-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rung fu clone RF-45 ZX45 cnc conversion

- Thread starter jumps4

- Start date

- Joined

- Apr 30, 2012

- Messages

- 2,401

I have the mill tuned and calibrated ready to make swarf

the cabinet still rattles but the mill is smooth and dead on

it is running a 26" x 9" route at 18 ipm in the video

z axis needs nothing the motor makes no difference running up as it does down and tuned in perfect so i dont need the lift cylinders as per my original plan for the 4200 motor it doesnt even notice the weight of the head.

tomorrow I will make something for the first time and measure it after.

now i need to buy a finger brake and shear and start on the enclosure

steve

[video=youtube;0QVDDqW-O8M]http://www.youtube.com/watch?v=0QVDDqW-O8M[/video]

the cabinet still rattles but the mill is smooth and dead on

it is running a 26" x 9" route at 18 ipm in the video

z axis needs nothing the motor makes no difference running up as it does down and tuned in perfect so i dont need the lift cylinders as per my original plan for the 4200 motor it doesnt even notice the weight of the head.

tomorrow I will make something for the first time and measure it after.

now i need to buy a finger brake and shear and start on the enclosure

steve

[video=youtube;0QVDDqW-O8M]http://www.youtube.com/watch?v=0QVDDqW-O8M[/video]

- Joined

- Apr 30, 2012

- Messages

- 2,401

run a first test cut today on a 1" circle and it was .001 out of round i thought i was all set until i checked repeatability in 20" and I'm loosing steps i lost .045 in 20" on average

I tried recalibrating same thing on long runs

I moved mach3 up from 25khz to 35khz and got an improvement, same old problem windows operating system and mach3 not playing well together.

I ordered a UC100 usb controller from cnc4pc ($110.00) to boost my khz from 35 to 100 and then increase my steps per to 20,000

I had planned on a smooth stepper in my original parts list and decided to try it without one. it didnt work good enough, now i'm opting for the uc100 because it is a direct plug in to my breakout board and uses usb for com.

time for the mills first oil change

steve

I tried recalibrating same thing on long runs

I moved mach3 up from 25khz to 35khz and got an improvement, same old problem windows operating system and mach3 not playing well together.

I ordered a UC100 usb controller from cnc4pc ($110.00) to boost my khz from 35 to 100 and then increase my steps per to 20,000

I had planned on a smooth stepper in my original parts list and decided to try it without one. it didnt work good enough, now i'm opting for the uc100 because it is a direct plug in to my breakout board and uses usb for com.

time for the mills first oil change

steve

- Joined

- Jul 7, 2012

- Messages

- 641

Just looked that one up, they certainly pack a lot into a simple DSUB25 shell!

I like the fact that it takes a lot of the load from the computer CPU, so allowing the use of a lower spec computer than would be usual.

You could justify the price on that alone.

M

I like the fact that it takes a lot of the load from the computer CPU, so allowing the use of a lower spec computer than would be usual.

You could justify the price on that alone.

M

- Joined

- Apr 30, 2012

- Messages

- 2,401

7hc

plus the fact i dont have to rewire my panel to use the uc100 it just plugs in to parallel port on the controller and a usb in to it.

made a few small parts for a mercury outboard on it today it is dead on on small moves it looses track on long transitions it's in full use now.

i need to get some sheet metal and design an enclosure.

steve

plus the fact i dont have to rewire my panel to use the uc100 it just plugs in to parallel port on the controller and a usb in to it.

made a few small parts for a mercury outboard on it today it is dead on on small moves it looses track on long transitions it's in full use now.

i need to get some sheet metal and design an enclosure.

steve

- Joined

- Apr 30, 2012

- Messages

- 2,401

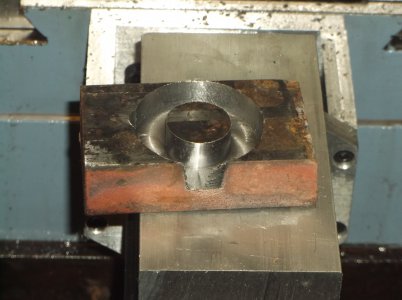

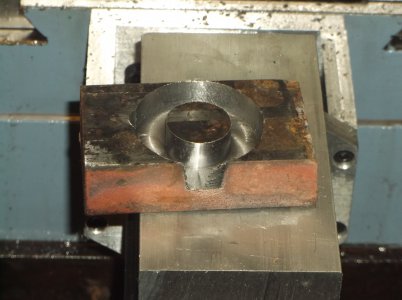

Today went really well a little more tuning while i'm waiting for the new controller and i milled a 1" circle in hot rolled steel for the first time today. it went great I have never had a mill to cut steel like this. i set the machine to 1.9 ipm and a per pass depth of .030 it took 46 minutes to reach a depth of .5 with a $2.00 reground hss endmill i got off ebay. the finish is really smooth and the final piece was 1.001 on x axis and 1.000 on y, it is getting better all the time for accuracy. when It first finished i touched the part and endmill and they were not even warm.

here is a video and a couple pics.

now I have to learn how to mill steel i have never had a mill that would do it before.

steve[video=youtube;0vY1EVfDdNE]http://www.youtube.com/watch?v=0vY1EVfDdNE&feature=youtu.be[/video]

here is a video and a couple pics.

now I have to learn how to mill steel i have never had a mill that would do it before.

steve[video=youtube;0vY1EVfDdNE]http://www.youtube.com/watch?v=0vY1EVfDdNE&feature=youtu.be[/video]

- Joined

- Jun 26, 2012

- Messages

- 76

Steve

couple of questions if I could. What size end mill? What RPM.

The other thing to note is lots of folks say that recutting your chips is a bad thing. I have a Fog Buster mist coolant system I use on my lathes and mills. It keeps every thing kool and the chips blown out of the cut.

You have done a very good job of converting this mill. I think you will be making a lot of chips with it.

Don't know if you have looked at Gwizard.com. They have a great program for figuring best feeds and speeds for lots of materials. I'm to the point I don't make a cut till I check to see what the program says I should use for feed and speed.

Dave

couple of questions if I could. What size end mill? What RPM.

The other thing to note is lots of folks say that recutting your chips is a bad thing. I have a Fog Buster mist coolant system I use on my lathes and mills. It keeps every thing kool and the chips blown out of the cut.

You have done a very good job of converting this mill. I think you will be making a lot of chips with it.

Don't know if you have looked at Gwizard.com. They have a great program for figuring best feeds and speeds for lots of materials. I'm to the point I don't make a cut till I check to see what the program says I should use for feed and speed.

Dave