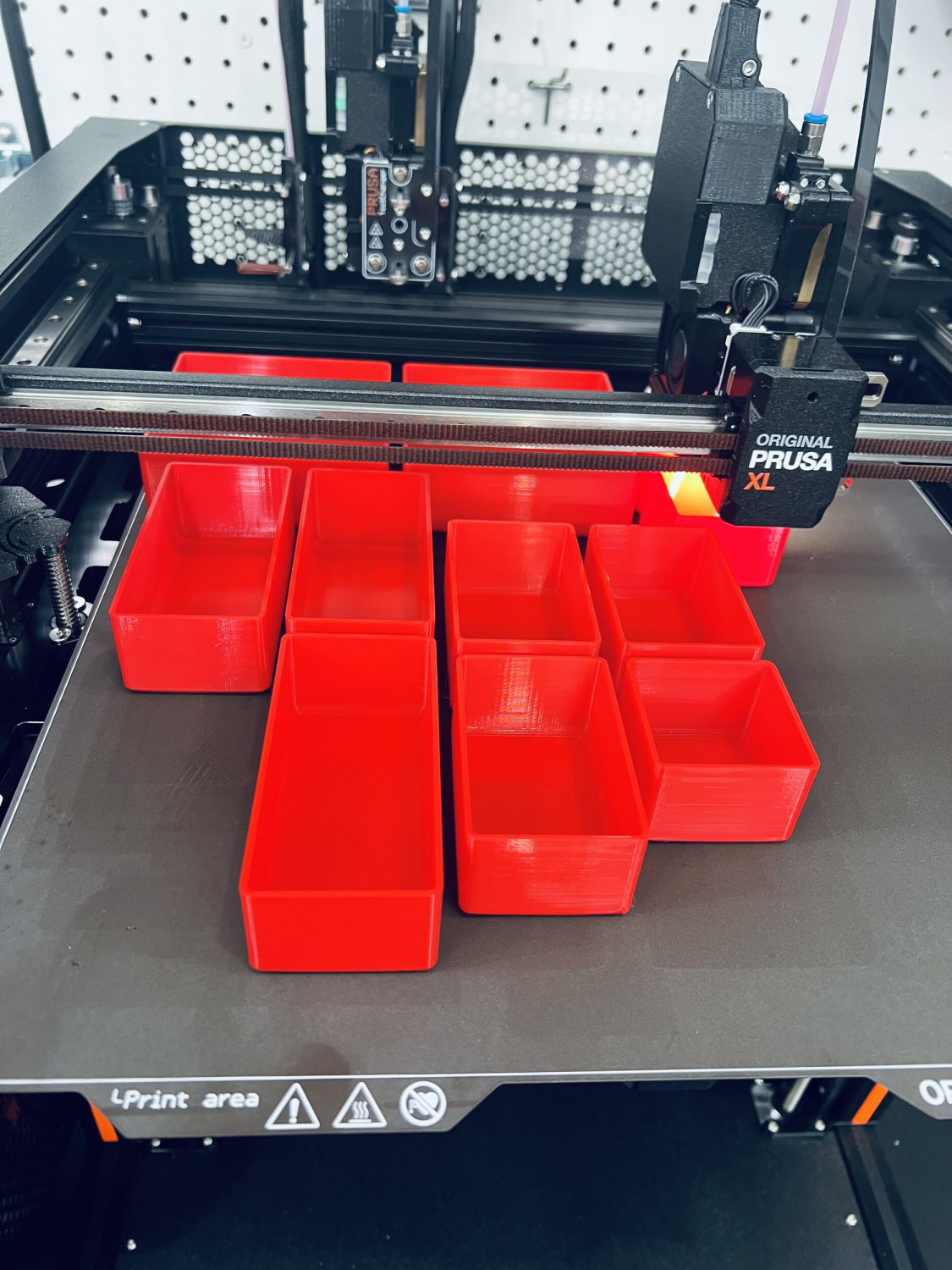

The XL is still completing its overnight job:

The other X1C made these:

And the gray bins for fine pitch threads worked out great:

Having that different color will do the trick to help ensure the right stuff gets packed out.

Up next for the XL:

Came into some nice prints this morning. On the way out the door last night I came up with an idea for an organizer..

The X1C printed what I see as a perfect part.

The XL is still completing its overnight job:

The other X1C made these:

And the gray bins for fine pitch threads worked out great:

Having that different color will do the trick to help ensure the right stuff gets packed out.

Up next for the XL:

Last edited:

- Joined

- Jan 7, 2016

- Messages

- 3,273

I too have been doing some bins. Instead of different colors for the bins I use different colored labels.

Attachments

- Joined

- Jan 20, 2021

- Messages

- 296

Zip lock bags.What is in the second picture?

- Joined

- Jan 20, 2021

- Messages

- 296

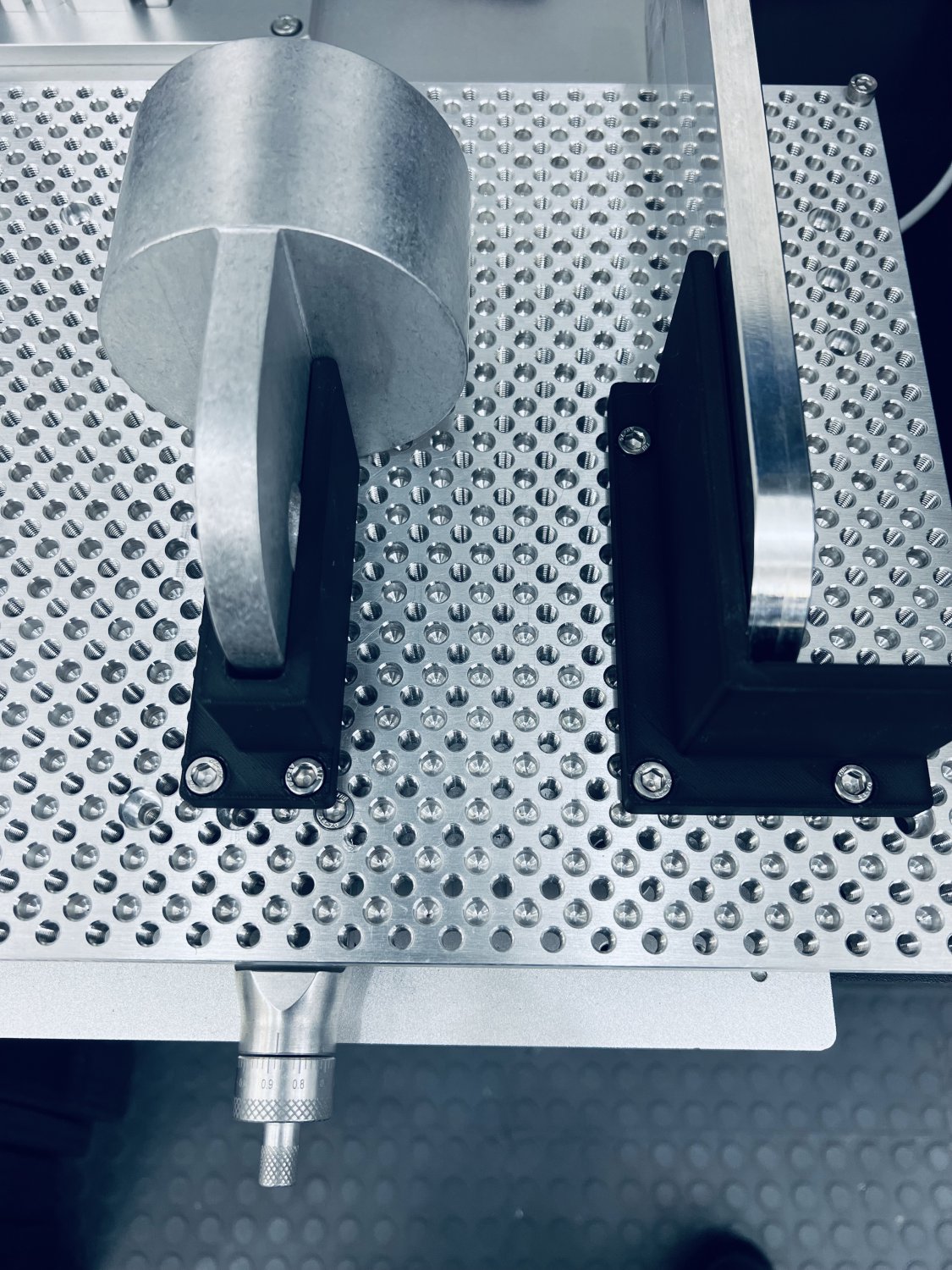

One of the many ways 3D printing really is a game changer in the shop. I needed a way to hold some of my parts for engraving on the short edge. And, I wanted it repeatable. A few minutes in Fusion 360 and a couple hours on the X1C and I have a workable solution.

It’s not that these couldn’t be made other ways. It’s that this takes very little of my time, there’s no setup, and they lack nothing.

It’s not that these couldn’t be made other ways. It’s that this takes very little of my time, there’s no setup, and they lack nothing.

- Joined

- Jan 20, 2021

- Messages

- 296

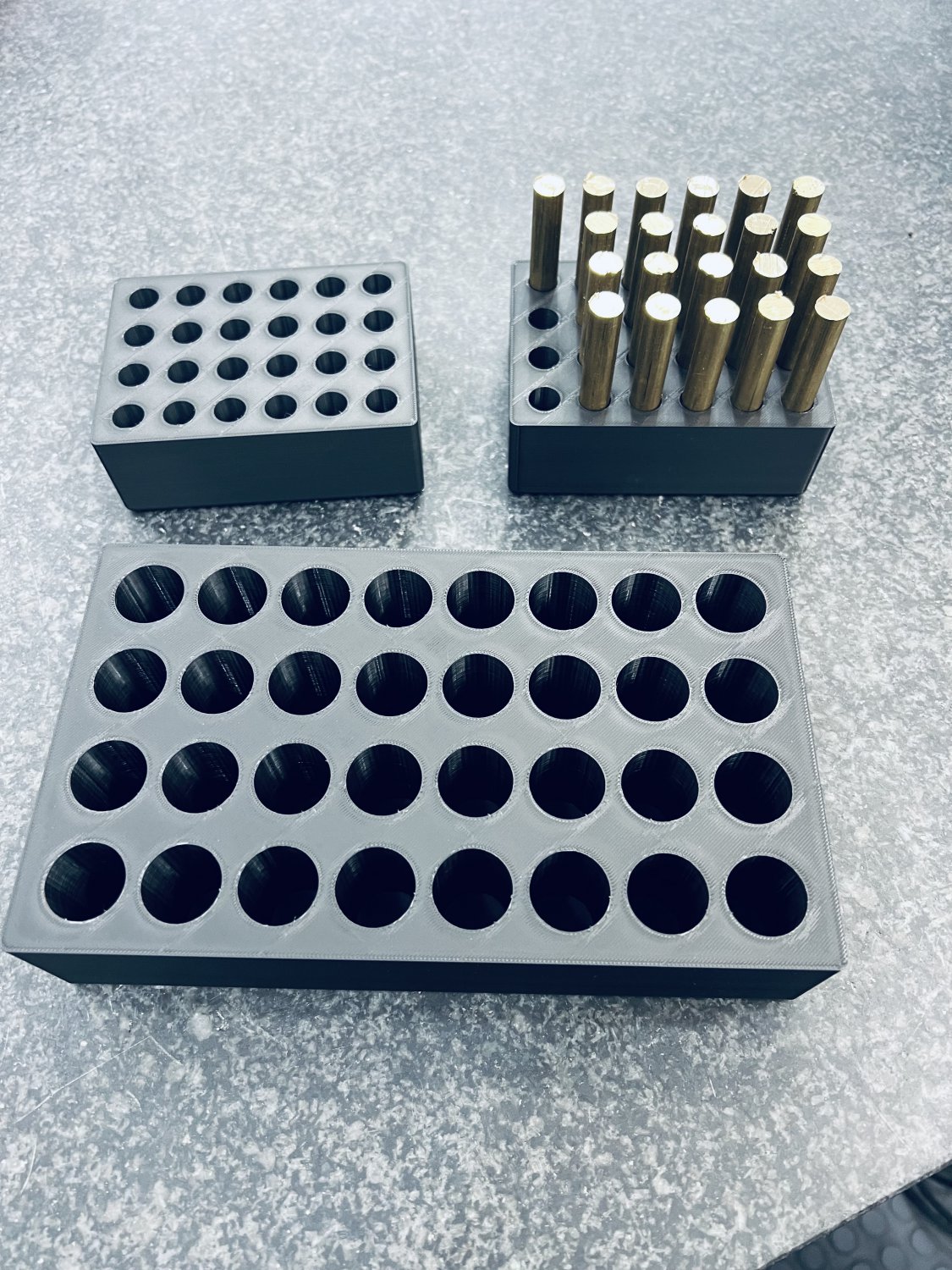

Ran a few each of these work in progress blocks on the X1C’s. They turn out really nice and will help with the production of these parts.

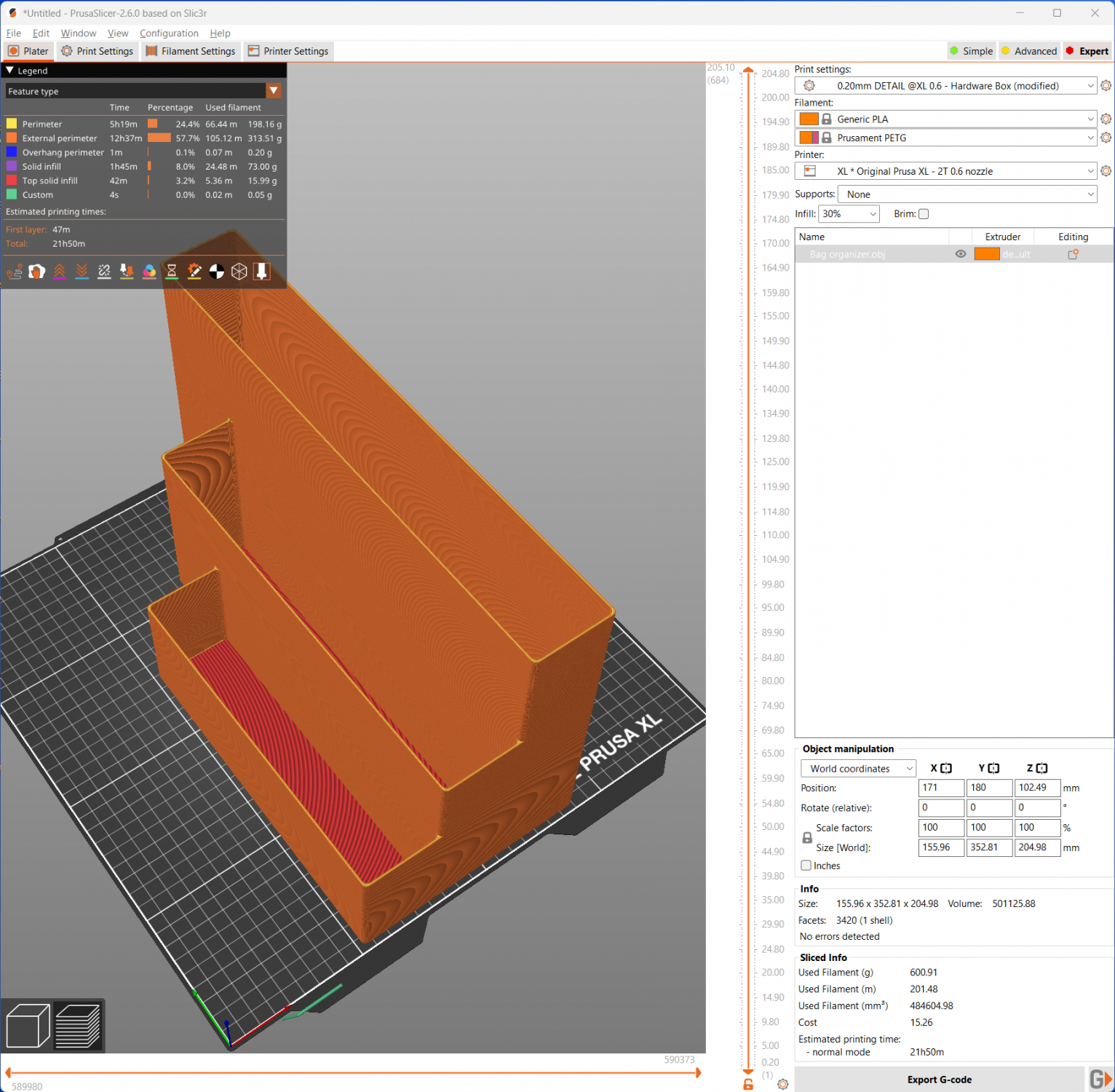

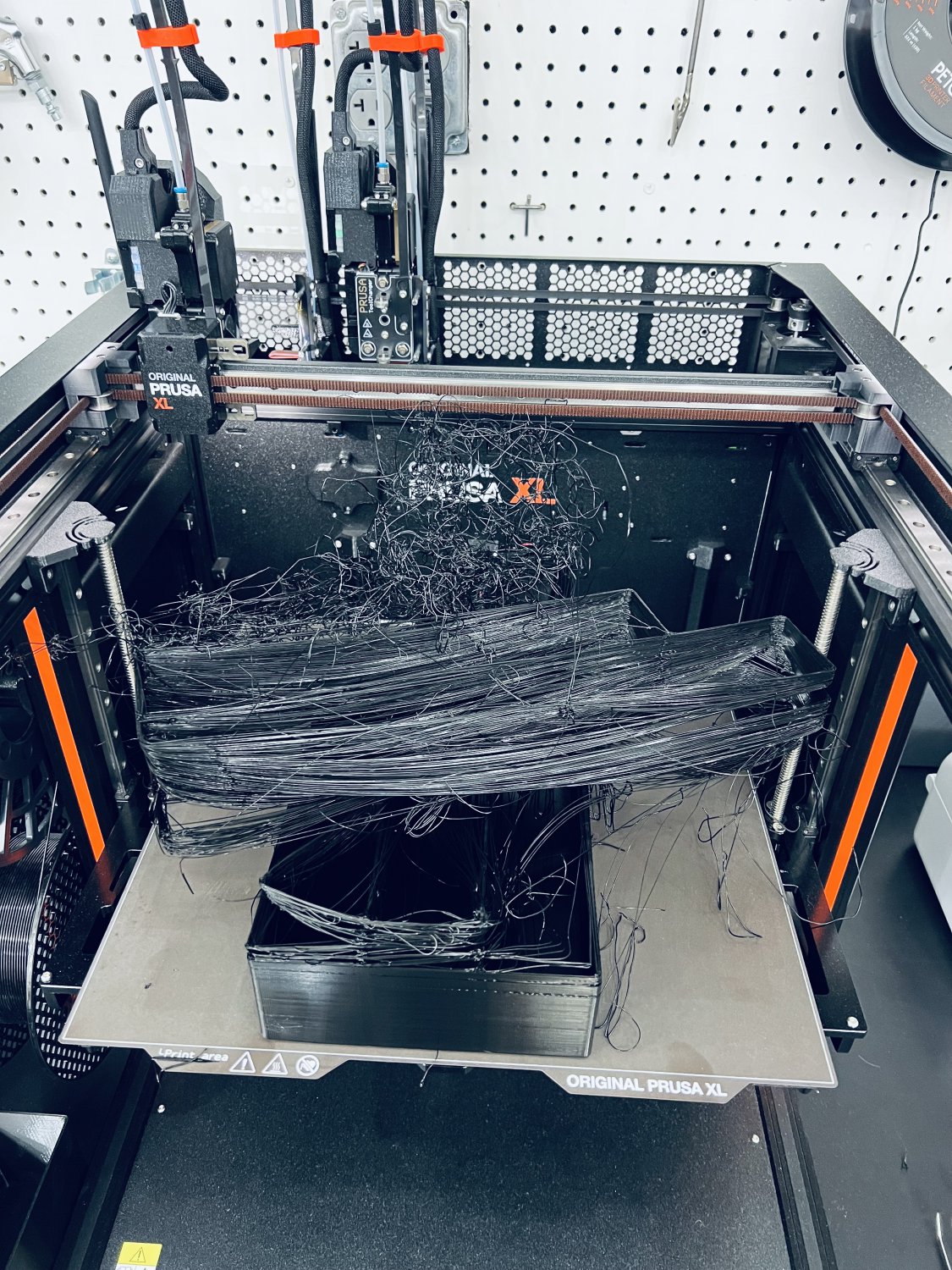

I wanted to print another bag organizer on the XL for the larger bags. The first attempt failed:

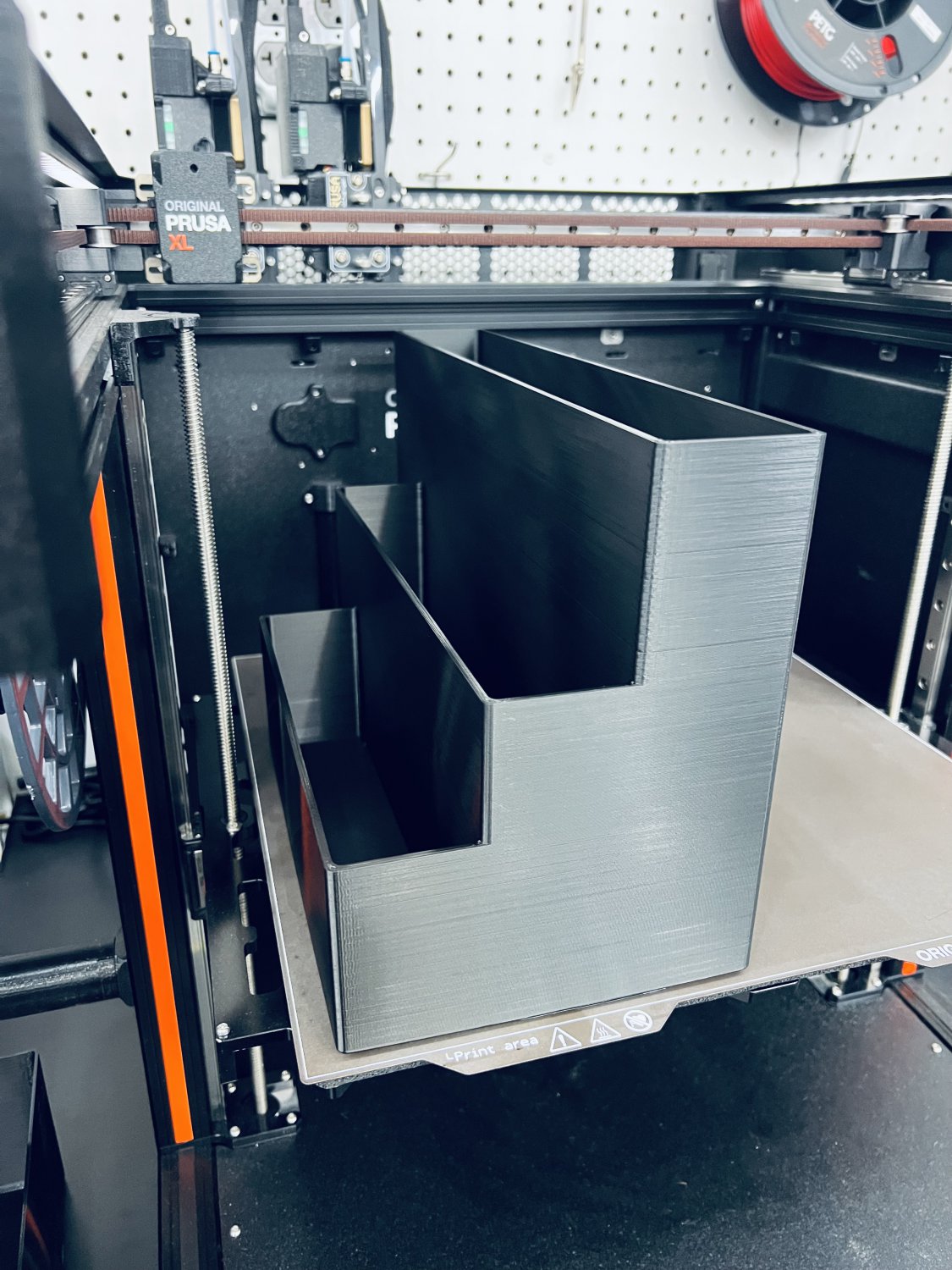

The control panel stated the fan had failed. A reboot appeared to fix it. The second attempt failed as well. It stopped extruding. I believe that hotend is clogged bad. I switched to the other tool head and got a successful print.

As I use the XL more I feel it’s going to get better over time. This is historically how Prusa does things. A few things aren’t there that are quite surprising. I had to reslice the project to switch to the other tool head. I’ve had issues where the wifi doesn’t work at all requiring multiple reboots. It doesn’t switch toolheads when it runs out of filament and other toolheads have that filament loaded.

I love the print quality. The big bag organizer is 12” wide, 6.5” deep, 8” tall. That’s a great looking print at that size.

I wanted to print another bag organizer on the XL for the larger bags. The first attempt failed:

The control panel stated the fan had failed. A reboot appeared to fix it. The second attempt failed as well. It stopped extruding. I believe that hotend is clogged bad. I switched to the other tool head and got a successful print.

As I use the XL more I feel it’s going to get better over time. This is historically how Prusa does things. A few things aren’t there that are quite surprising. I had to reslice the project to switch to the other tool head. I’ve had issues where the wifi doesn’t work at all requiring multiple reboots. It doesn’t switch toolheads when it runs out of filament and other toolheads have that filament loaded.

I love the print quality. The big bag organizer is 12” wide, 6.5” deep, 8” tall. That’s a great looking print at that size.

Thanks for sharing your experiences and designs slodat.

I am a new to 3D printing. So far i have just read info, and watched videos.

I had many years as a machinist and tool and die maker.

I have a couple of 60's Fords i have been modding for several years and i could see the printer making a difference. I also have a full sized mill and lathe.

Would i be ok going "all in" as my first printer with the X1 Carbon, or should i go for a P1S with AMS? I want to do multi color parts and would like strong carbon for brackets, etc.

Thanks, Joe

I am a new to 3D printing. So far i have just read info, and watched videos.

I had many years as a machinist and tool and die maker.

I have a couple of 60's Fords i have been modding for several years and i could see the printer making a difference. I also have a full sized mill and lathe.

Would i be ok going "all in" as my first printer with the X1 Carbon, or should i go for a P1S with AMS? I want to do multi color parts and would like strong carbon for brackets, etc.

Thanks, Joe

- Joined

- Jan 20, 2021

- Messages

- 296

Joe- my advice is to go with the X1C Combo. I have two of them. I’ve been very happy with them. Especially if you’re wanting to use the higher tech filaments. I print a lot of ABS and it does a great job!