Main reason that I have kept mine, ( right alongside my 9A in the basement).Actually, the "Junior" designation is before the standard 9a, b and c. And it is a misnomer as to size in comparison. It is also known as a "Wide Bed". The ways are further apart and it is more beefy than my 9A. Weights a little more too.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SB 9 Junior

- Thread starter ShagDog

- Start date

- Joined

- Feb 28, 2019

- Messages

- 499

Ok, yeah I have a 9A and love it. It was kind of hard to tell the differences from your pictures.

Thanks for the enlightenment.

Thanks for the enlightenment.

Made a bench for the Junior. Cut some steel with it. Runs well, except the motor assembly appear to have excessive vibration, but it does not seem to affect the cutting. Still need to figure out a system to enable me to adjust belt tension with the self contained motor assembly. As to the vibration, I do have another motor laying around that I may try. I am pleased with this lathe. I will eventually fix the broken teeth on the bull gear.

- Joined

- Sep 1, 2018

- Messages

- 652

I have a 36” 9”wide bed that I’ve had for appx. 5-7 years put up for future project that’s not gonna happen. Matter of fact have lots of stuff in same category. Gotta quit thinking I’ll get around to it one day.

Looks like you are missing the turn-buckle belt tensioner?Made a bench for the Junior. Cut some steel with it. Runs well, except the motor assembly appear to have excessive vibration, but it does not seem to affect the cutting. Still need to figure out a system to enable me to adjust belt tension with the self contained motor assembly. As to the vibration, I do have another motor laying around that I may try. I am pleased with this lathe. I will eventually fix the broken teeth on the bull gear.

Pin and oxy-acetylene braze the bull gear teeth, file to shape.

- Joined

- Aug 6, 2015

- Messages

- 3,892

You are among great company!I have a 36” 9”wide bed that I’ve had for appx. 5-7 years put up for future project that’s not gonna happen. Matter of fact have lots of stuff in same category. Gotta quit thinking I’ll get around to it one day.

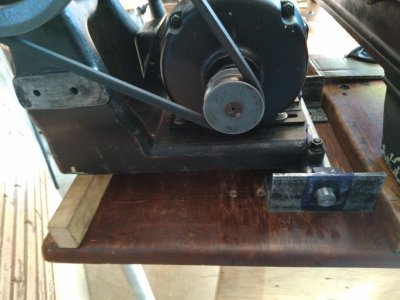

The self contained motor unit does not use the same system with the turn-buckle. It is a little difficult to tell from the pictures, but see the pictures in my 1st post in this thread, and there is no kind of swivel on the bracket. I was thinking I would make tracks for it to slide in and out. For now, I am able to slide the belt off and on, but the tension is not sufficient if i want to take a heavier cut.Looks like you are missing the turn-buckle belt tensioner?

Pin and oxy-acetylene braze the bull gear teeth, file to shape.

I was able to do the repair with pins I threaded in (instead of welding; no welder) across where the tooth would be on my back gear on my 9a. This one has the teeth missing on the bull gear in 2 locations. The more difficult part on the Junior is that one of the areas of the broken teeth has 2 teeth in a row missing.

By the way, I did receive the Bostar qctp, but I used the one from my 9a to try out the Junior. Haven't milled the Bostar mounting bracket to fit yet.

Thanks OT. I appreciate all your input.

Glad to help. My big lathe has eccentrics on the line shaft mounts so that it just cams over to tighten the flat belt when moving the attached levers. Works Good. Next time I am over there I will take some pictures.The self contained motor unit does not use the same system with the turn-buckle. It is a little difficult to tell from the pictures, but see the pictures in my 1st post in this thread, and there is no kind of swivel on the bracket. I was thinking I would make tracks for it to slide in and out. For now, I am able to slide the belt off and on, but the tension is not sufficient if i want to take a heavier cut.

I was able to do the repair with pins I threaded in (instead of welding; no welder) across where the tooth would be on my back gear on my 9a. This one has the teeth missing on the bull gear in 2 locations. The more difficult part on the Junior is that one of the areas of the broken teeth has 2 teeth in a row missing.

By the way, I did receive the Bostar qctp, but I used the one from my 9a to try out the Junior. Haven't milled the Bostar mounting bracket to fit yet.

Thanks OT. I appreciate all your input.

Thank's, that should be very helpful.Glad to help. My big lathe has eccentrics on the line shaft mounts so that it just cams over to tighten the flat belt when moving the attached levers. Works Good. Next time I am over there I will take some pictures.

Made a little progress on the Junior by making the motor assembly pivot. As is seen in one of the photos, a piece of wood is temporarily holding it up on the other end, until I can make the cam system. It is operational now but I don't know if the temporary piece of wood is a problem for now. Belt changes are much easier to make, although the motor assembly takes a bit of strength to lift slightly to move the temporary wood piece.

Now to start contemplating the cam system, to make pivoting the motor easier, and maybe more sturdy.

Now to start contemplating the cam system, to make pivoting the motor easier, and maybe more sturdy.