- Joined

- Dec 25, 2010

- Messages

- 79

Re: Show us your

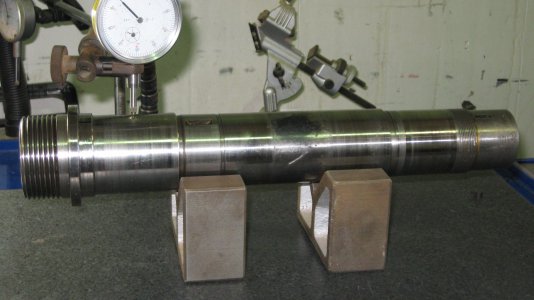

I have proved to myself that it is in fact a bent spindle on my Heavy 10. I took it out of the headstock and used a set of V blocks and a dail indicator on a granite slab. It appears to be bent at point of the bearing surface. And I do have another Spindle and a whole other headstock on the way. When it was installed I measured at the nose and got .008" and when I had it removed I got .006" on the bearing surface and then checked at the nose and got the same .008" as before. I had to prove it to myself and then show the rest of you guys.

I have proved to myself that it is in fact a bent spindle on my Heavy 10. I took it out of the headstock and used a set of V blocks and a dail indicator on a granite slab. It appears to be bent at point of the bearing surface. And I do have another Spindle and a whole other headstock on the way. When it was installed I measured at the nose and got .008" and when I had it removed I got .006" on the bearing surface and then checked at the nose and got the same .008" as before. I had to prove it to myself and then show the rest of you guys.

Last edited by a moderator: