@mcardoso thank you for all that info. I am going to apply myself to everything you've said this evening and see if I can come up with numbers that I am confident in.

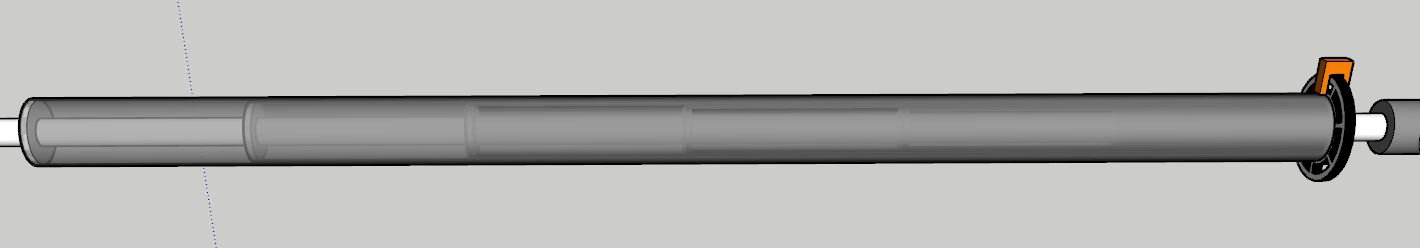

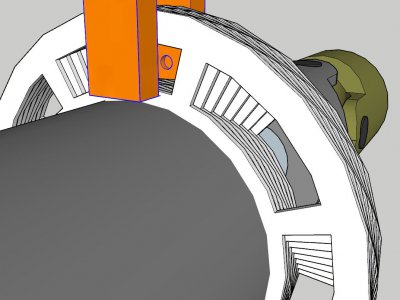

My plan (as described in post #1, everything up in the air right now) does not require high resolution encoders. I did not explain it fully in post #8; it was abbreviated for simplicity. I made it sound as if there will be two optical sensors; one at each end. Actually there will only be one. Instead of having a slotted disk at either end, one will be mounted at "end A", and the other will be mounted directly beside it. "End B" will have a tube fixed to it, running the length of the shaft back to "end A" and connect to the slotted disk. The optical sensor will be reading through both disks at once. The output of the optical sensor will basically be a PWM signal where duty cycle corresponds to torque and period corresponds to speed. Two variables in one signal. It will use use simple slotted disks, maybe 6 slots each, or however many it takes so they don't overlap at maximum twist. I think 6 pulses per revolution is more than enough; the only reason I am planning any more than one pulse per rev, is because I know that the speed (and?) torque in the shaft will be oscillatory any time there is any bend at the cardan joints and i want an average of the data for several sectors of the rotation. I do not believe I need high resolution encoders because I will be precisely measuring

time. A crystal will be running and my microcontroller will be adding up the counts while the photointerrupter is off, and while it's on. Even a lowly 512kHz crystal would give me about 10,000 data points per slot, with 6 slots and running 540rpm.

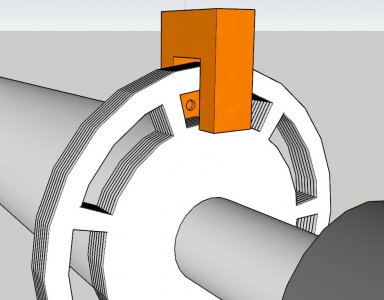

If the above description is not clear, here is an

early version picture of it. When I drew this up I was trying to maximize the difference in on-time vs off-time, so I had several disks which represent about a 15% duty cycle @ 0 torque, and they would fan out like a camera iris until fully closed. I later realized that this is pretty much pointless, with the accuracy of the crystal, I can just use 2 disks which each represent a 50% duty cycle.

I am not going to use the stack of disks and the multiple nested tubes. Just the first disk, the last disk, and the outer tube.

View attachment 360397

View attachment 360398

View attachment 360400

50% (50.0000%) duty cycle will be equal to 0 (0.00) ft×lbs. 0% will be equal to max. Anything in between will be whatever it is (empirically discovered). I can work out the real-world twist degrees per ft×lbs on the bench and scribe graduations on the disks, then verify the values my microcontroller spits out against a timing light.

P.s. I don't know why my last paragraph is in italics and I can't change it.

OK I think I am following...

So the solutions I have written about above are extremely close to the manner of measurement in video #1 in post #1. You'd need to track the positions of two encoders (zeroed out under zero load), query them for their current position simultaneously, compare the readings to determine twist, then use math to calculate torque from twist. You could also sample the tractor side encoder for the speed, multiply that by the torque, and get shaft power. The resolution of torque would be directly related to the resolution of the encoder, the geometry of the shaft (how much it twists for a given torque), and the distance between the encoders (as large as possible). If the distance between the encoders can be increased, then lower resolution (cheaper) encoders can be used.

I am following your plan as well, but would like to offer some dissenting opinions about the method based on my personal hands on experience. First off, feel free to ignore me and try it anyways. Second, prove me wrong, because I'd love to learn new methods like you are discussing.

I believe you are planning to use a "transmissive photomicrosensor" as they are they are commonly called. These output an analog voltage (or sometimes a PWM duty cycle) which corresponds to the amount the sensor is blocked. These work, although they have a few notable drawbacks.

First off, the sensing window is small, forcing you to limit the measuring distance to a very short range (0.25" as an example). In your application, you will want to maximize the distance between the discs as to have a more noticeable twist in the shaft (which even over a good distance like 3 feet might only be a few degrees). The short distance would greatly limit the signal to noise ratio, perhaps to the point where there is no measurable twist between the discs.

Second, the sensor is an optical sensor which is very sensitive to ambient light and will report false signals from even a small amount of stray light - this will drastically reduce your signal to noise ratio. It will also be very sensitive to contamination from dirt, dust, or water.

Finally, the voltage output from these sensors will is nonlinear and will require some mapping tables in code to calibrate the voltages to the actual twist in the shaft. You'll probably end up needing to calibrate the whole thing manually and will end up with a very poor signal to noise ratio.

If you want to go this route, you might want to consider two sensors each with a single disc (just like you have pictured above) positioned as far apart on the shaft as possible. Instead of measuring the exact angular displacement as in my encoder example above, you would be comparing the timing of the light to dark transitions on each of the sensors. In this case an active photosensor with built in amplifier and comparator woud add a lot of robustness to the design. Link below.

Order today, ships today. PM-F25-P – Optical Sensor Through-Beam 0.236" (6mm) Module, Wire Leads, Slot Type from Panasonic Industrial Automation Sales. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

www.digikey.com

By knowing the exact speed of the shaft (read one of the discs like an encoder for speed), you can calculate the angular distance traveled by the shaft during the delay between the light to dark transition on each of the discs. It would be very difficult to align the discs mechanically so each had a light to dark transition at exactly the same time under no load, so it would require a calibration cycle with the shaft running under no-load to determine a nominal delay time between each disc. Once that is defined you can load the shaft and the difference between the measured delay and nominal delay would give you the twist in the shaft. Again once you know this, a bit of math will give you torque and power. The sampling rate of the microcontroller to the sensor input would be the limiting factor in the resolution of torque. You would also need a very accurate measurement of shaft speed, so a disc with a higher pole count would be beneficial to a point although a dozen or so poles would be sufficient rather than the million pulses of the encoder idea.

The downsides are that this could not measure the torque on a non-rotating shaft where the encoder method could, and you rely on a very fast microprocessor to sample the signal for good resolution where that is not a requirement for the encoders. Also it is still an optical system so contamination is a real risk. The sensors I linked are at least waterproof.

www.azom.com

www.azom.com